Steel sheet having enhanced ductility for a molding member, molding member, and method for manufacturing same

A technology for forming parts, steel plates, applied in the direction of manufacturing tools, vehicle parts, chemical instruments and methods, etc., can solve problems such as low elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0068] Steel slabs having the composition shown in Table 1 and formed by vacuum melting were heated in a heating furnace at 1000° C. to 1300° C. for 1 hour, and then hot-rolled to form hot-rolled steel sheets. The hot-rolled steel sheet is cooled at a predetermined temperature in a furnace. Hot rolling is done at a temperature range of 850°C to 950°C, and the cooling temperature in the furnace is 680°C. Thereafter, the hot-rolled steel sheets were pickled and cold-rolled at a reduction ratio of 50%. The cold-rolled steel sheets were annealed at 780°C. Thereafter, the cold-rolled steel sheet was finally continuously annealed at an overaging temperature of 400°C.

[0069] [Table 1]

[0070]

[0071] *IS: Inventive steel, **CS: Comparative steel

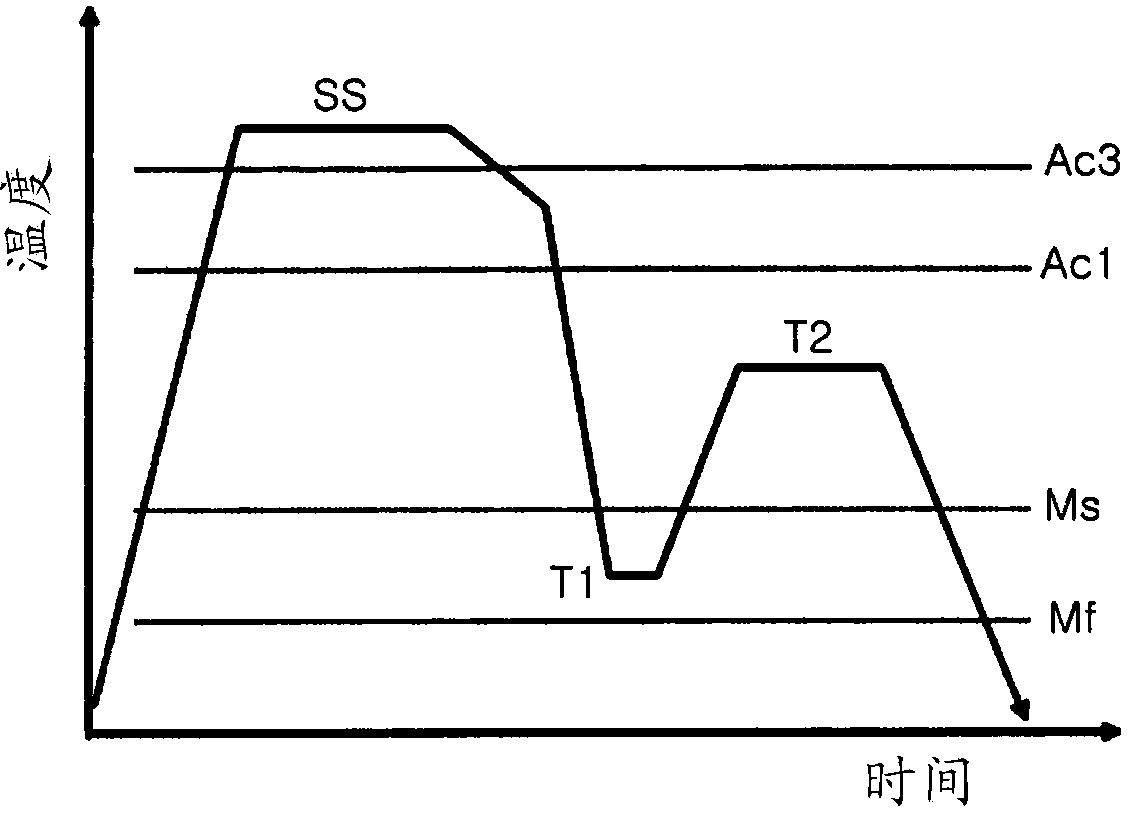

[0072] Such as figure 1 and Table 2 to simulate the heat treatment in the hot stamping process. Specifically, the steel plate fabricated as described above was heated at a rate of 30 °C / s and held at 900 °C (SS) (above Ac3) for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com