Threshing and destemming process that can detect and control the quality of threshing air on-line

A technology for leaf threshing, air separation and quality, which is applied in the direction of comprehensive factory control, electrical program control, tobacco, etc., can solve the problems of less information, difficulty in realizing online detection, poor real-time performance, etc., and achieve automatic control and online detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

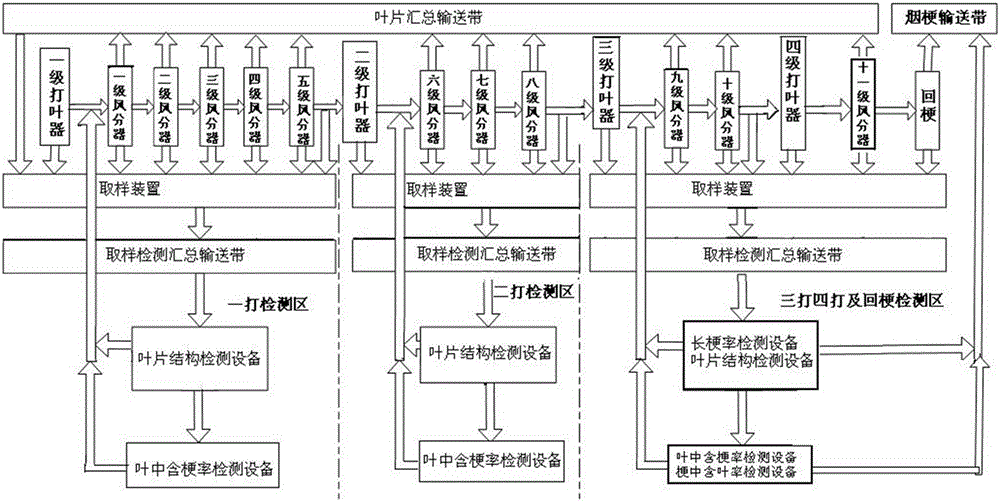

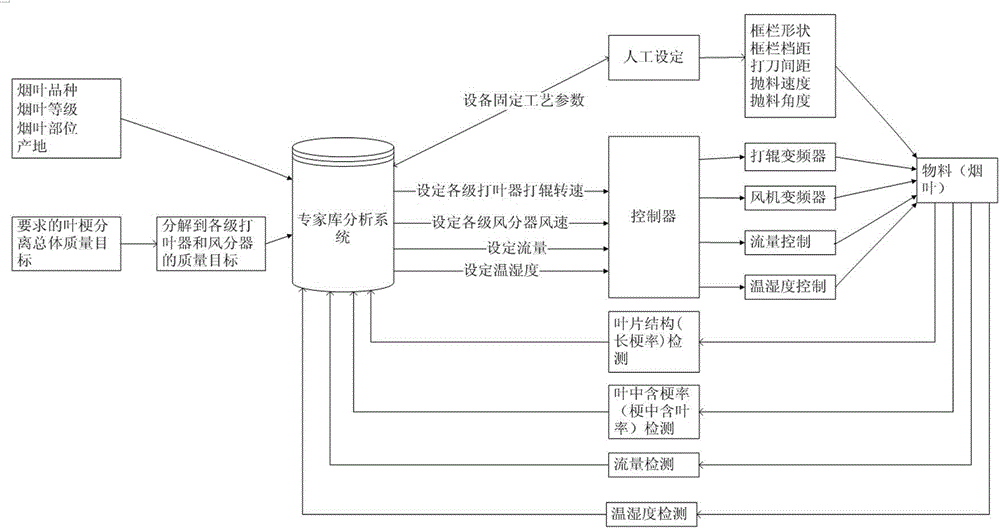

[0013] like figure 1 As shown, the threshing and destemming process that can detect and control the quality of threshing wind in the present invention includes one or more threshing units, and each level of threshing units includes at least one defoliating unit. Defoliator or two or more parallel defoliators, each defoliator is equipped with at least one or more air separators in series behind each defoliator, and the blade summary conveyor belt and the After the last wind separator of the last stage of leaf threshing unit, the tobacco stem conveyor belt that outputs the tobacco stems is respectively equipped with a leaf sampling detection point and a tobacco stem sampling detection point, and each stage of the leaf threshing unit is equipped with a sampling The detection and summary conveyor belt is equipped with a sampling device at the outlet of the leaf topper of each stage of leaf-threshing unit and the outlet of each air separator, and the sample is transported to the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com