Intelligent tunneling, loading and slag storing bin

An intelligent and material storage technology, applied in loading/unloading, transportation and packaging, conveyors, etc., which can solve the problems of secondary stacking of ore ballast, which can only be carried out intermittently, and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

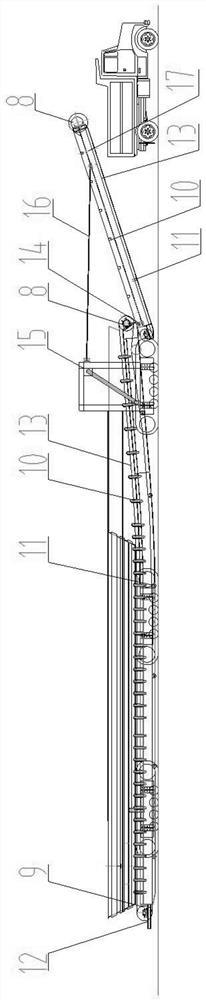

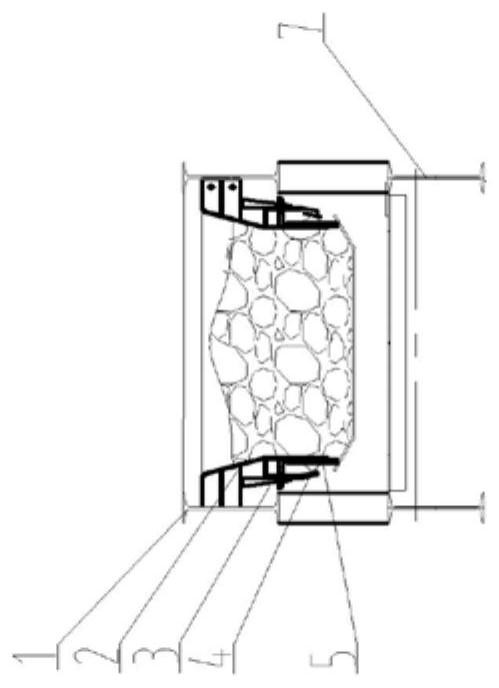

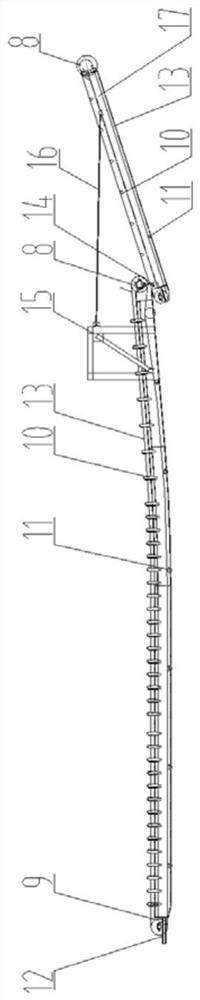

[0017] The preferred specific implementation of the intelligent excavation loading and ballast storage bin of the present invention is as follows: figure 1 As shown, it includes material storage system, walking system, loading system and intelligent control system. see Figure 4 , Figure 5 , the present invention is used in conjunction with the roadheader and its transfer machine, located behind the transfer machine, the transfer machine guide rail 1 is set on the material storage system of the present invention, and the transfer machine is lapped on the transfer machine guide rail 1 of the material storage system.

[0018] The walking system includes multiple sets of walking devices, and a belt feeder is installed on multiple sets of walking devices; and a storage system is installed on at least one set of walking devices at the tail of the belt feeder; There is a set of running gear at the nose to install and connect to the loading belt conveyor. The running device is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com