Shoulder strap of women's underwear and underwear using the same

A technology for women's underwear and shoulder straps, which is applied to shoulder straps, devices for pulling clothes, applications, etc., can solve the problems of small hanging ring structure, easy deformation of hanging rings, and decreased positioning accuracy, so as to improve production efficiency and increase use. Experience, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

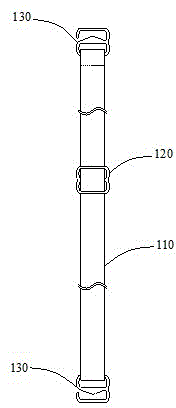

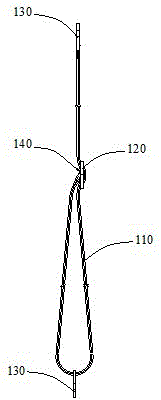

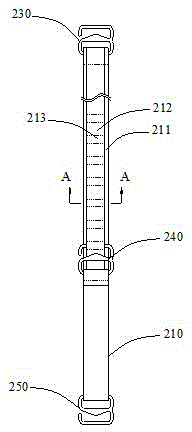

[0034] like image 3 and Figure 4 The shoulder strap 210 of women's underwear shown is in the shape of a belt as a whole. One end of the shoulder strap 210 is connected with a "9" buckle 230, and the other end passes through another "9" buckle 250, and is connected at the end of the shoulder strap 210. There is a third "9" character to deduct 240. The shoulder strap 210 includes an upper layer of webbing 212 and a lower layer of webbing 211. The two layers of webbing are stacked up and down and connected at intervals. The unconnected parts form a number of shoulder strap buckle hanging holes 213 distributed along the shoulder straps 210 at intervals, such as Figure 4 shown. By adjusting the "9" buckle 240 hooked into different hanging holes 213, the overall length of the shoulder strap 210 can be adjusted, thereby achieving the purpose of adjusting the length of the underwear shoulder strap. from Figure 4 It can be seen that on the inner side of the shoulder strap 210 (...

Embodiment 2

[0039] like Figure 10 The shoulder strap 310 of women's underwear shown is in the shape of a belt as a whole. One end of the shoulder strap 310 is connected with a "9" buckle, the other end passes through another "9" buckle, and the end of the end is connected with a "9" buckle. Three "9" button. The shoulder strap 310 includes an upper layer of webbing 312 and a lower layer of webbing 311 , the two layers of webbing are stacked up and down and connected at intervals, and the unconnected parts form a plurality of shoulder strap buckle hanging holes 313 distributed along the shoulder strap 310 at intervals. By adjusting the third "9" buckle hooked into different hanging holes 313, the overall length of the shoulder strap 310 can be adjusted, thereby achieving the purpose of adjusting the length of the underwear shoulder strap. Same as the previous embodiment, this embodiment forms a smooth close-fitting surface on the inner side of the shoulder belt 310, and this side is in d...

Embodiment 3

[0042] The basic structure of this embodiment is roughly the same as the above two embodiments, as Figure 11 As shown, the difference is that the upper webbing 412 of the entire shoulder strap 410 is connected to the lower webbing 411 at intervals, and the formed hanging holes 413 are evenly distributed along the entire shoulder strap 410 . This improvement is mainly to facilitate industrialized large-scale manufacturing. In the process of manufacturing the shoulder strap 410, there is no need to judge where the upper layer of webbing 412 and the lower layer of webbing 411 need to be connected at intervals, that is, the entire shoulder strap 410 is unified with the upper layer of webbing 412. All are connected with the lower ribbon 411 at intervals. The shoulder strap 410 prepared in this way does not need to distinguish the front and back sides when it is inserted into the "9" buckle, which improves the manufacturing efficiency of the shoulder strap 410 . It is also very co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com