Central shaft device of steam type rapid boiling solid separator

A technology of solid separation and central axis, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of user loss, powder cannot be discharged as required, and cannot produce boiling requirements, etc. , to achieve the effect of uniform solid boiling, good sealing and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

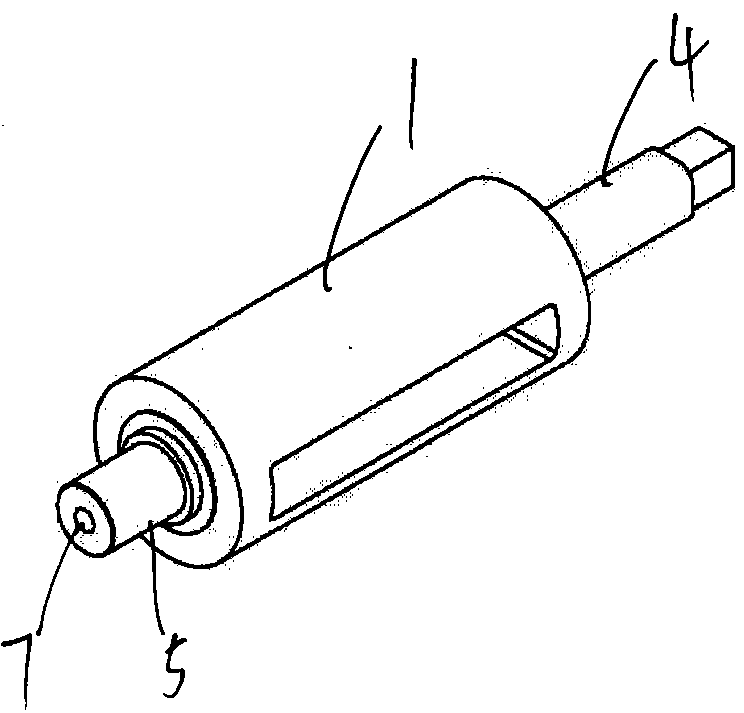

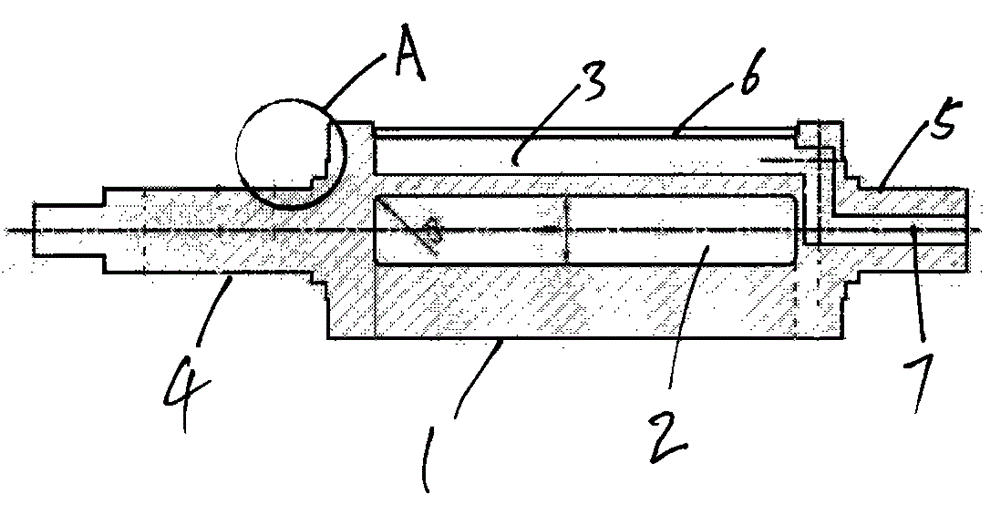

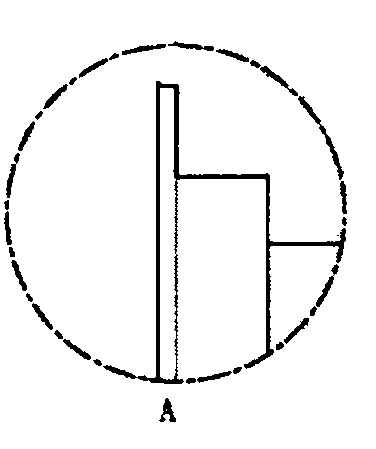

[0010] As shown in the figure, the central axis 1 is a metal cylinder. The central axis 1 is installed in the solid separation body to rotate 180°. There is a discharge bin 2 under the central axis 1. Under the operation of the intelligent control element, the central axis is switched 180° to make the central axis The discharge bin 2 corresponds to the discharge port of the solid separator. The two outlets are the same size to achieve fast discharge; the steam chamber 3 is arranged on the central axis, and the sintered mesh 6 is arranged above the steam chamber 3. When steam is used, the central axis Turn 180° so that the steam chamber port corresponds to the feed port of the solid separator. The steam quickly fills the steam chamber of the valve core, and enters the feed port of the solid separator evenly through the sintered mesh 6. The steam blows directly to the solid in the feed port. To make the solid boil quickly, the two ports have the same size, and the discharge bin 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com