A method for ultrasonically extracting cinnamon oil and its extraction device

An extraction device, ultrasonic technology, applied in the direction of essential oils/fragrances, chemical/physical/physicochemical processes using energy, fat production, etc., to achieve the effects of reducing water content, simple structure, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

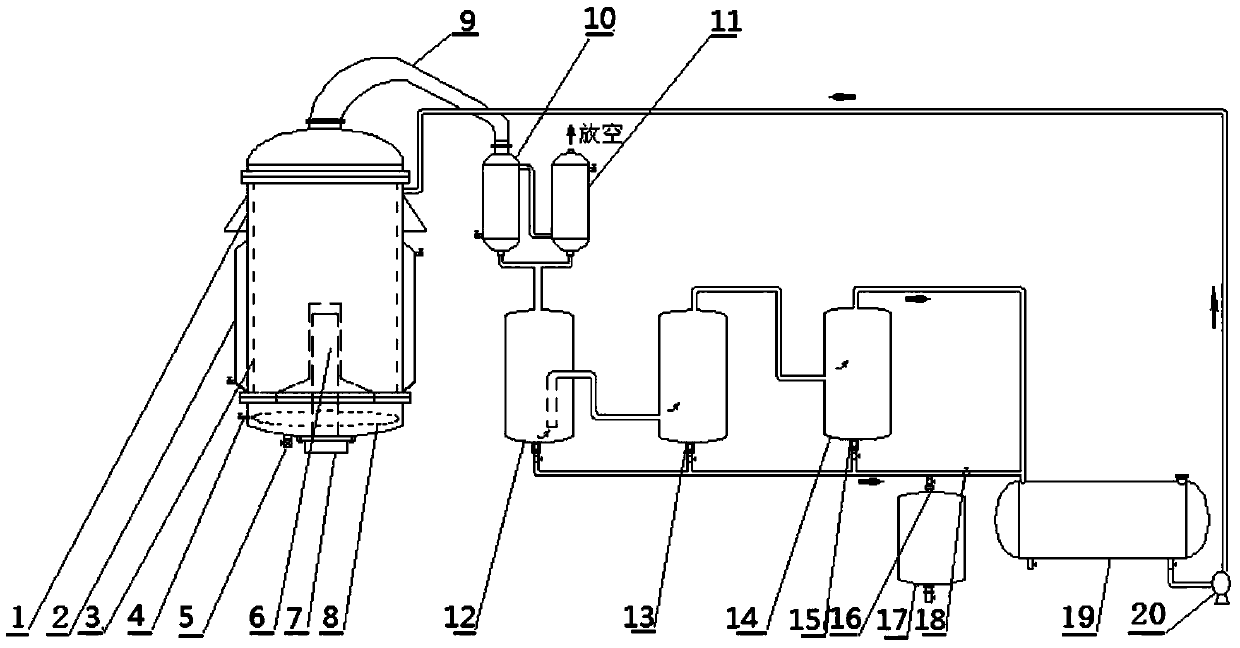

[0035] as attached figure 1 As shown, a device for ultrasonically extracting cinnamon oil includes a reactor 1, a material basket 3, an ultrasonic vibration rod 6, an ultrasonic generator 7, a steam loop 8, a condenser A10, a condenser B11, an oil-water separator A12, and an oil-water separator. Separator B13, oil-water separator C14, oil collection tank 15, water collection tank 19 and pump 20; the material basket 3 is set inside the reactor 1; the ultrasonic generator 7 is fixed on the reactor 1 with a flange The position of the bottom end; the ultrasonic vibrating rod 6 is located in the middle and lower part of the reactor 1; the bottom of the reactor 1 is also provided with a steam ring pipe 8, and the steam ring pipe 8 is provided with a connection steam inlet 4; in the reactor 1 The bottom of the bottom is provided with blowdown outlet 5, and the top of reaction kettle 1 is also provided with steam outlet, and steam outlet is connected with steam outlet pipe 9; Describe...

Embodiment 2

[0038] A method for ultrasonically extracting cinnamon oil, comprising the following steps:

[0039] (1) the cinnamon sticks and leaves of 50kg dried in the shade are chopped to 2cm to obtain the chopped cinnamon raw material;

[0040] (2) put the above-mentioned chopped cinnamon raw material into the material basket, pressurize the water with a slate so that the water just soaks the cinnamon raw material, and soak for 4h;

[0041] (3) First open the upper flange of the reactor, then open the upper head of the reactor, hang the material basket of soaked cinnamon raw materials into the reactor, and use the pump to add the recovered water from the water collection tank into the reactor, Move back the upper head and steam outlet pipe of the reactor, and then pass water vapor from the steam inlet pipe at the bottom of the reactor into the reactor for heating, and start the ultrasonic generator at the same time to control the frequency to 15KHZ, the voltage to 100W, and extract for...

Embodiment 3

[0048] A method for ultrasonically extracting cinnamon oil, comprising the following steps:

[0049] (1) the cinnamon sticks and leaves of 50kg dried in the shade are chopped to 3cm to obtain the chopped cinnamon raw material;

[0050] (2) put the cinnamon raw material cut above into the material basket, pressurize the water with a slate so that the water just soaks the cinnamon raw material, and soak for 6h;

[0051] (3) First open the upper flange of the reactor, then open the upper head of the reactor, hang the material basket of soaked cinnamon raw materials into the reactor, and use the pump to add the recovered water from the water collection tank into the reactor, Move back the upper head and steam outlet pipe of the reactor, and then pass water vapor from the steam inlet pipe at the bottom of the reactor into the reactor for heating, and start the ultrasonic generator at the same time to control the frequency to 20KHZ, the voltage to 80W, and extract for 3 hours after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com