Front pinch roll component for skin lathe

A technology of roller parts and turning machines, which is applied to the accessories of tool holders, turning equipment, turning equipment, etc., can solve the problems of increasing equipment investment costs, low production efficiency, and poor machining accuracy, and achieves simple structure, prevention of rotation, and elimination of The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

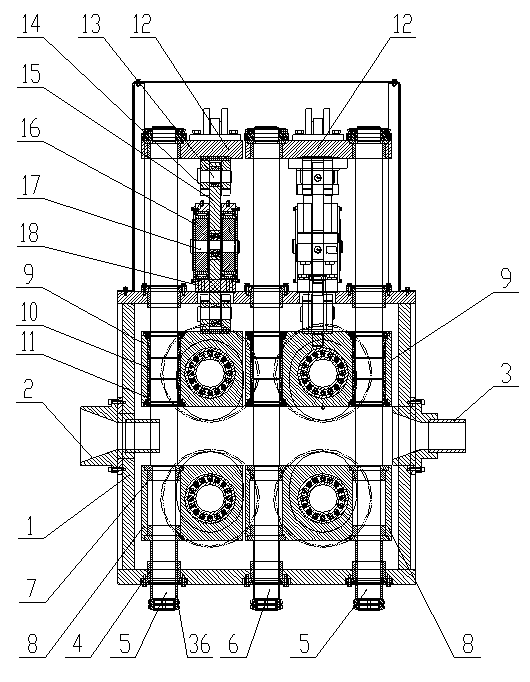

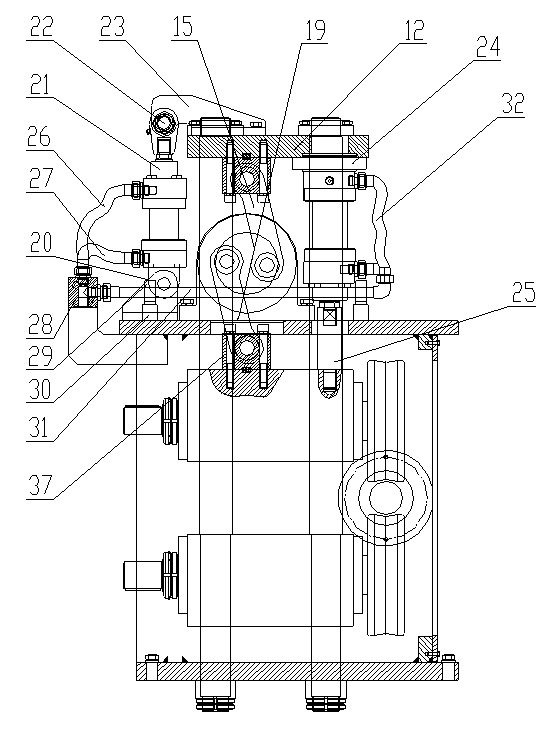

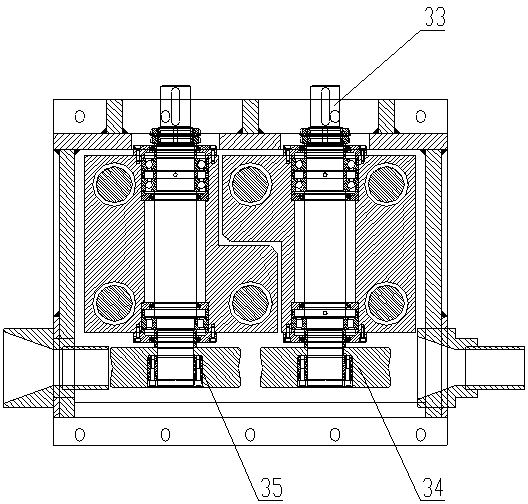

[0054] see Figure 1~Figure 3 , a front pinch roller part of a wagon machine according to the present invention, which includes a frame 1, a front guide sleeve 2 and a rear guide sleeve 3 are respectively arranged on the front and rear sides of the frame 1, and the middle of the frame 1 passes through in the vertical direction. The second guide post 6 is installed, and the first guide post 5 is arranged on the front and rear sides of the second guide post 6 along the vertical direction, and the first guide post 5 and the second guide post 6 are arranged between the frame 1 There is a first guide sleeve 4, a sliding sleeve 37 is set on the lower part of the first guide post 5 and the second guide post 6, and a lower slider 8 and an upper guide post 6 are arranged between the first guide post 5 and the second guide post 6. Slider 9, a sleeve 10 and a second guide sleeve 11 are arranged between the lower slider 9 and the first guide post 5 and the second guide post 6, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com