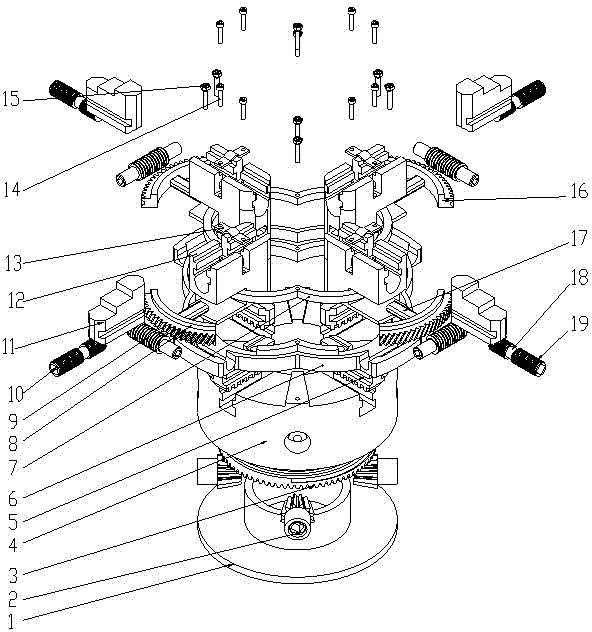

Flexible four-jaw chuck

A four-jaw chuck and chuck technology, which is applied in chucks, turning equipment, tool holder accessories, etc., can solve problems such as insufficient clamping force, reduced machining accuracy, and damaged workpieces, and achieves convenient operation and clamping, Improve machining accuracy and save material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

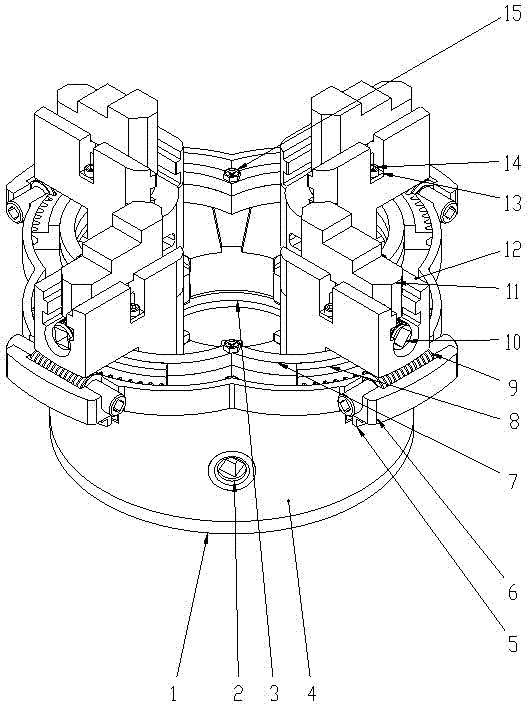

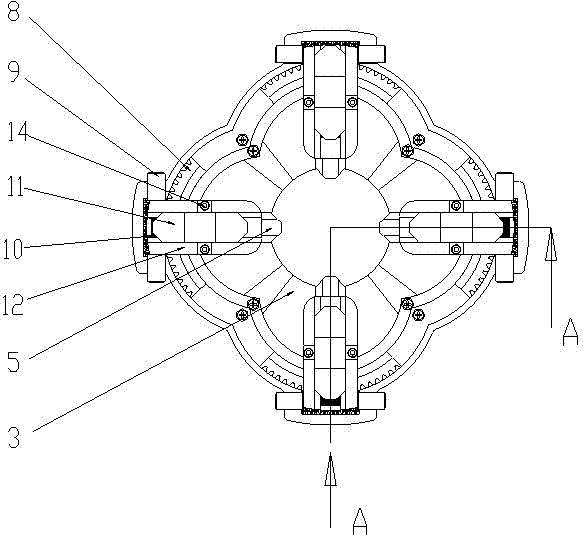

[0019] Such as figure 1 and Figure 4 Shown, a kind of flexible four-jaw chuck comprises chuck body 4, the large cone chuck 3 and bevel gear 2 with helix in chuck body 4, four can be driven by the helix of large cone chuck 3 The linkage lower jaw 5 that moves back and forth radially along the chuck body 4, and the base end cover 1 arranged at the bottom of the chuck body 4, the upper part of the chuck body 4 is fixedly provided with four identical circles by cross-recessed screws 15. The quincunx bracket 6 composed of arcs is also fixed with a quincunx ring 7 that is consistent with the outer contour shape of the quincunx bracket 6;

[0020] A middle piece 12 is articulated on the linked lower jaws 5, and the bottom of the middle piece 12 is extended downward with a pin 20 extending into the linked lower jaw 5. The upper part of the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com