Saw tooth automatic machining device for band saw

An automatic processing and power device technology, applied in the field of machinery, can solve problems such as complex structures, sawtooth widening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

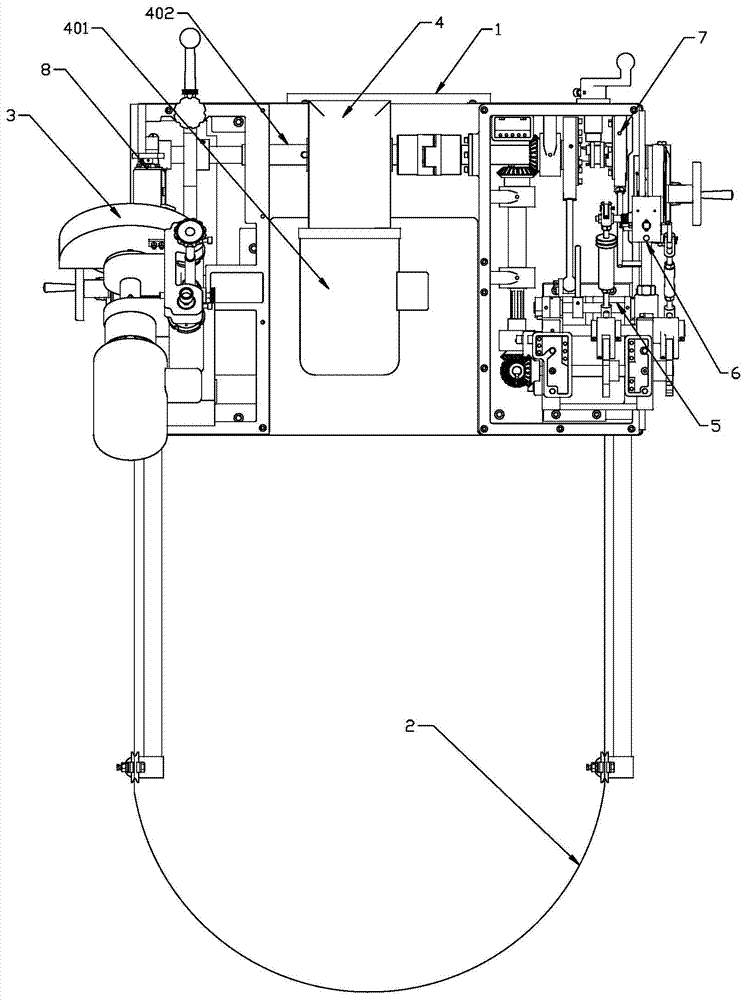

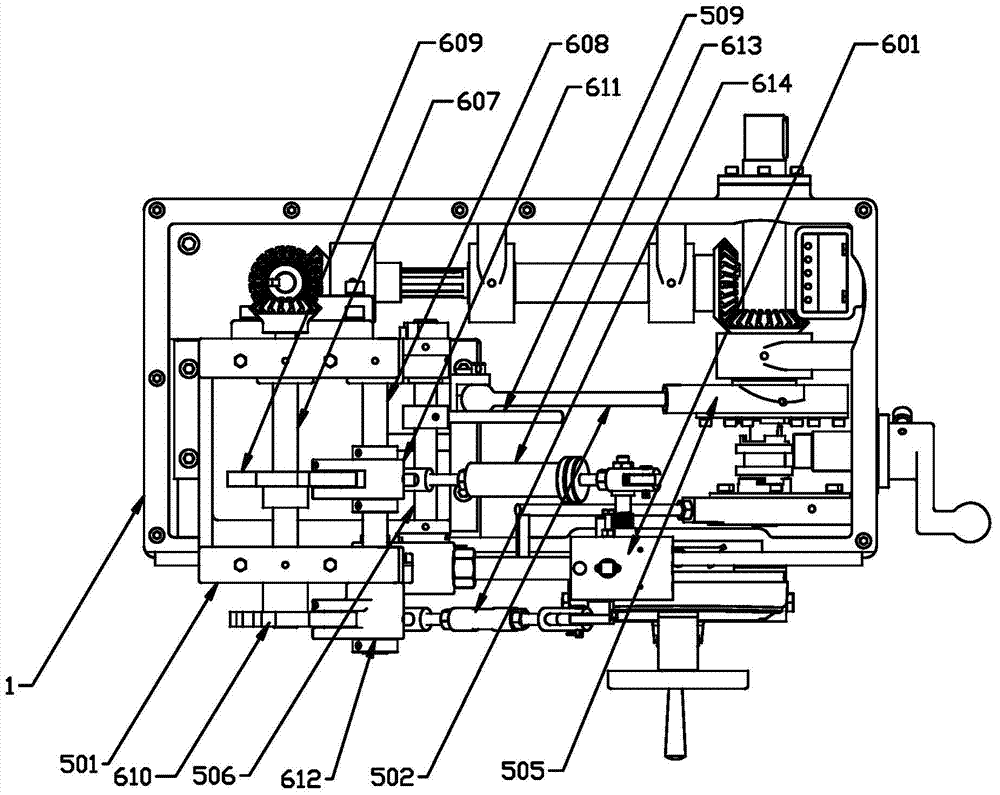

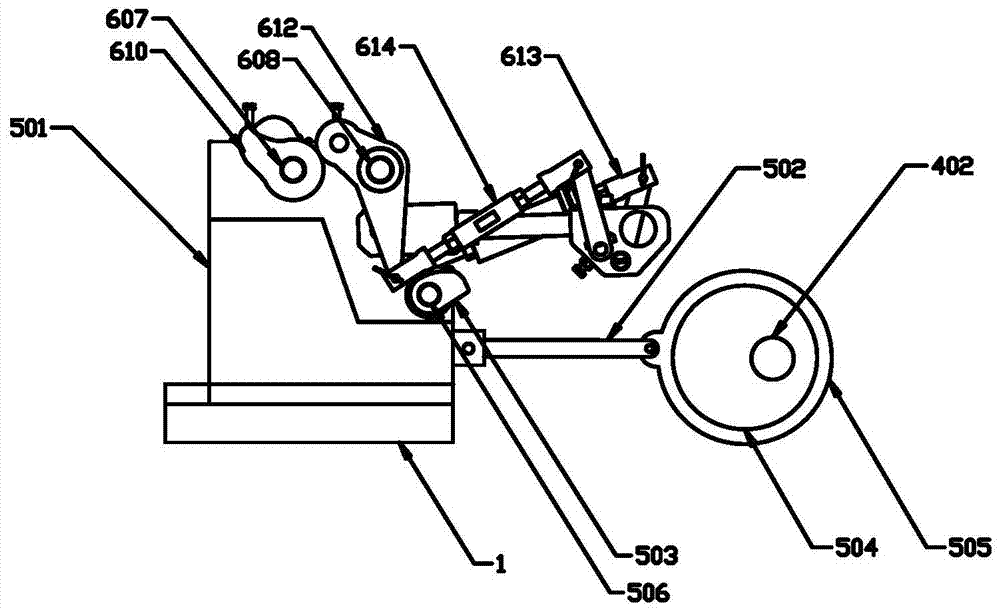

[0036] Such as figure 1 As shown, the band saw sawtooth automatic processing device of the present invention includes a working frame 1 on which the band saw 2 is placed, a moving device installed on the working frame 1 to drive the band saw, and a tooth grinding device 3 for automatically grinding the saw teeth And the power device 4 that provides power also includes a tooth pressing device 5 that automatically presses and widens the sawtooth tip of the band saw.

[0037] The tooth pressing device 5 and the tooth grinding device 3 of this solution are both installed on the working frame 1, and the positions of the two are opposite. Driven by the power device 4, the tooth pressing device 5 applies a certain pressure to the tip of the sawtooth to lower its height. And the width increases, so that the width of the top of the sawtooth is greater than the width of the saw body, so that the band saw is not easily caught by the cut during the cutting process, and the tooth grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com