An automatic magnetic pole tightening screw machine

A screw machine and magnetic pole technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, low efficiency, damage to the gas plate gun head, etc., to save production and assembly costs and work efficiency. The effect of improving and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

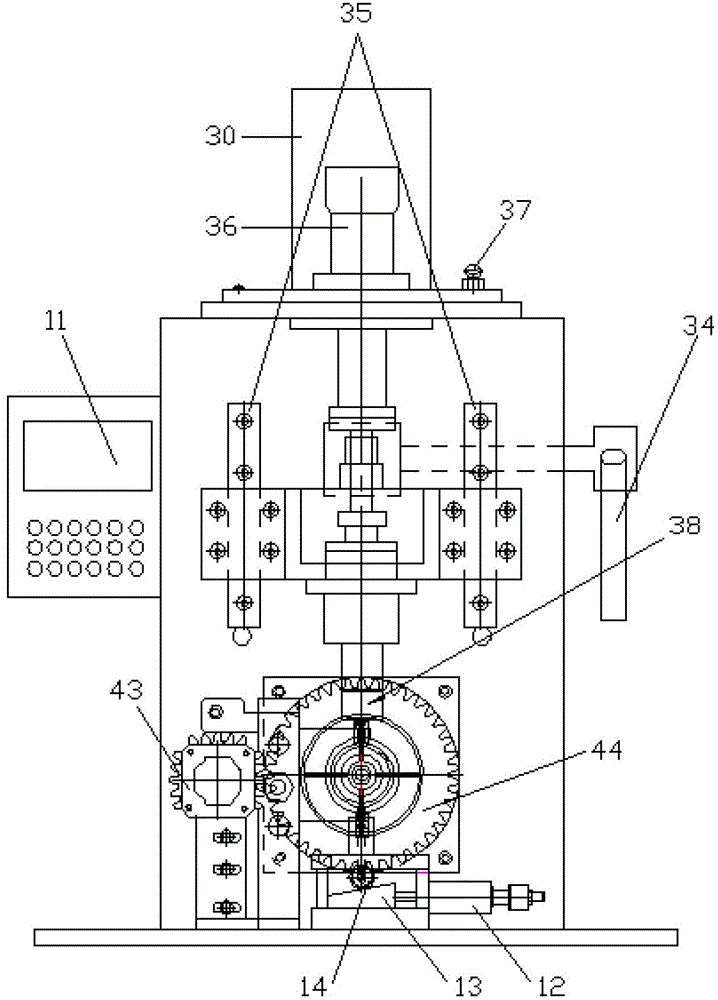

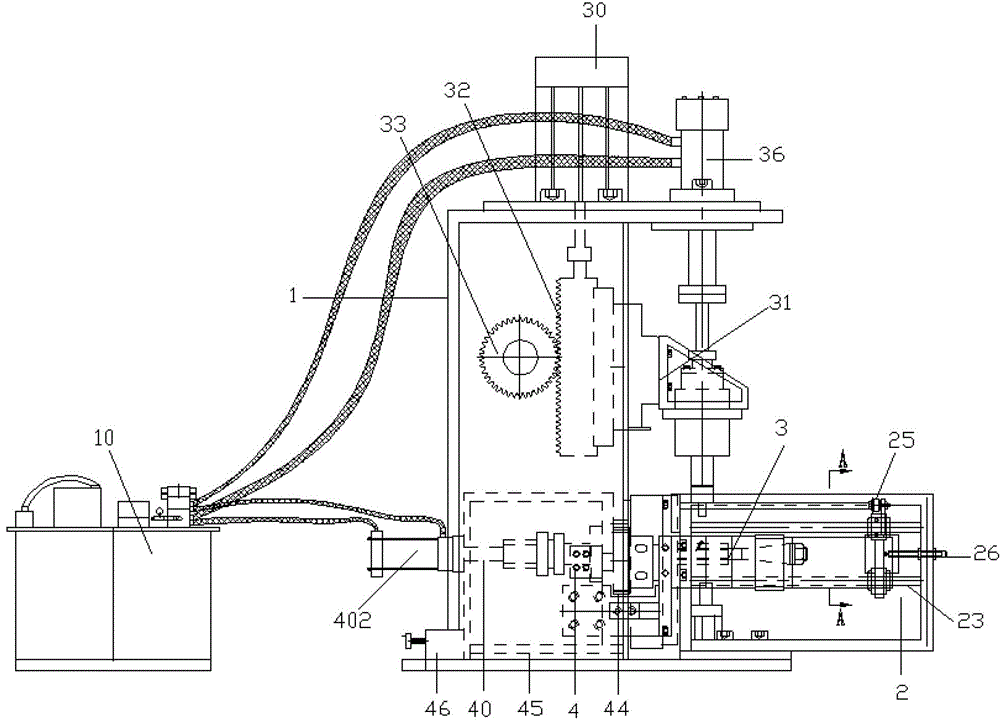

[0027] Combine below Figure 1 to Figure 4 Make specific instructions on the automatic magnetic pole tightening screw machine.

[0028] The automatic magnetic pole tightening screw machine includes a frame 1, the bottom of the frame is provided with a tensioning device 4, the frame is provided with a feeding mechanism 2 in front of the tensioning device, and the upper part of the frame is provided with an automatic magnetic pole tightening screw mechanism 3. In addition, a hydraulic station 10 is provided to supply hydraulic oil to the machine, and a control panel 11 with a liquid crystal touch screen is also provided to control the machine.

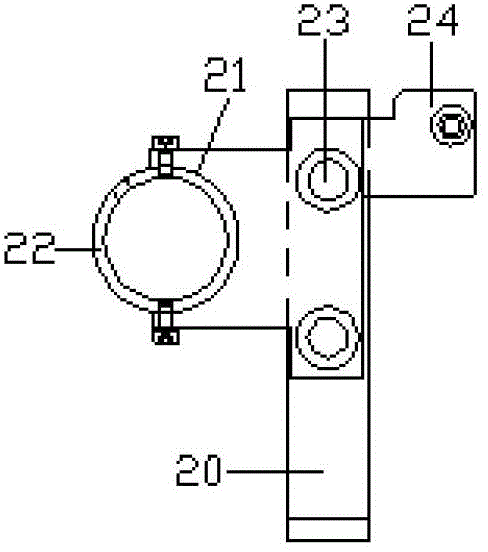

[0029] Wherein, the feeding mechanism 2 includes a feeding guide rail 23 and a feeding fixture 20 arranged on the feeding guide rail, the motor casing assembly is positioned on the feeding fixture 20, and the feeding fixture is driven by a feeding cylinder 25 to slide along the feeding guide rail, The upper and lower sides of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com