Static pressure supporting device for ultra large diameter optical machining

A technology of optical processing and static pressure support, applied in metal processing equipment, optical surface grinders, manufacturing tools, etc., can solve the problems of complex structure of static pressure support device, poor balance of moving parts, and inability to mass production, and achieve high optical The processing support accuracy, the output force accuracy are controllable, and the effect of mass production is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

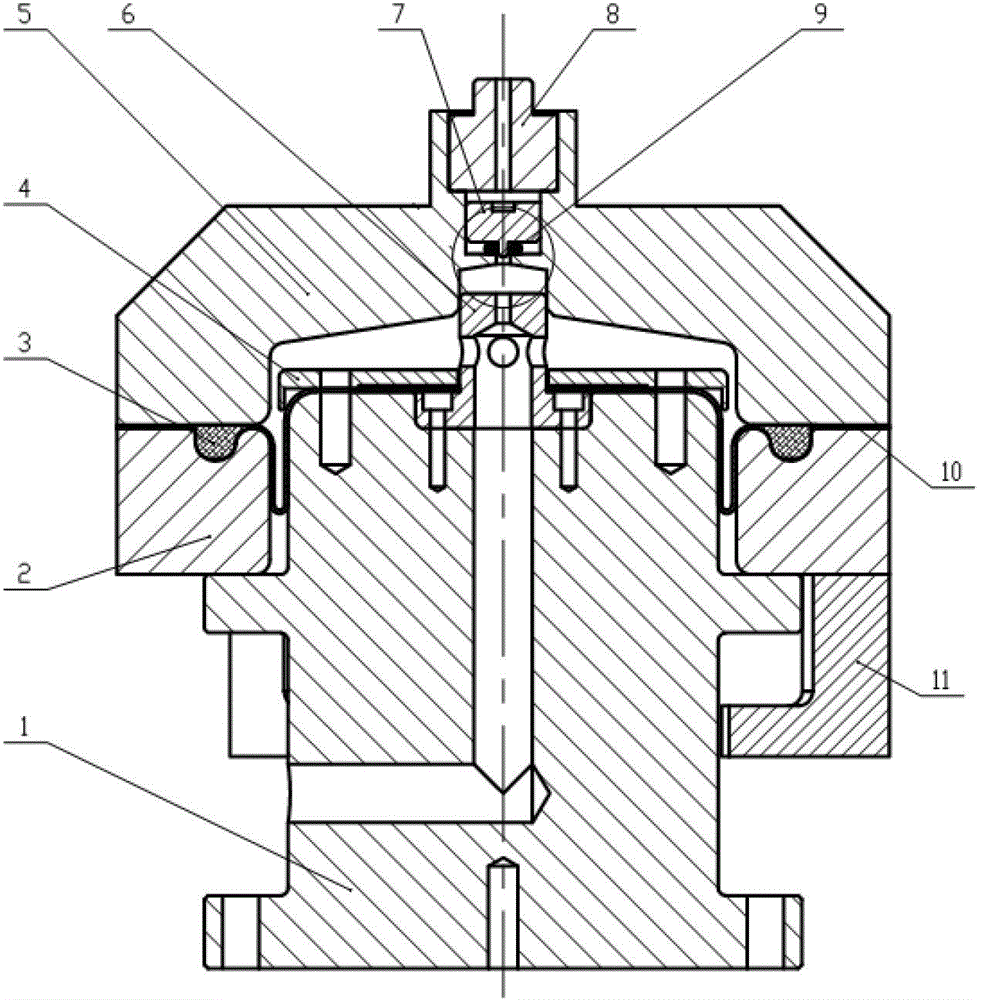

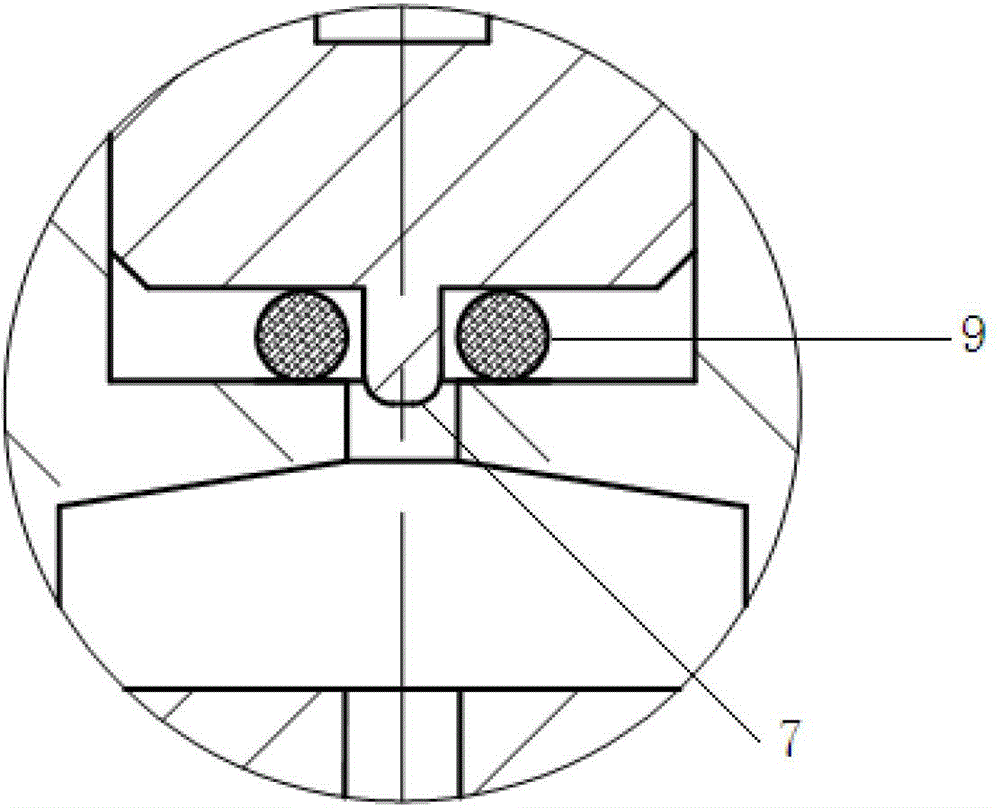

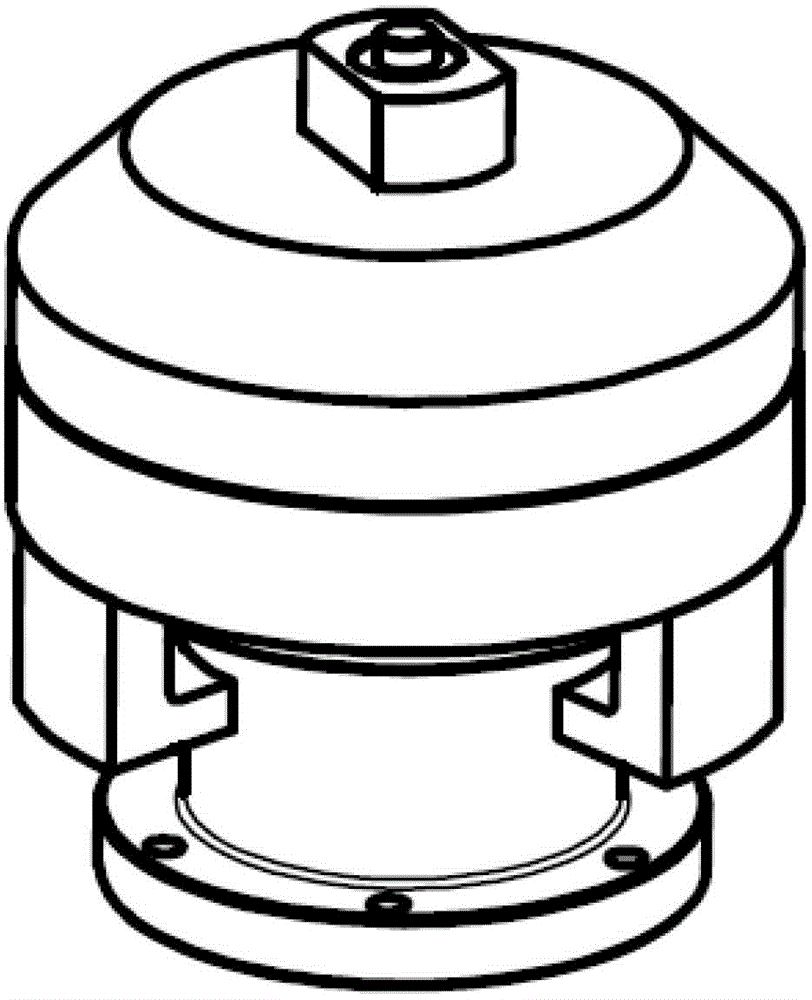

[0020] combine Figure 1 to Figure 3 Describe this embodiment, a hydrostatic support device for ultra-large diameter optical processing, the device includes a piston 1, a gasket 2, a rolling diaphragm 3, a diaphragm pressing plate 4, a cylinder cover 5, a cylinder radial limit Positioning structure 6, screw plug 7, radial limiting structure 8 of the force bearing body, sealing ring 9, diaphragm protection sheet 10 and upper limiting structure 11 of the cylinder body, the side surface of the piston 1 is provided with a horizontal-vertical central hole , the cylinder radial limit structure 6 is a boss through hole structure, the cylinder radial limit structure 6 is connected with the vertical center hole in the horizontal-vertical center hole of the piston 1, and the piston 1 and the gasket 2 pass through the middle The flanges are in contact, the gasket 2 and the cylinder cover 5 are connected through the brim of the rolling diaphragm 3, and the brim of the rolling diaphragm 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com