A kind of edging mechanism specially used for computer speaker net

A technology of edging mechanism and horn net, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, grinding/polishing safety devices, etc. The effect of simple structure, convenient implementation and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

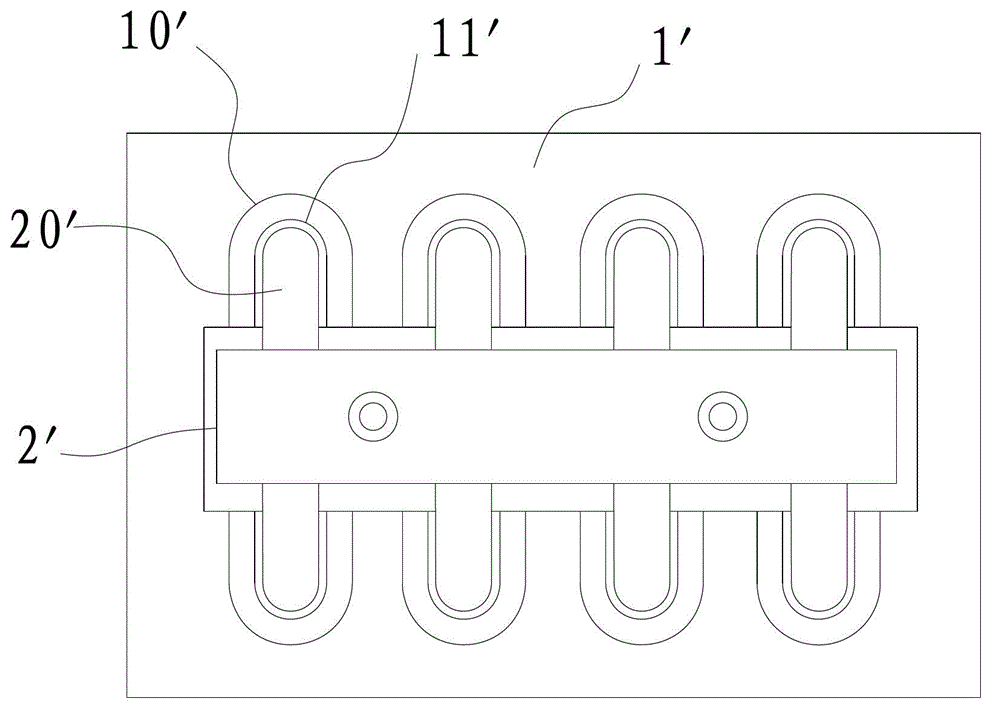

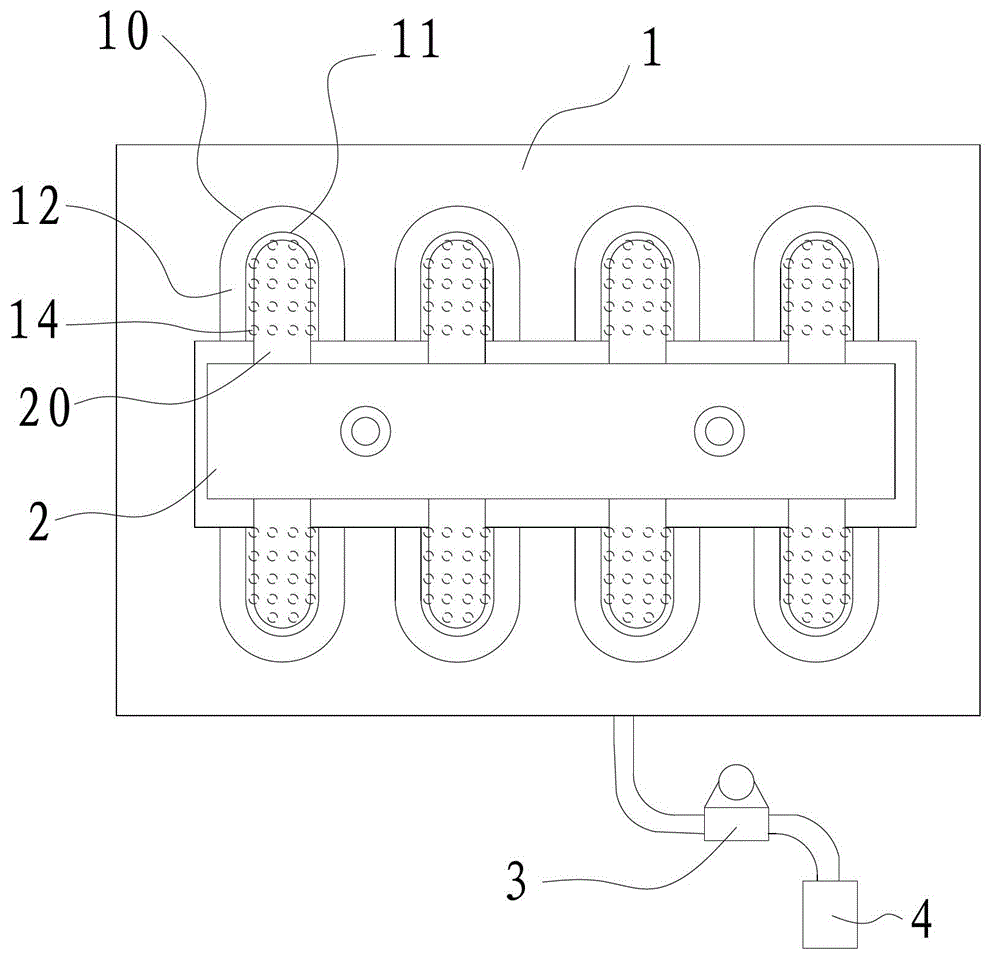

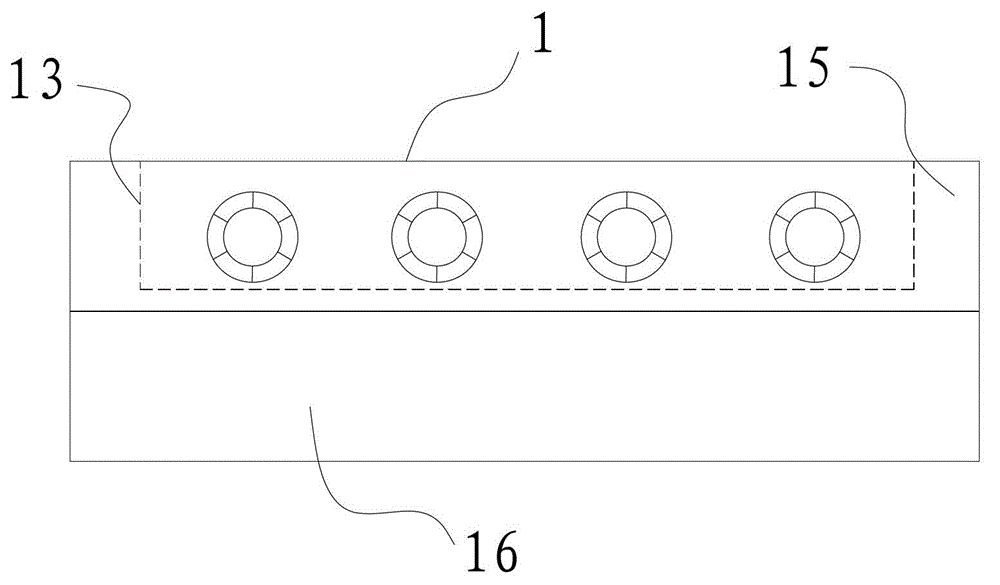

[0015] Such as figure 2 As shown, the edging mechanism dedicated to computer speaker nets provided by this embodiment includes a bottom mold 1 that can be fixed on the worktable and a press mold 2 that is pressed above the bottom mold 1, wherein the bottom mold 1 is provided with A plurality of grooves 10 identical in shape to the horn net are provided with a boss 11 having a width smaller than the width of the horn net in each groove 10, and there is a gap between the circumference of the boss 11 and the sidewall of the groove 10. The channel 12 for the grinding wheel of the edging machine to pass through; the pressing die 2 includes a plurality of pressing blocks 20 respectively pressed on the bosses 11, and the width of the pressing blocks 20 is smaller than the width of the speaker net. Simultaneously, the bottom mold 1 is provided with a cavity 13 inside, and the boss 11 is provided with a plurality of air holes 14 communicating with the cavity 13, and the edging mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com