Organ zippered bag manufacturing method and manufactured organ zippered bag

A production method and zipper bag technology, applied in the manufacture of rigid/semi-rigid containers, container manufacturing machinery, box production operations, etc., can solve the problems that the improved organ zipper bag is difficult to popularize, and achieve simple and smooth production process and airtightness Strong, simplified complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

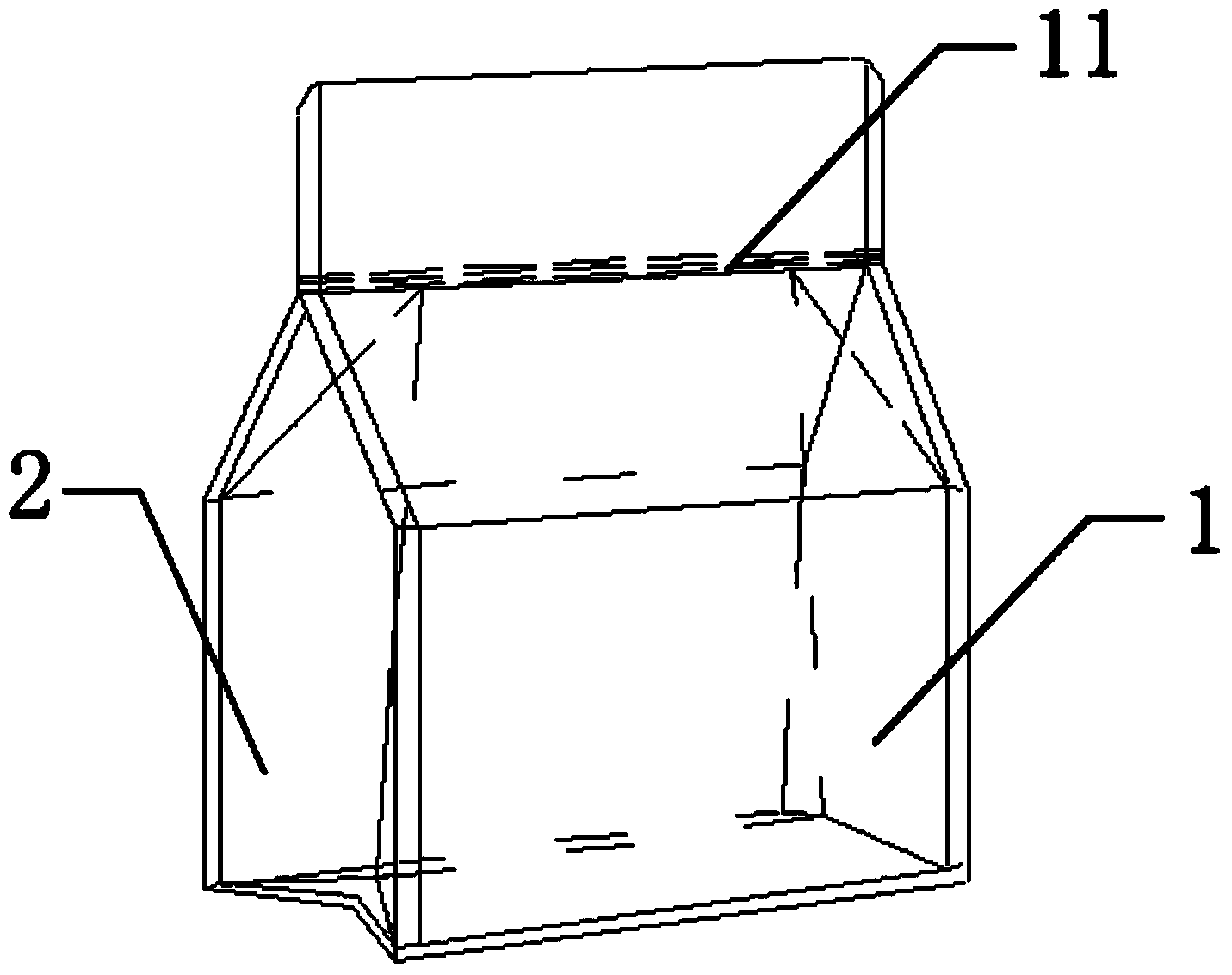

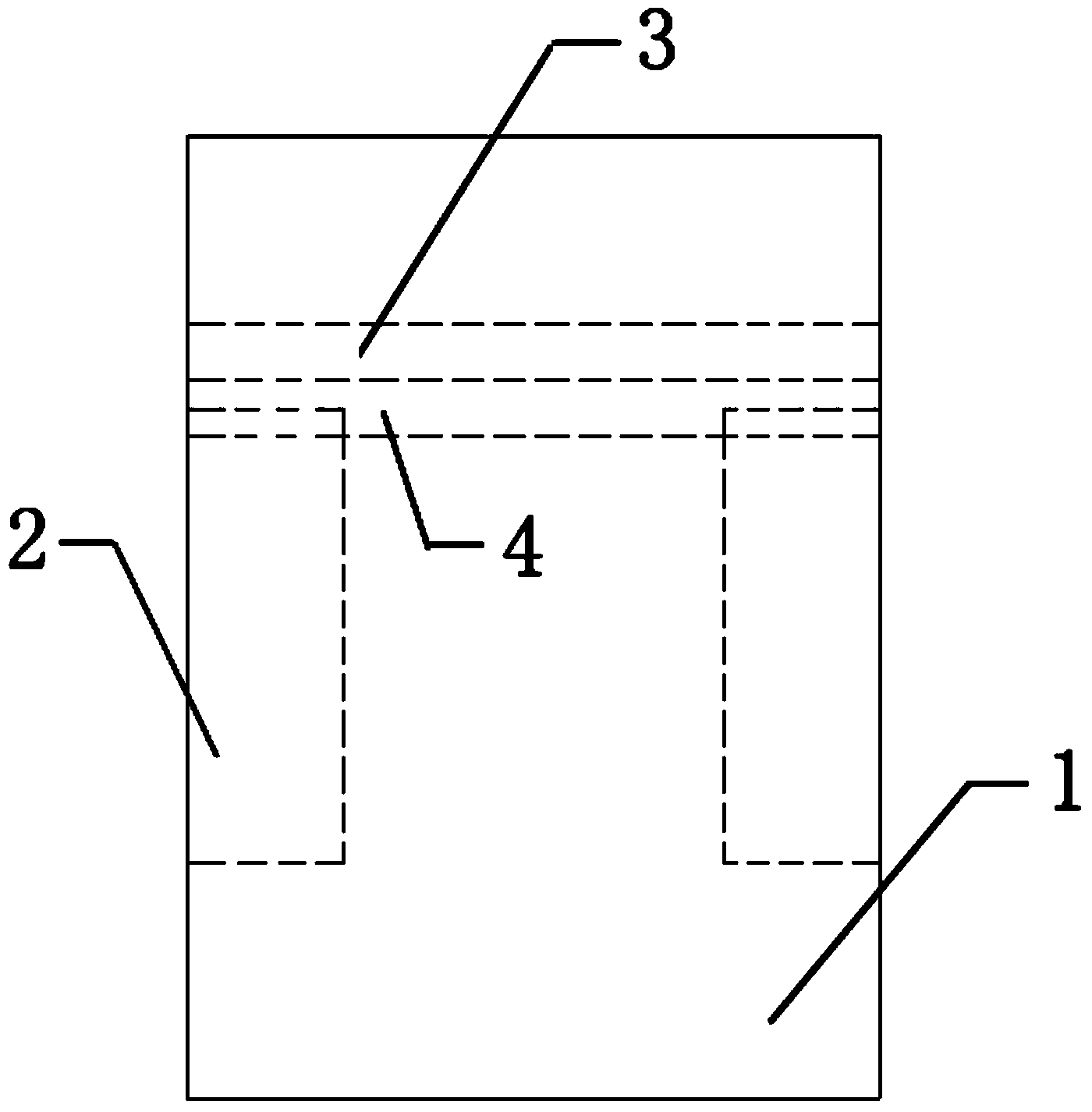

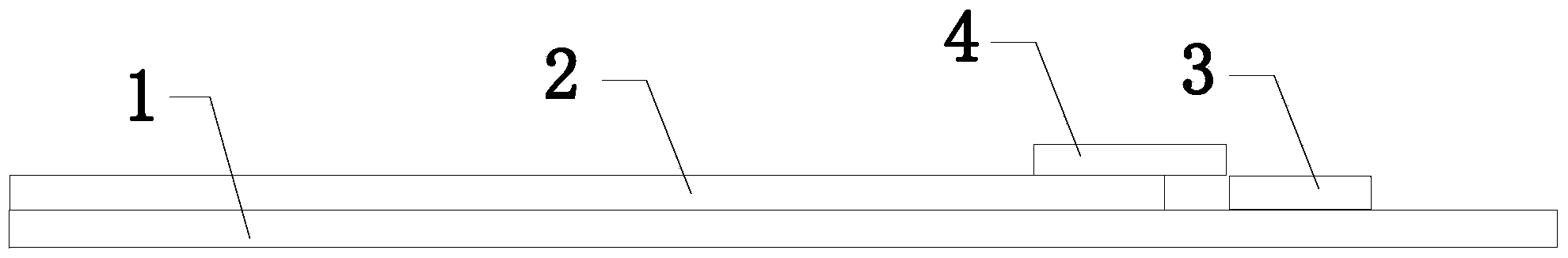

Examples

Embodiment Construction

[0057] The first embodiment of the present invention comprises the following steps:

[0058] A. First, print the desired pattern on both sides of the flat plastic film, and then cut the flat plastic film from the middle with a cutter, so that the flat plastic film is divided into the first flat plastic film and the second flat plastic film, The first and second flat plastic films are respectively conveyed by two sets of conveying guide rollers, and one set of conveying guide rollers sends the first flat plastic film to the heat-sealing knife holder. At this time, the first flat plastic film is placed with the pattern facing down. state.

[0059] B. First print the required pattern on the surface of the side plastic film, and then fold both sides of the side plastic film inward to form the left and right organ surfaces.

[0060] C. Push the left and right organ surfaces to the top of the first plane plastic film from the side, and make the front ends of the left and right orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com