Preparation method of rubber material for preparing high/low temperature resistant automobile gearbox oil hose

A technology for automobile gearboxes and rubber products, which is applied in the field of rubber material preparation, and can solve the problems of difficulty in meeting the increasing requirements of rubber products, changes in hardness, changes in elongation at break, low temperature resistance, and low temperature resistance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the rubber material used to prepare rubber products such as high and low temperature resistant automotive gearbox oil hoses of the present invention comprises the following steps:

[0027] (1) Put rubber raw materials, reinforcing fillers, plasticizers, anti-aging agents, accelerators, and operating aids into the internal mixer for internal mixing, and control the temperature of the rubber below 130°C for debinding. Sheets are released from the rubber machine, cooled, and the masterbatch is obtained;

[0028] (2) Put the masterbatch into the internal mixer, add vulcanizing agent for mixing, control the temperature of the rubber below 80°C to discharge the rubber, and roll out the strips on the open rubber mixer, cool and let it stand for aging to obtain the car transmission for manufacturing. High and low temperature resistant rubber materials used in rubber products such as tank oil hoses.

[0029] In the present invention, the rubber materia...

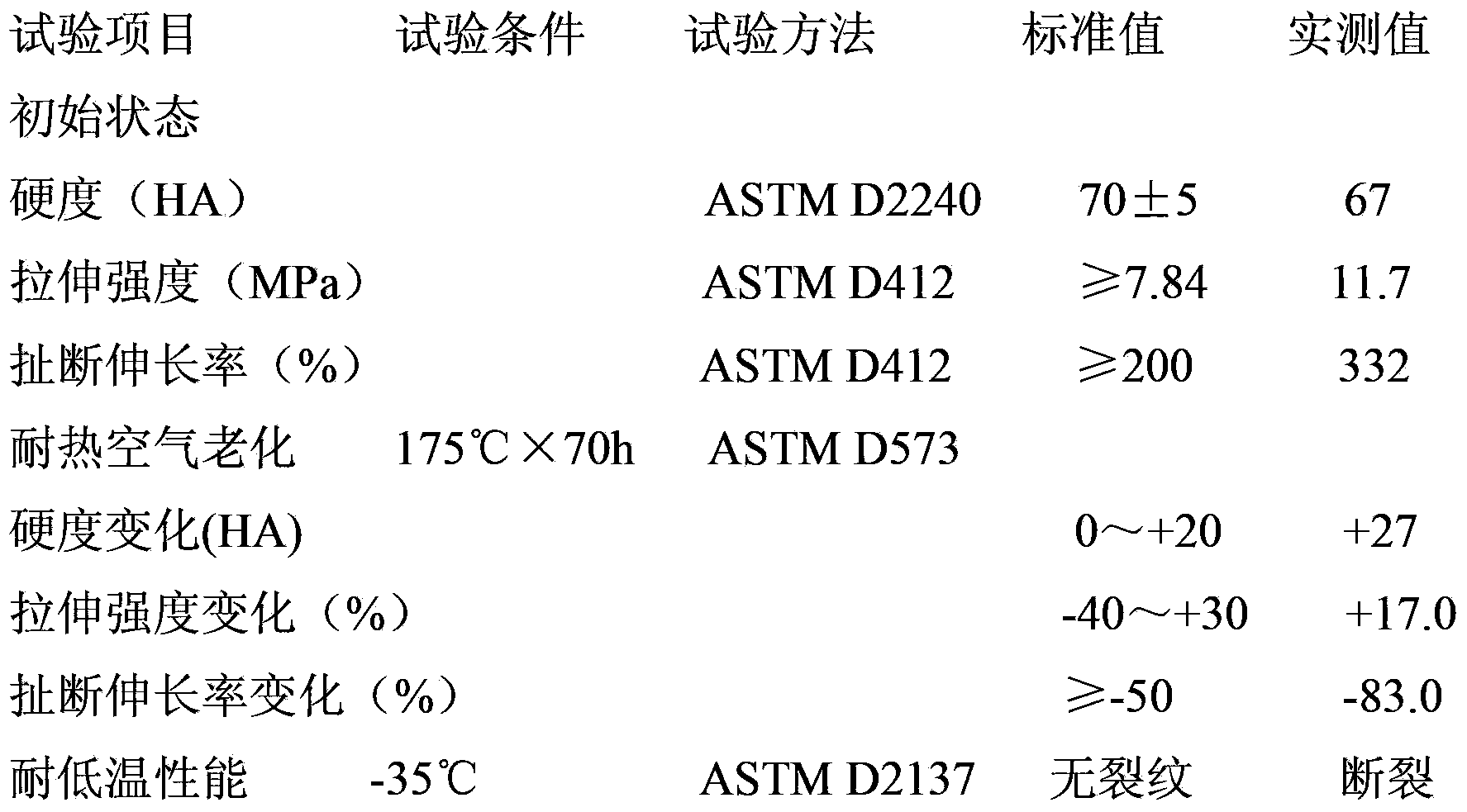

Embodiment 1

[0033] Rubber raw material: acrylate rubber 55.18%;

[0034] Reinforcing filler: quick-pressed furnace black 38.63%;

[0035] Plasticizer: polyester oil 1.66%;

[0036] Antiaging agent: 4,4'-bis(a,a dimethylbenzyl) diphenylamine 1.10%;

[0037] Accelerator: sodium stearate 1.66%;

[0038] Processing aids: stearic acid 0.55%, N-cyclohexylthiophthalimide 0.17%, fatty acid ester 0.83%;

[0039] Vulcanizing agent: sulfur 0.11%, potassium stearate 0.11%;

[0040] The preparation method of the rubber material for preparing high and low temperature resistant automotive transmission oil hose rubber products of the present invention comprises the following steps:

[0041] (1) Control the temperature of the working room of the internal mixer below 130°C, and the rotational speed: 24 rpm, and put the rubber raw materials, reinforcing fillers, plasticizers, anti-aging agents, accelerators, and operating aids in the formula into the internal mixing In the machine, the mixing time is 5...

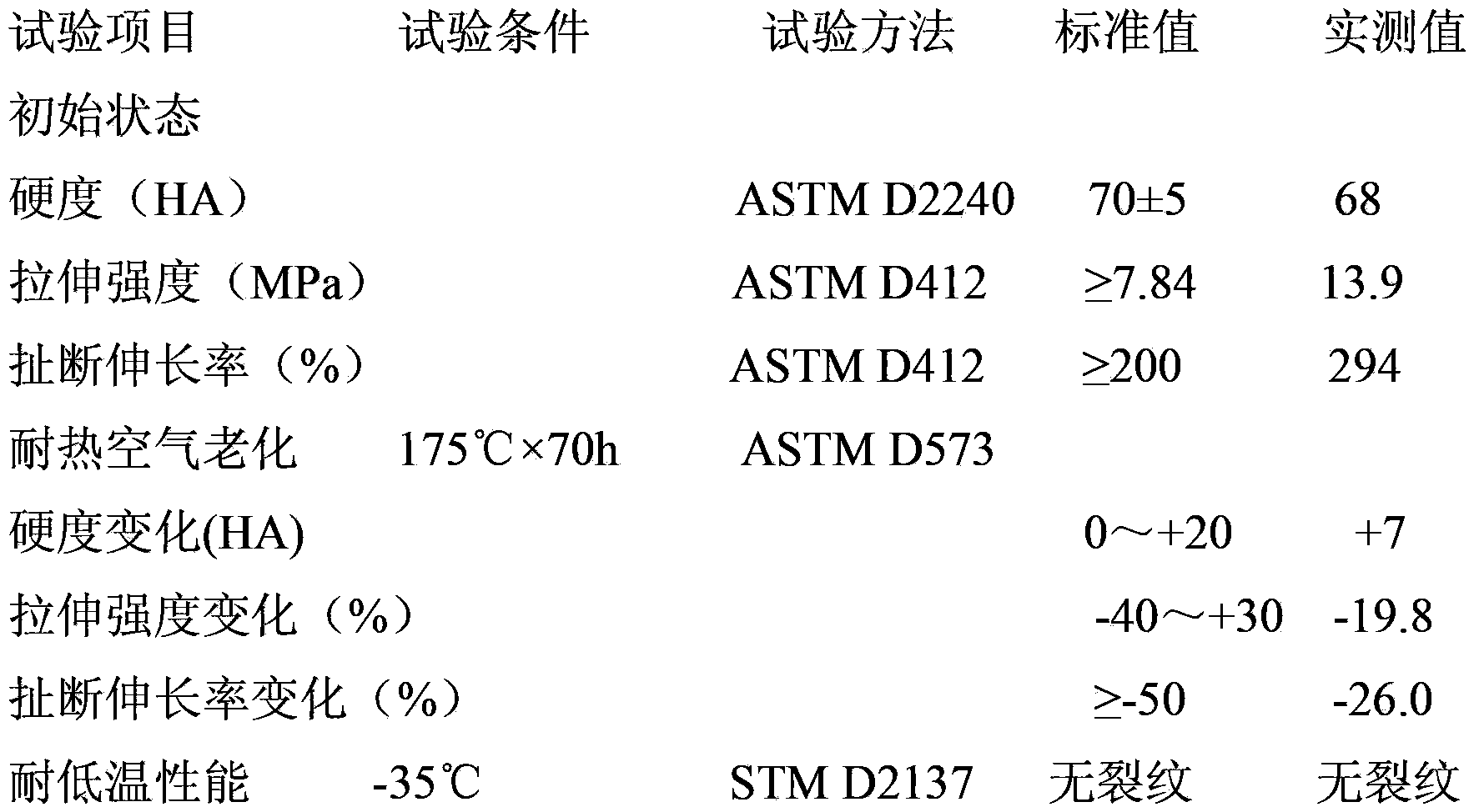

Embodiment 2

[0047] Rubber raw material: Acrylic rubber 55.40%;

[0048] Reinforcing filler: quick-pressed furnace black 38.61%;

[0049] Plasticizer: polyester oil 1.62%;

[0050] Antiaging agent: 4,4'-bis(a,a dimethylbenzyl) diphenylamine 1.06%;

[0051] Accelerator: sodium stearate 1.67%;

[0052] Processing aids: stearic acid 0.50%, N-cyclohexylthiophthalimide 0.16%, fatty acid ester 0.78%;

[0053] Vulcanizing agent: sulfur 0.10%, potassium stearate 0.10%;

[0054] The preparation method of the rubber material for preparing high and low temperature resistant automotive transmission oil hose rubber products of the present invention comprises the following steps:

[0055] (1) Control the temperature of the working room of the internal mixer below 130°C, and the speed: 24 rpm, and put the rubber raw materials, reinforcing fillers, plasticizers, anti-aging agents, accelerators, and operating aids in the formula into the internal mixing In the machine, the mixing time is 5-6 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com