Preparation method of rubber material for preparing high temperature-resistant automobile cooling hose

A kind of rubber material, automobile cooling technology, applied in the direction of hose, pipe, mechanical equipment, etc., can solve the problem of low temperature resistance, hardness change, elongation at break performance does not meet the requirements, it is difficult to meet the increasing requirements of rubber products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method for the rubber material that is used to prepare high-temperature-resistant automobile cooling hose of the present invention, it comprises the steps:

[0026] (1) Cool the internal mixer with water, put rubber raw materials, reinforcing fillers, plasticizers, active agents, anti-aging agents and accelerators into the internal mixer for internal mixing, and control the rubber temperature below 160°C for internal mixing. Debinding, sheeting and cooling on an open rubber mixer to obtain masterbatch;

[0027] (2) Put the masterbatch into the internal mixer, add vulcanizing agent evenly for mixing, control the temperature of the glue below 100°C to discharge the glue, and make strips on the open rubber mixer, cool and stand for aging to obtain the car for manufacturing High temperature resistant rubber material used for rubber products such as coolant system hoses.

[0028] In the present invention, the rubber material comprises the following component...

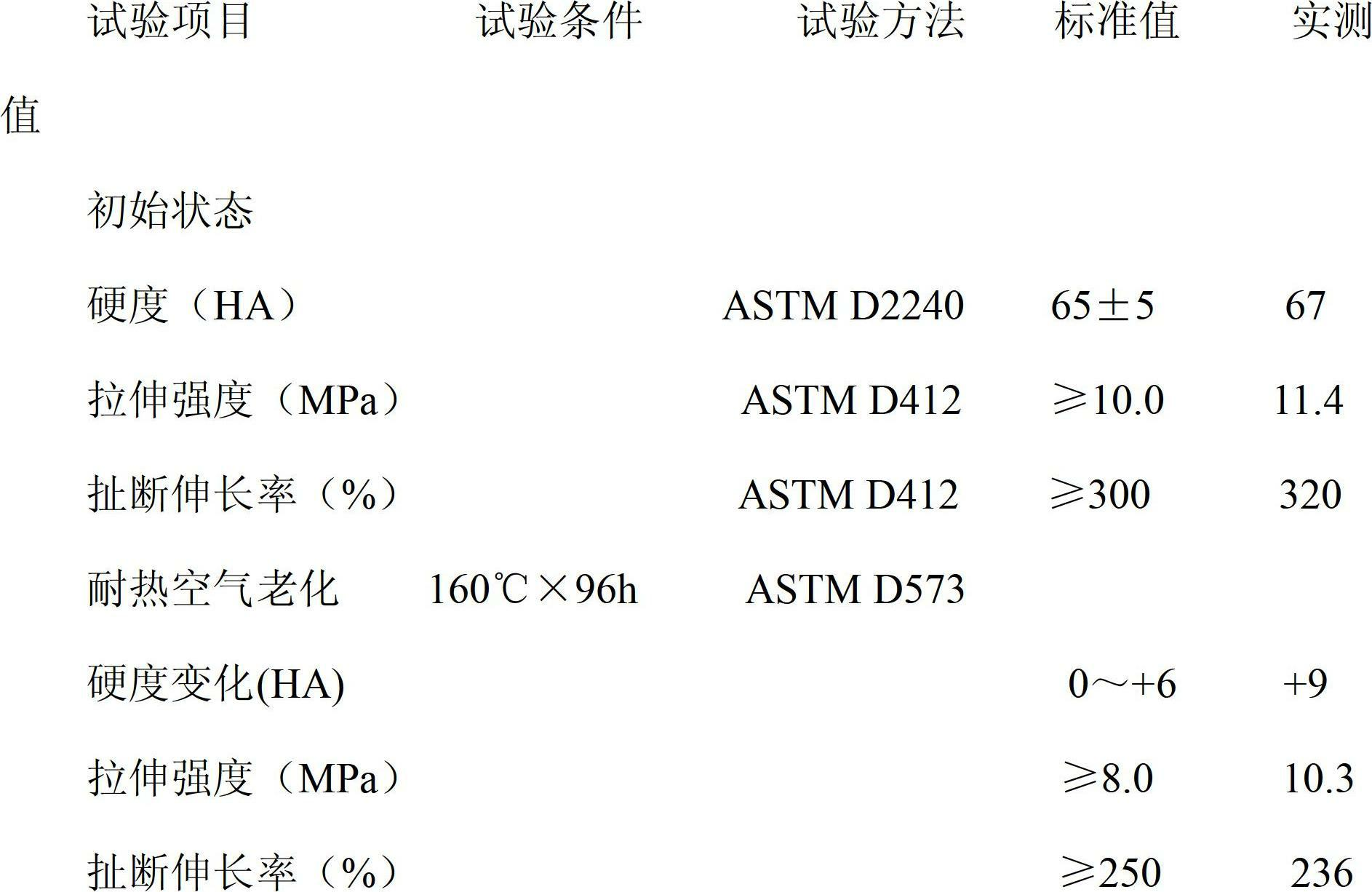

Embodiment 1

[0033] Rubber raw material: EPDM rubber 41.32%;

[0034] Reinforcing filler: 18.60% of quick-pressed furnace black, 12.40% of non-polluting high-definition semi-reinforcing furnace black, and 10.33% of silicon powder;

[0035] Plasticizer: paraffin oil 11.98%;

[0036] Active agent: magnesium oxide 1.65%;

[0037] Antiaging agent: 0.62% of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.62% of 2-mercaptobenzimidazole;

[0038] Accelerator: triallyl isocyanurate 1.03%;

[0039] Vulcanizing agent: dicumyl peroxide 1.45%;

[0040] Specifically include the following steps:

[0041] (1) Cool the internal mixer with water, control the temperature of the internal mixer studio to be greater than 100°C, and the rotation speed: 32 rpm, and mix the rubber raw materials, reinforcing fillers, plasticizers, active agents, and anti-aging agents in the formula 1. The accelerator is put into the internal mixer, and the internal mixing takes 5.5 minutes. The glue temperature is controlled ...

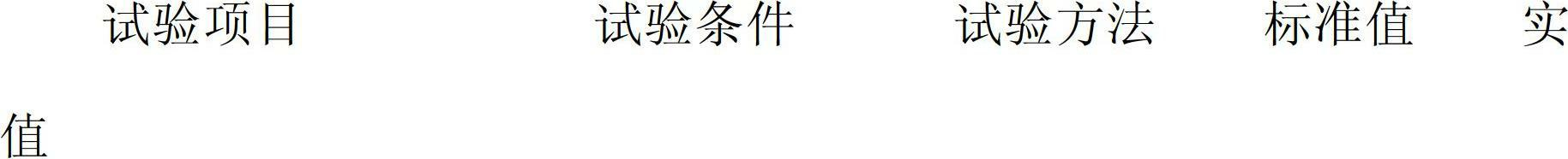

Embodiment 2

[0048] Rubber raw material: EPDM rubber 40.82%;

[0049] Reinforcing filler: 18.59% of quick-pressed furnace black, 12.53% of non-polluting high-definition semi-reinforcing furnace black, and 10.50% of silicon powder;

[0050] Plasticizer: paraffin oil 12.16%;

[0051] Active agent: magnesium oxide 1.66%;

[0052] Antiaging agent: 0.65% of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.65% of 2-mercaptobenzimidazole;

[0053] Accelerator: triallyl isocyanurate 1.02%;

[0054] Vulcanizing agent: dicumyl peroxide 1.42%;

[0055] Specifically include the following steps:

[0056] (1) Cool the internal mixer with water, control the temperature of the internal mixer working room to be greater than 100°C, and the speed to be 32 rpm, and promote the rubber raw materials, reinforcing fillers, plasticizers, active agents, and anti-aging agents in the formula. Put the agent into the internal mixer, the internal mixing takes 5 minutes, the glue temperature is controlled below 160°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com