Preparation method of automobile water pipe rubber material without toluene spray

A rubber material and toluene-spraying technology, which is applied in the field of rubber material preparation for automobile water pipes without spraying toluene, can solve problems such as non-conformity and toluene residue, meet environmental protection requirements, and improve the effect of peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

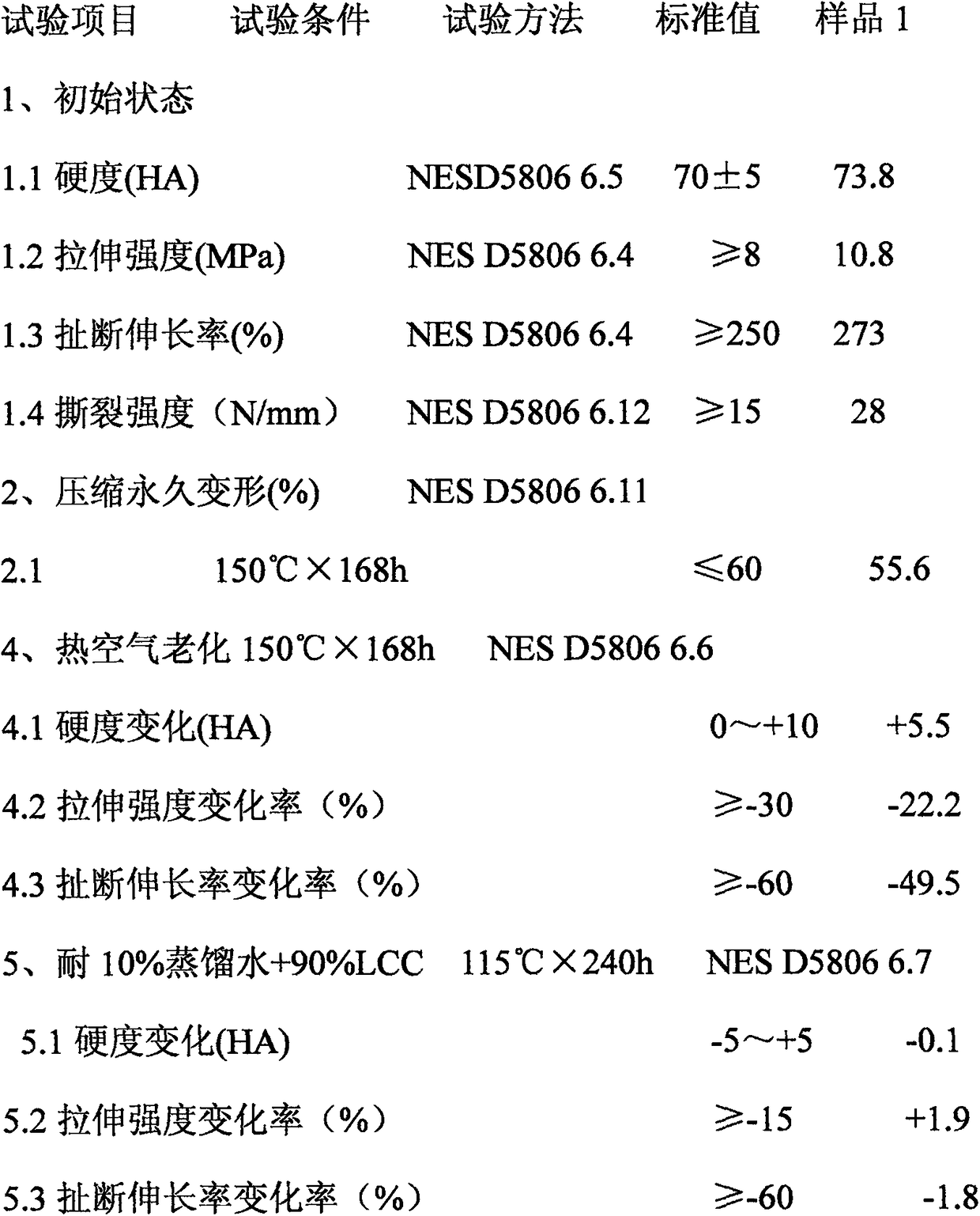

[0033] Product name: Rubber material for automobile water pipes without spraying toluene;

[0034] Formula: formula unit is percentage by weight;

[0035] Rubber raw material: EPDM rubber, 32.69%;

[0036] Reinforcing filler: quick-pressed furnace black, 21.25%; non-polluting high-strength semi-reinforced furnace black, 5.88%; activated calcium carbonate, 14.71%; modified stone powder, 6.54%;

[0037] Plasticizer: paraffin oil, 11.44%;

[0038] Active agent: zinc oxide, 1.63%; stearic acid, 0.33%;

[0039] Crosslinking agent: N, N-m-phenylene bismaleimide, 0.56%; modified metal dimethacrylate, 1.31%;

[0040] Vulcanizing agent: dicumyl peroxide, 1.14%; sulfur 0.10%;

[0041] Antiaging agent: 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0.46%;

[0042] Processing aids: polyethylene glycol, 1.31%;

[0043] Dispersion aid, polymer fatty acid emulsion (trade name WB212), 0.65%;

[0044] preparation:

[0045] Preparation conditions, equipment

[0046] Ambient air pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com