Novel slide guide rail

A sliding guide, a new type of technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of unstable motion accuracy, easy crawling at low speed, and large wear, and achieve simple structure, long service life and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

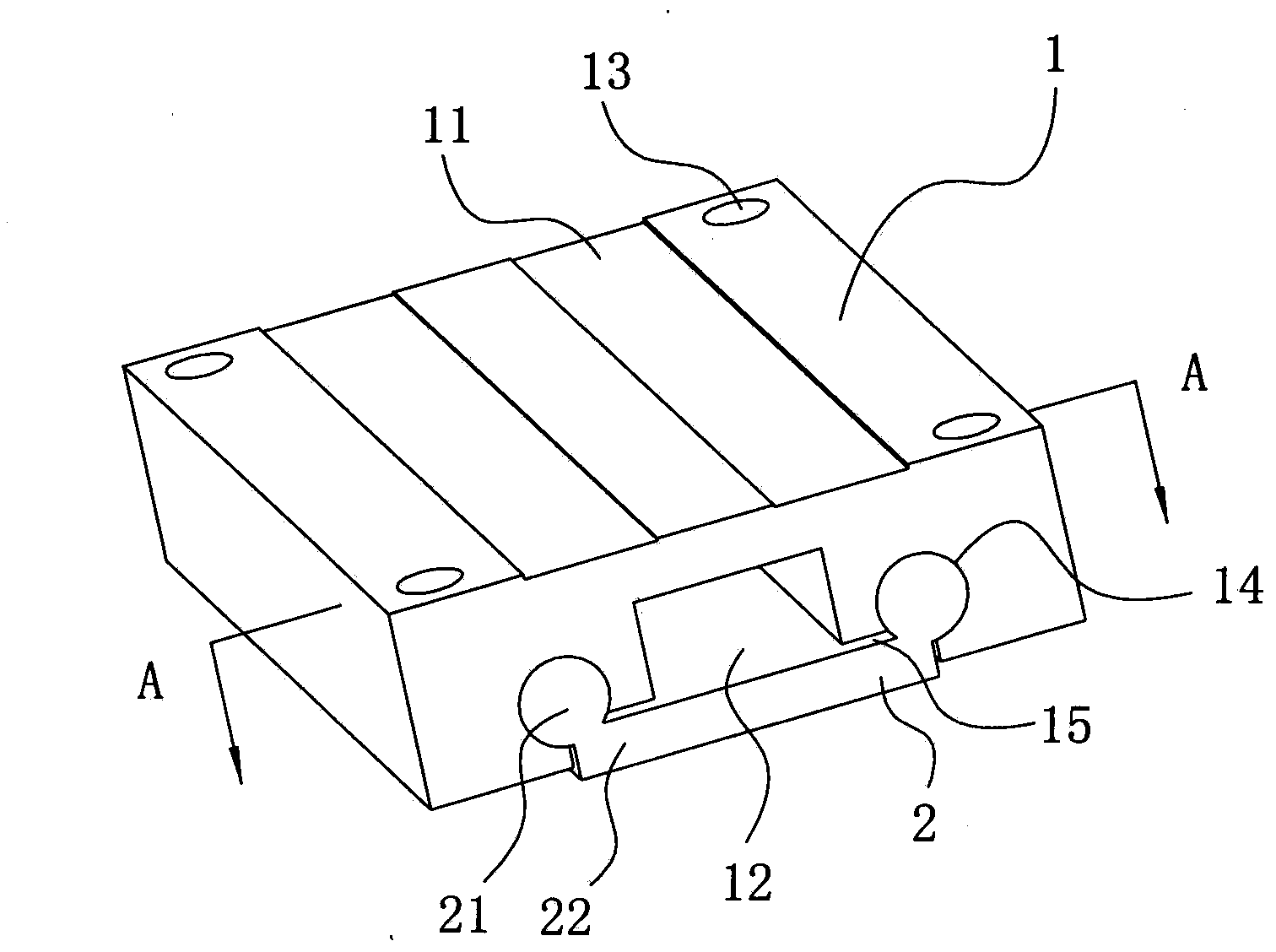

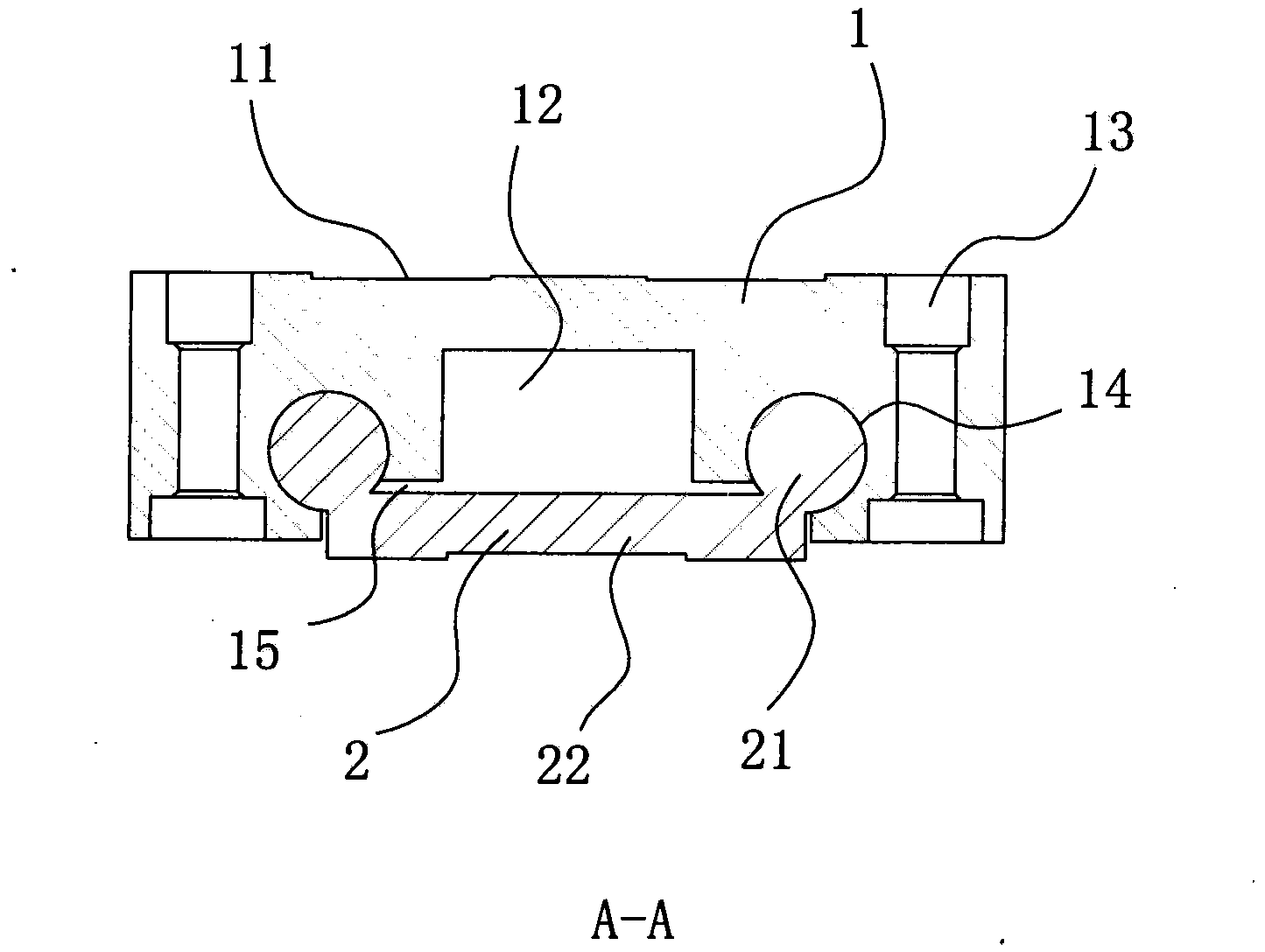

[0010] The specific embodiments of the present invention will be described below in conjunction with the drawings.

[0011] see figure 1 and figure 2 , The present invention includes a sliding seat 1 and a sliding body 2 that are slidably connected. The sliding seat 1 is a rectangular parallelepiped structure with a connecting hole 13. The upper surface of the sliding seat 1 has a mounting groove 11, and the lower surface has a sliding groove. The sliding groove includes The square chute 15 and the circular chute 14 are connected to each other. The circular chute 14 is symmetrically arranged on both sides of the square chute 15; the sliding body 2 includes a square slider 22 placed in the square chute 15. The square slider The two sides of 22 are symmetrically connected to the cylindrical sliding block 21, and the cylindrical sliding block 21 is placed in the circular sliding groove 14; the sliding seat 1 also has a square through hole 12 communicating with the square sliding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com