Electric ultrahigh-temperature butterfly valve

An ultra-high temperature, butterfly valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of low sealing performance of high temperature resistant butterfly valve, unsuitable use of high temperature medium, lower production efficiency, etc., to improve production efficiency and long service life. , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

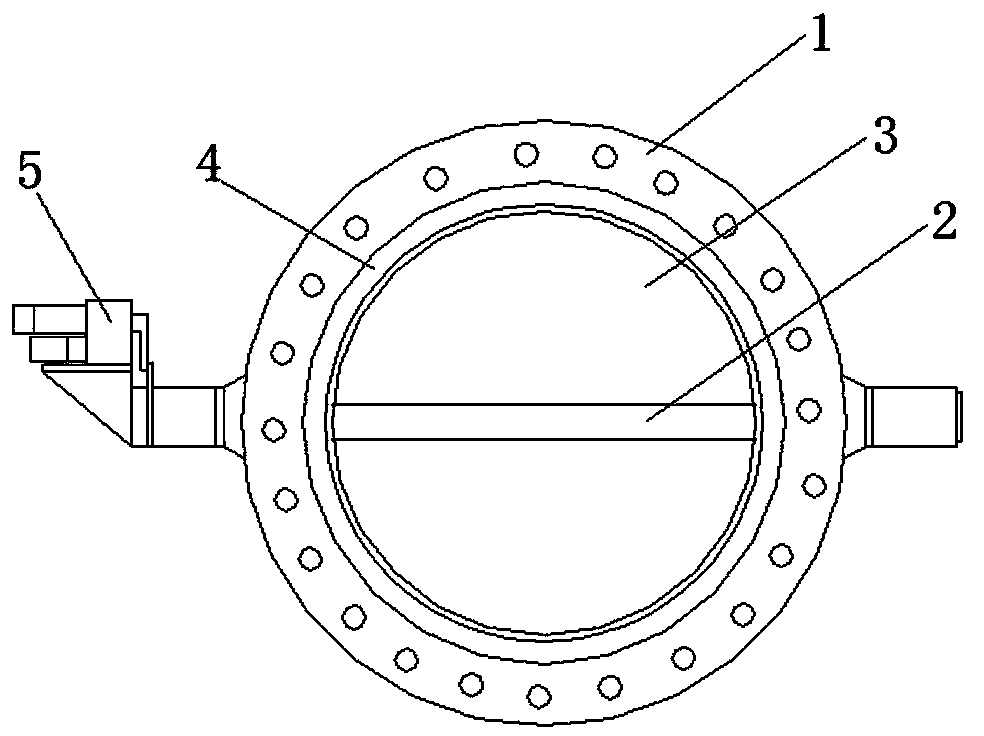

[0008] Such as figure 1 As shown, the electric ultra-high temperature butterfly valve includes a circular valve body 1, a valve shaft 2 and a butterfly plate 3 arranged in the circular valve body 1, the butterfly plate 3 rotates around the valve shaft 2, and the butterfly plate 3 A sealing ring 4 is provided between the circular valve body 1 , an electric actuator 5 is mounted on the outside of the circular valve body 1 , and the electric actuator 1 is connected to the end of the valve shaft 2 . Wherein, the ultra-high temperature butterfly valve is an alloy steel butterfly valve. In this embodiment, since the high-temperature butterfly valve is welded with alloy steel, it has the advantages of high temperature resistance, wear resistance, strong rigidity, small heat loss, and flexible operation. It can be installed horizontally or vertically. Realize automatic control operation. When in use, the electric actuator receives the control signal of the upper instrument such as tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com