Compressed air system of thermal power plant and its pressure graded supply method

A technology for thermal power plants and compressed air, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as increased energy consumption of compressed air system equipment, reduce operating power consumption, simple switching operations, The effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

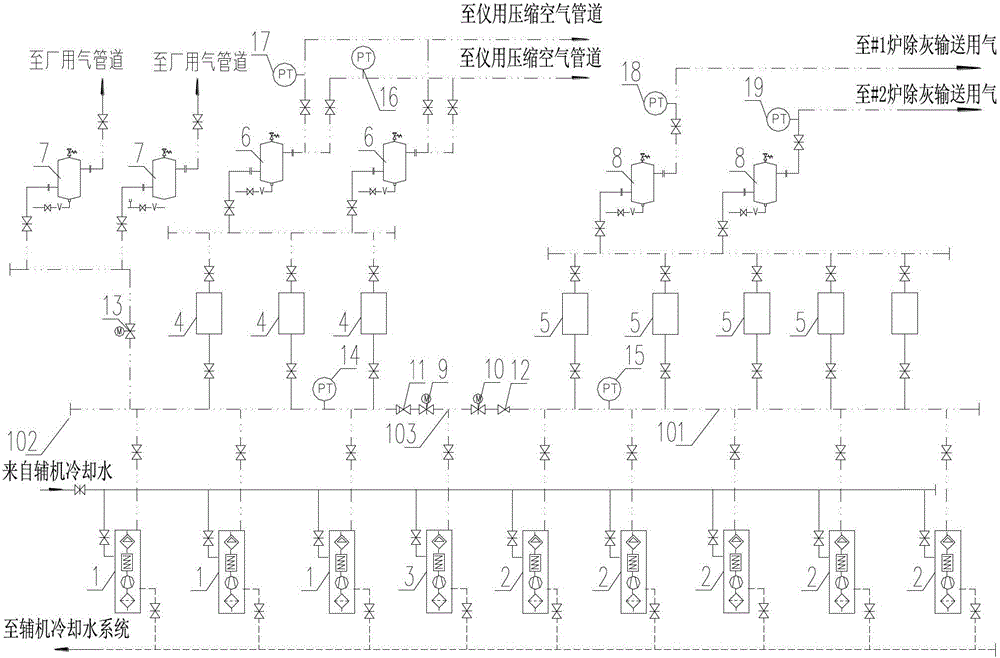

[0016] Such as figure 1 As shown, a kind of thermal power plant compressed air system of the present invention comprises 9 air compressors: 3 outlet pressure 0.75MPa~0.85MPa conventional instrument factory air compressors 1, 2 operation, 1 operation standby; 5 2 sets of low-pressure air compressors with an outlet pressure of 0.40MPa~0.50MPa for ash removal, 4 in operation, and 1 in standby; 1 outlet pressure of 0.75MPa~0.85MPa for routine maintenance and standby air compressor 3 as instrument factory air and removal A spare machine for public maintenance of gray gas. Post-processing equipment There are 3 sets of post-processing equipment 4 for instrumentation, 2 for operation and 1 for standby; 5 sets of post-processing equipment for ash removal 5, 4 for operation and 1 for standby. The gas storage tanks are equipped with 2 gas storage tanks 6 for instrumentation, 2 gas storage tanks 7 for factory use, and 2 gas storage tanks 8 for ash removal.

[0017] The outlets of the 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com