Heat supply system utilizing return water

A technology for heating systems and heating pipes, which is applied in heating systems, household heating, hot water central heating systems, etc., and can solve problems such as high operating costs, high engineering costs, and unreasonable operating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

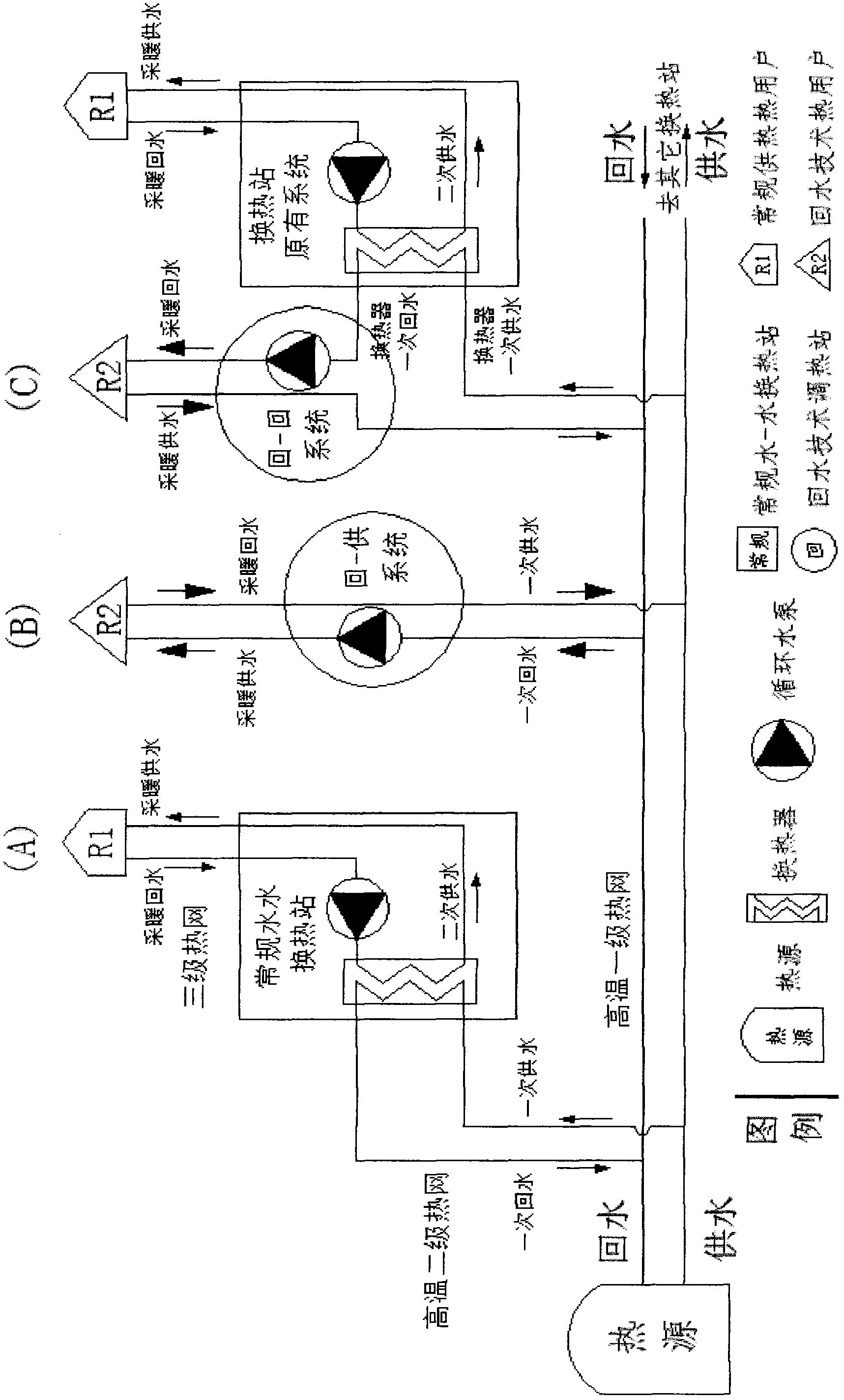

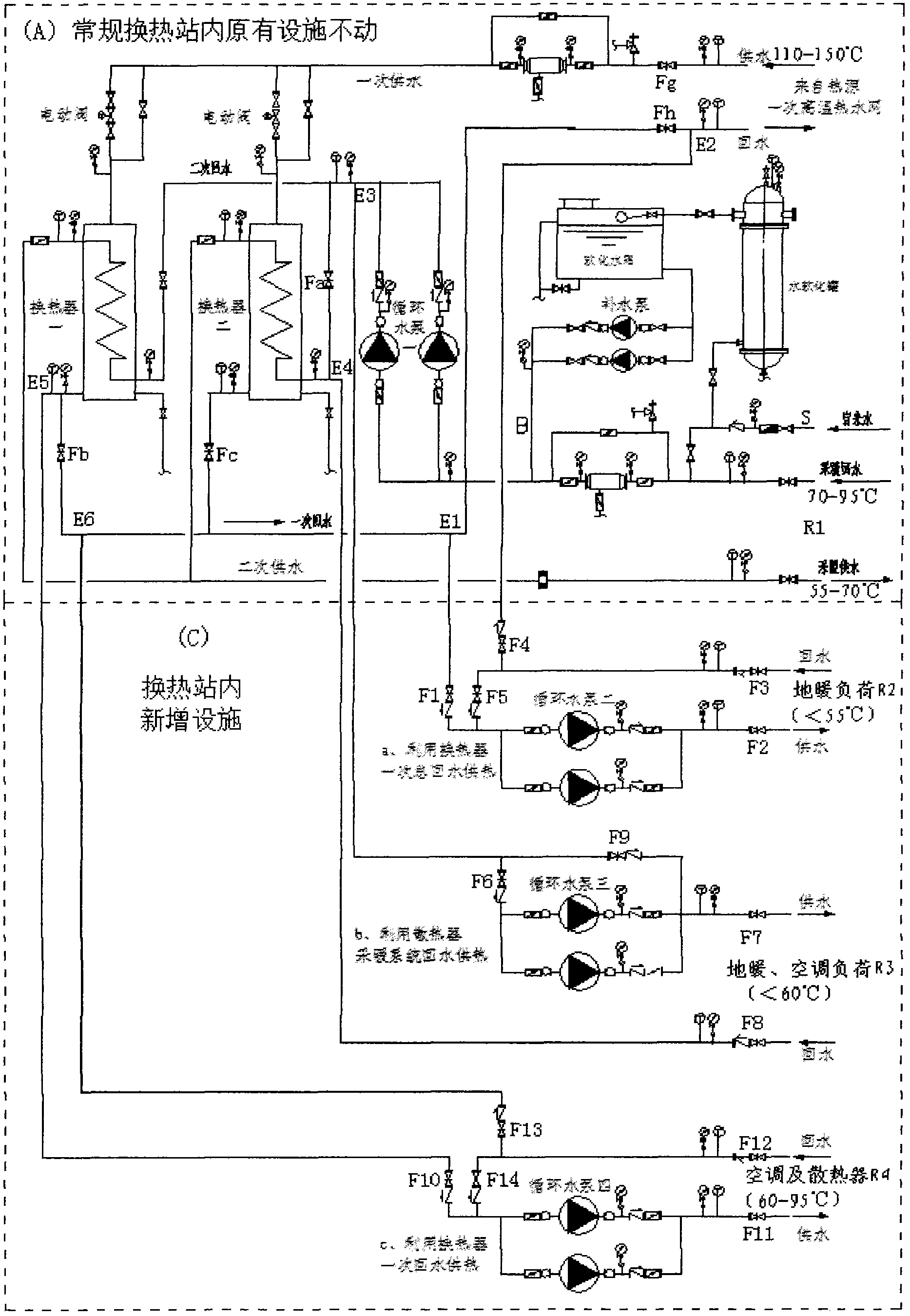

[0025] 1. Several configuration schemes of the backwater heating system

[0026] figure 1 It is the main system diagram of the return water heating system and the conventional water-to-water heat exchange at the same time.

[0027] 1, figure 1 The scheme (A) in the scheme is the heat supply system of a conventional water-water heat exchange station, and will not be repeated here.

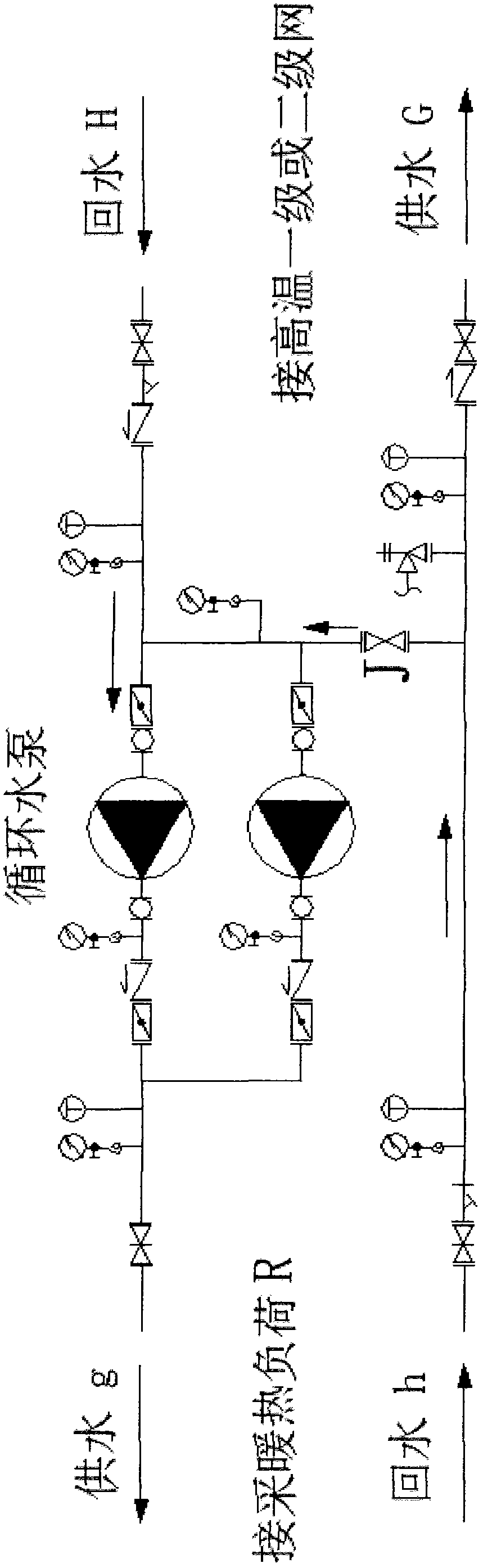

[0028] 2, figure 1 The (B) scheme is to use the return water of the high-temperature primary or secondary pipe network, and return the heating return water after heating to the "return-supply system" of the high-temperature network water supply system. figure 2 Yes - for detailed configuration of the system.

[0029] The working principle is as follows: the return water temperature of the high-temperature hot water network (or direct supply high-temperature hot water network) of water-to-water heat exchange is equivalent to the supply water temperature required by the heating system, so the ret...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap