Briquette drying method

A technology of briquette and drying furnace, which is applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of uneven distribution of hot air in drying furnace, low heat utilization rate, small heat loss, etc., and achieve a solution The effects of uneven coal discharge, high utilization rate of hot air, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

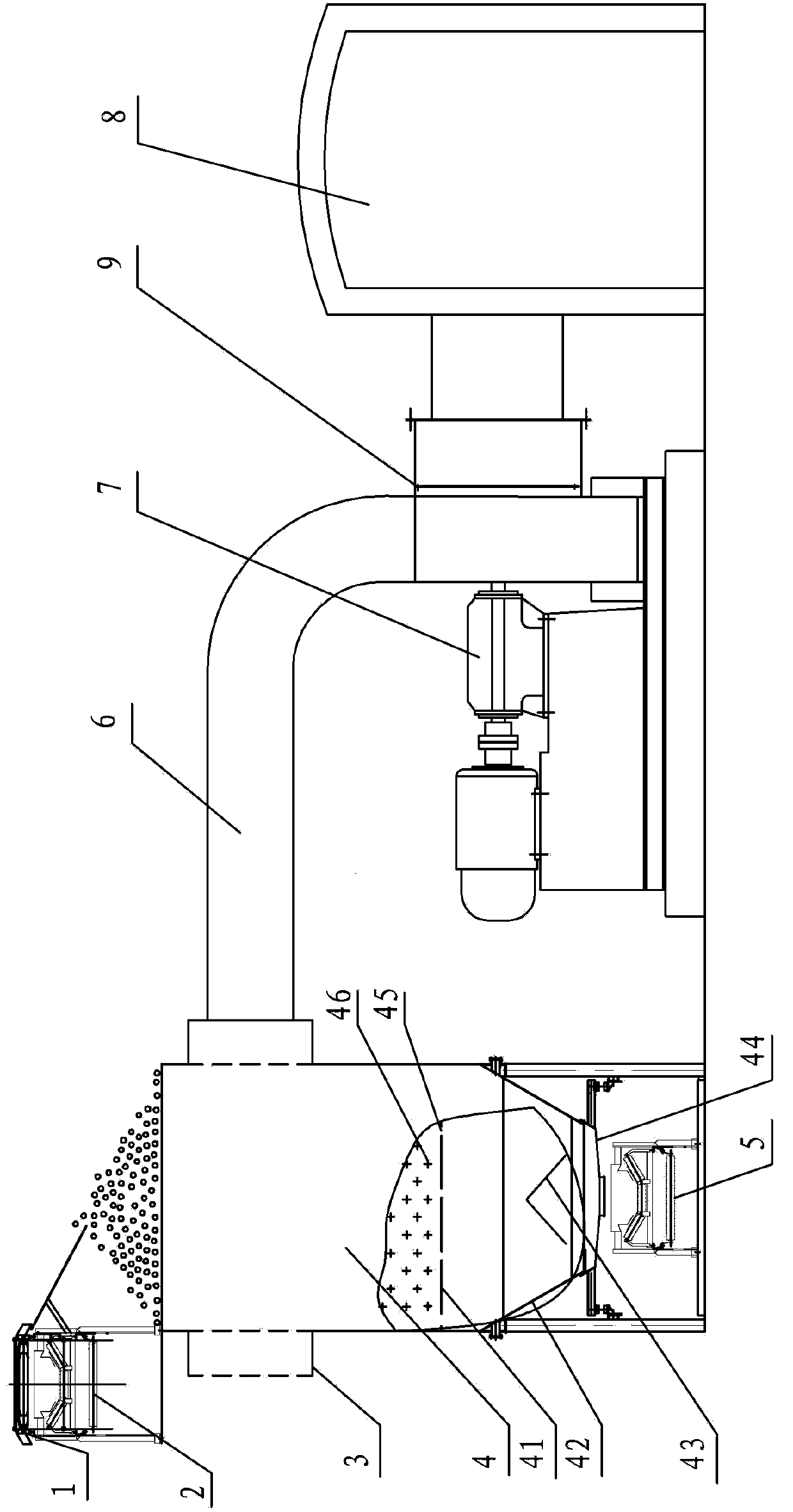

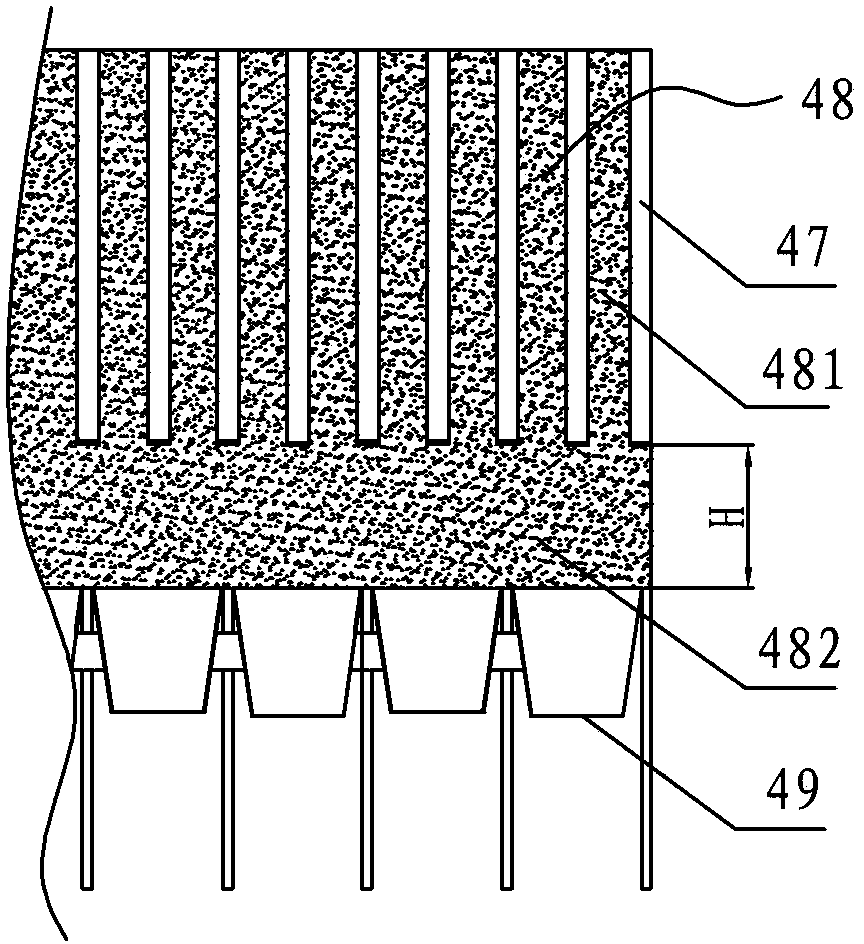

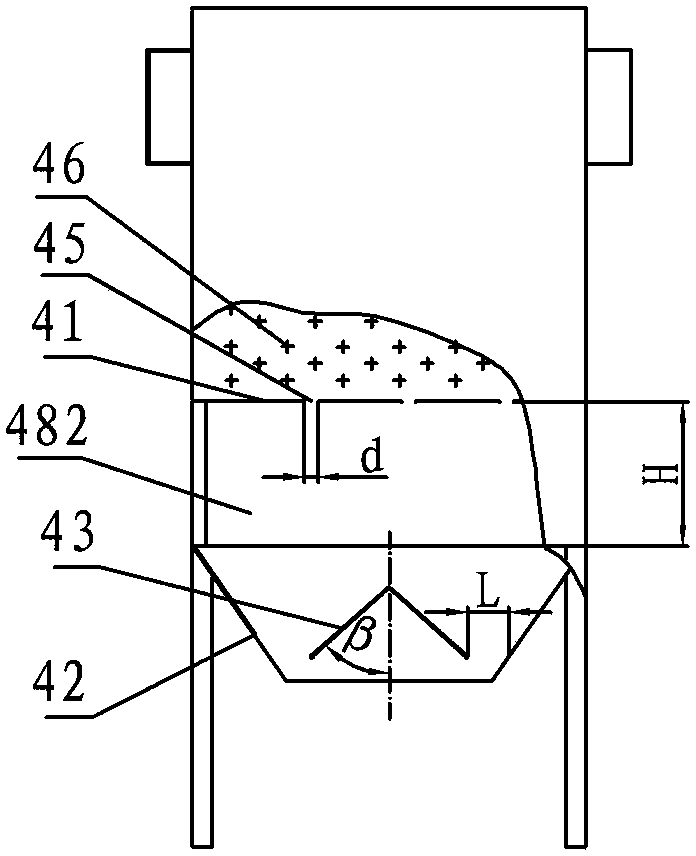

[0031] A method for drying coal briquettes, the steps of which are: sending the extruded coal rods to the top of the drying furnace 4 through the coal feeding belt 2, and evenly distributing the coal rods by the unloading trolley 1 on the coal feeding belt On the drying furnace 4, the drying furnace includes a body of furnace, a coal hopper 49 positioned at the bottom of the body of furnace, an air duct 47 and a coal duct 48 located in the body of the furnace, and the bottom of the air duct is provided with an ash discharge hole 45. The coal passage includes a longitudinal coal passage 481 and a transverse coal passage 482. The transverse coal passage is located at the bottom of the furnace body. The longitudinal coal passage and the air passage are arranged at intervals and located above the transverse coal passage. The longitudinal coal passage It is connected with the horizontal coal passage, and the air passage is connected with the horizontal coal passage through the ash d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com