A lag angle precision detection device capable of adjusting feeder height

A technology of a height adjustment device and a detection device, which is applied in the field of optical fiber precision winding, and can solve problems such as the inability to meet the requirements of optical fiber precision wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

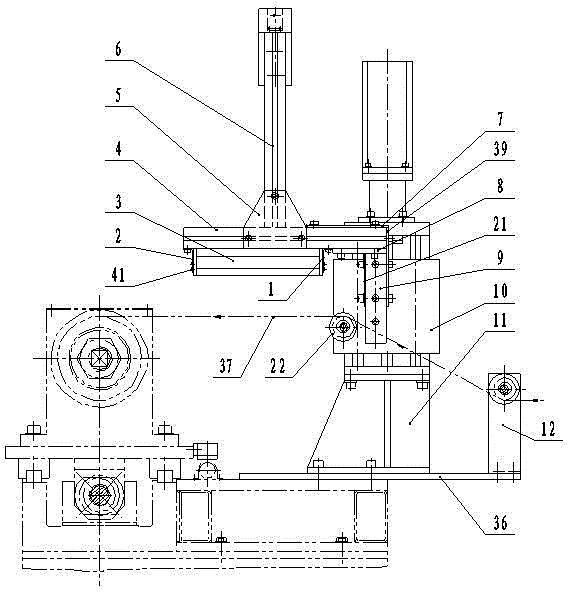

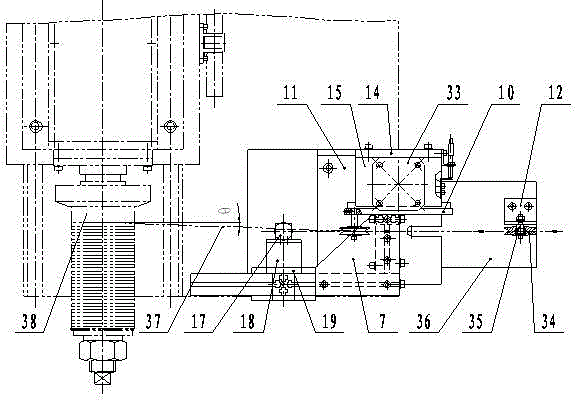

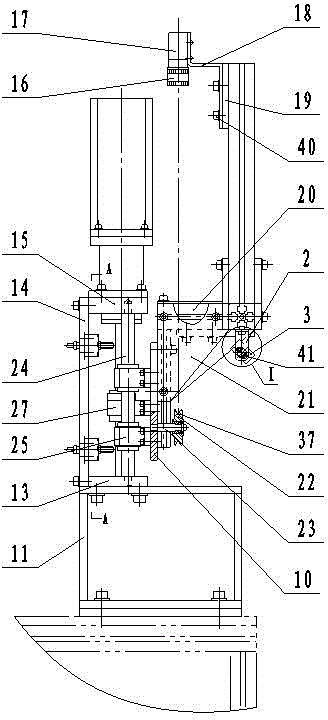

[0025] exist figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the specific embodiment of the present invention includes a delay angle precision detection device and a feeder height adjustment device, and the lag angle precision detection device is installed on the front of the lifting plate (10) of the feeder height adjustment device;

[0026] exist figure 1 , figure 2 , image 3 and Figure 5 Among them, the lag angle precision detection device includes a frame body, a lens (16), an industrial CCD camera (17), a bracket (18), an adjustment pad (19), two adjustment screws 1 (40), and a bar light source (3) , light source bracket 1 (1), light source bracket 2 (2), 4 adjusting screws 2 (41); the frame body includes aluminum profile 1 (9), aluminum profile 2 (20), aluminum profile 3 (4) , aluminum profiles 4 (6), inner connecting plate (21), outer connecting plate (39), upper connecting plate (7), lower connecting plate (8) and 2 T-shaped connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com