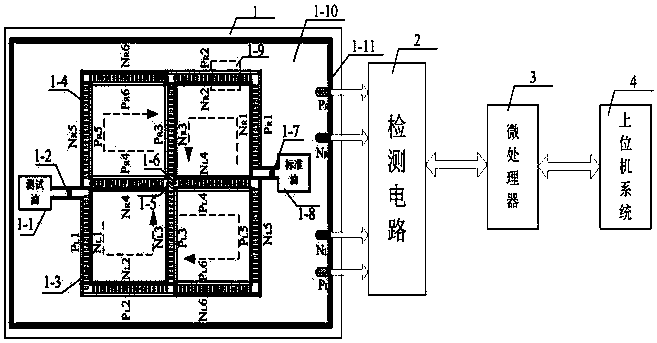

A microfluidic-based transformer oil micro-water detection system

A transformer oil and detection system technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of many consumables, narrow measurement voltage output range, small water detection range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

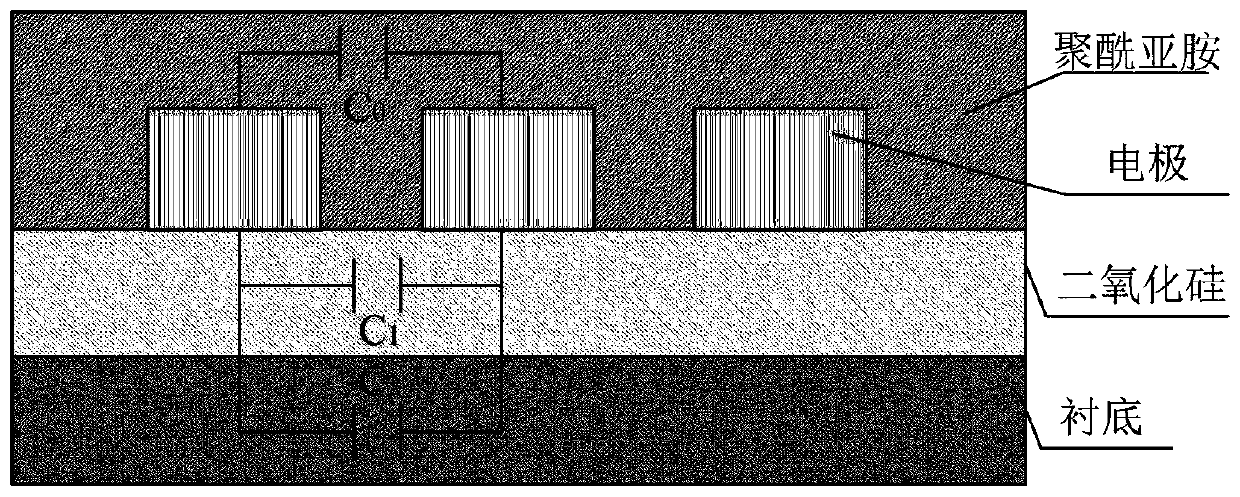

[0066] In this embodiment, the interdigital electrode structure model is taken as an example to describe the process of converting the water content in the test oil into the capacitance representation of the interdigital electrode. The manufacturing process of the microfluidic chip can be divided into eight steps, which are cleaning and oxidation of the silicon wafer substrate, sputtering of the lower electrode, coating of polyamic acid and imidization, sputtering of the upper electrode, etching and scribing, and corrosion. Upper electrode, etch the lead hole of the lower electrode, slice and press-weld the package. The cross-section of the interdigitated electrode structure is as follows image 3 As shown, the interdigital electrode capacitance can be equivalent to the ideal output capacitance C0 of the electric field line passing through the polyimide dielectric layer, the parasitic capacitance C1 of the electric field line passing through the silicon dioxide layer, and the ...

Embodiment 2

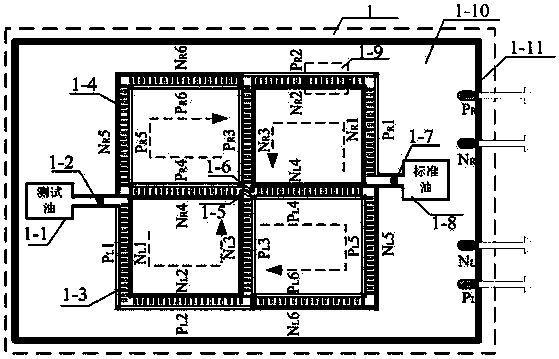

[0085] In this embodiment, the structure of the microfluidic chip is taken as an example to describe the process of transformer oil detection and water content model establishment based on the microfluidic chip.

[0086] Working mode one: open test oil injection valve 1-2 and standard oil injection valve 1-7, close test oil passage valve 1-5, standard oil passage valve 1-6. Test oil injection by P L1 N L1 —P L2 N L2 —P L3 N L3 constituted by the detection channel, the standard oil injected by P R1 N R1 —P R2 N R2 —P R3 N R3 In the test oil detection channel formed, the dimensions of the 12 interdigital positive electrodes and the 12 interdigital negative electrodes in the microfluidic chip of the present invention are consistent, so the standard oil equivalent capacitance as a reference capacitance in the detection system is expressed as:

[0087] C M1X1 =k 0 3n3lε 油 +C σ油M1 =9k 0 nlε 油 +C σ油M1 (9)

[0088] Similarly, the equivalent capacitance of the test ...

Embodiment 3

[0111] In this embodiment, the above-mentioned water content model and detection data are taken as examples to illustrate the numerical analysis of the detection results of transformer oil based on the microfluidic chip and the display of the upper computer. In the present invention, the sample stock solution of standard oil and measuring oil is injected at one time, and three measurement modes can be realized at one time according to the above sequence. By analyzing and comparing the measurement results obtained in the three modes, the " Various display methods and conclusions, such as "relative value of water content", "moisture content per unit volume", "warning curve of water content", are convenient for users to obtain the health status of transformer operation. In the actual detection, in order to further reduce the influence of parasitic capacitance and other environmental factors on the theoretical calculation results, a linear regression model was established for the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com