A detection device for a closed special-shaped curved groove on the inner wall of a high-precision cylindrical sleeve

A technology of detection device and cylindrical sleeve, which is applied in the direction of measurement device, electromagnetic measurement device, electric device, etc., can solve the problems such as no published discussion, and achieve the effect of satisfying high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

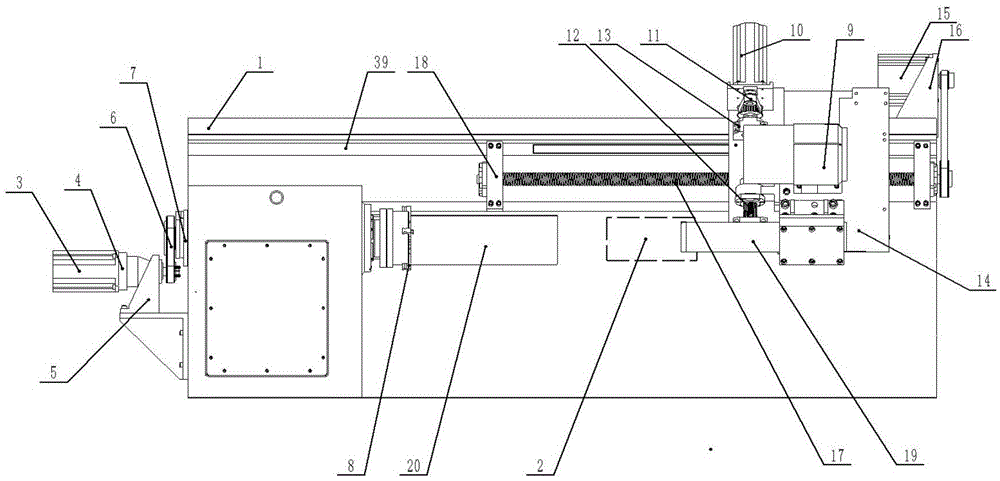

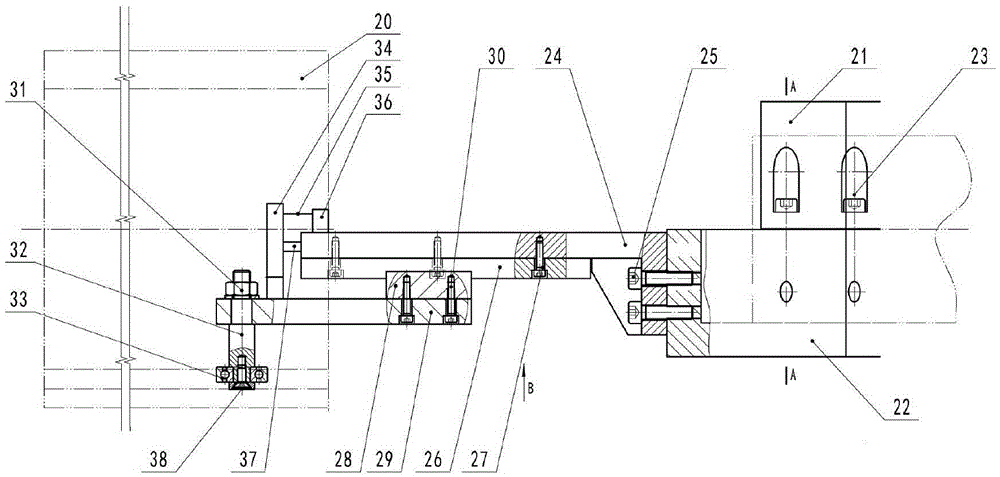

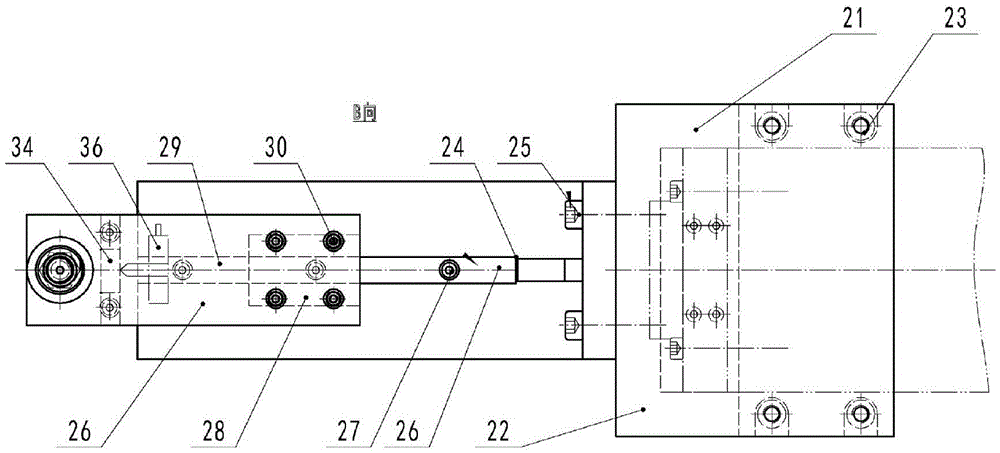

[0019] exist figure 1 Among them, the device includes a workpiece spindle transmission system, a bed (1), a depth feed shaft transmission system, a linear feed shaft transmission system, a detection device (2), a data acquisition feedback system, a numerical control system, and an inductance micrometer; The main shaft transmission system includes AC servo motor 1 (3), reducer (4), motor bracket (5), arc transmission belt (6), main shaft (7), four-jaw clamp (8); the workpiece main shaft transmission system is composed of AC Servo motor 1 (3), reducer (4) and arc transmission belt (6) drive the main shaft (7) to rotate; the depth feed shaft transmission system includes X-axis sliding table (9), AC servo motor 2 (10), joint The shaft device (11), precision ball screw 1 (12), bearing support 1 (13); the AC servo motor 2 (10) of the depth feed shaft transmission system is installed on the Z-axis slide table (14), and drives the X The shaft slide table (9) moves up and down to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com