Active infrared tube defect detection method based on electromagnetic induction heating

A technology of electromagnetic induction heating and infrared detection, which is applied in the direction of induction heating, material defect testing, induction heating devices, etc., to achieve the effects of low cost, uniform heating and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

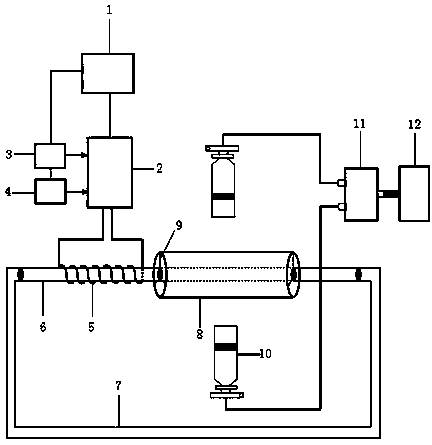

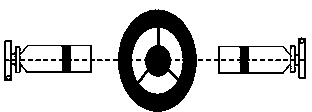

[0008] Such as figure 1 As shown, the present invention is realized in this way, the AC power supply 1 is connected to the frequency converter 2 to make it change from low frequency to high frequency; the control circuit 3 is connected to the frequency converter 2 to play the role of switching circuit and automatic inspection, and protect the circuit 4 is connected with the frequency converter 2 to play the role of maximum current limit, over or under voltage protection. The stranded enameled wire 5 is evenly wound on one end of the ferromagnetic rod 6 as a coil, and the other end of the ferromagnetic rod 6 passes through the metal tube 8 and is fixed on the central axis of the metal tube 8 with a high-temperature-resistant plastic non-magnetic insulating material 9 Above, use the ferromagnetic clamp 7 to clamp the exposed ends of the ferromagnetic rod 6 to form a closed magnetic yoke. The two interfaces of the twisted enameled wire 5 are connected with the high-frequency ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com