End-prefabricated tightened fiber core butterfly guiding-in optical cable and implementation method thereof

A technology for introducing optical cables and fiber cores, applied in the direction of fiber mechanical structure, etc., it can solve the problems of not considering the prestress of outer sheath and fiber core, the influence of optical performance, and increase the cost of use, so as to achieve good tensile effect and reduce transmission loss. , The effect of reducing the problem of fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

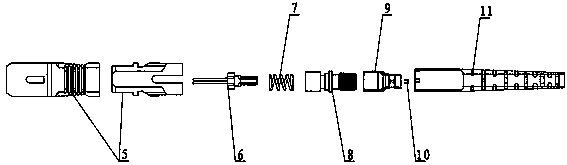

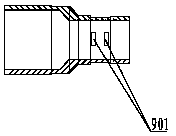

[0026] As shown in the figure, a prefabricated tight-buffered fiber-core butterfly lead-in cable includes a ceramic ferrule 6 located at the front end of the fiber optic speeder, connector parts and a tight-buffered fiber-core butterfly lead connected to the ceramic ferrule 6 fiber optic cable.

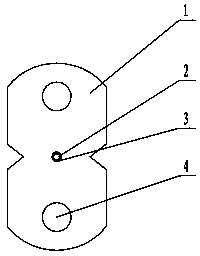

[0027] The tight-buffered fiber-core butterfly lead-in cable includes an outer sheath 1, a non-metallic strength member 4 symmetrically arranged in the outer sheath 1, and a colored optical fiber 2 arranged in the center of the outer sheath 1, and a protective sheath 3 is provided outside the colored optical fiber 2. As a preferred structure, the protective sheath 3 is a PVC sheath, the diameter of the protective sheath 3 is 0.6-0.9mm, and the thickness of the protective sheath 3 is 0.05-0.3mm.

[0028] Connector spare parts include fixing sleeve 5, spring 7, strengthening me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com