Die head of rubber cable production line

A rubber cable and production line technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve the problems of production efficiency, reduce equipment investment, meet diversity requirements, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

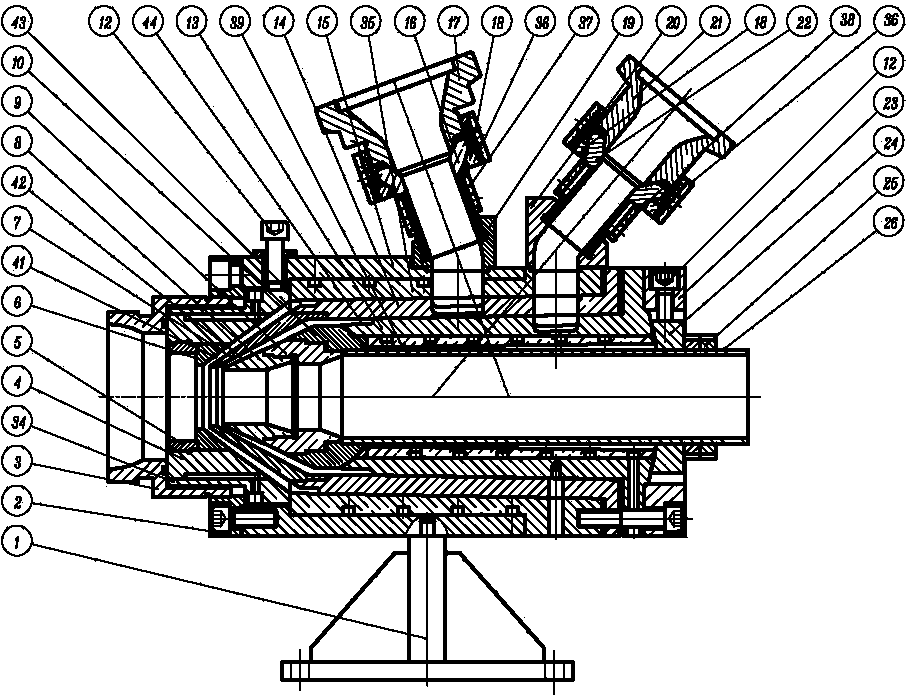

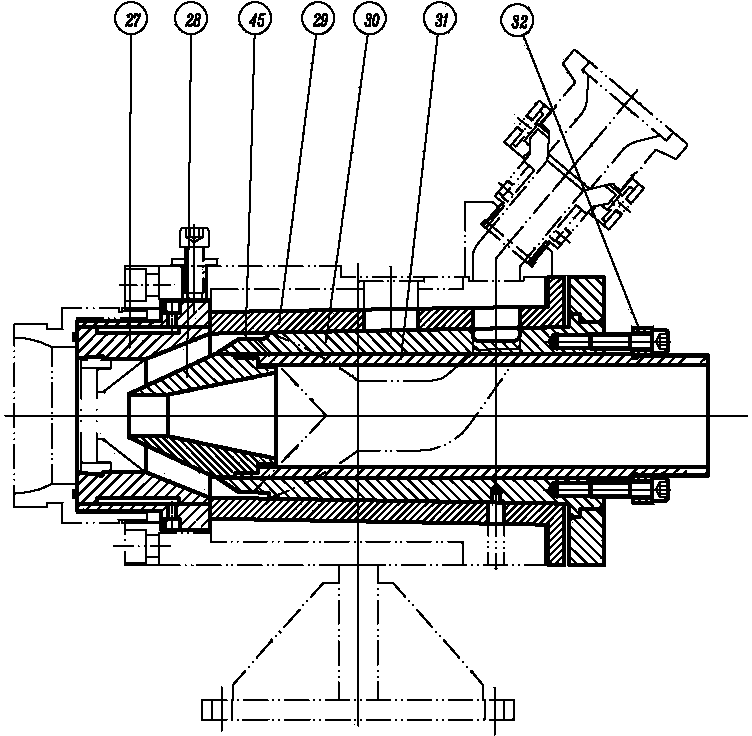

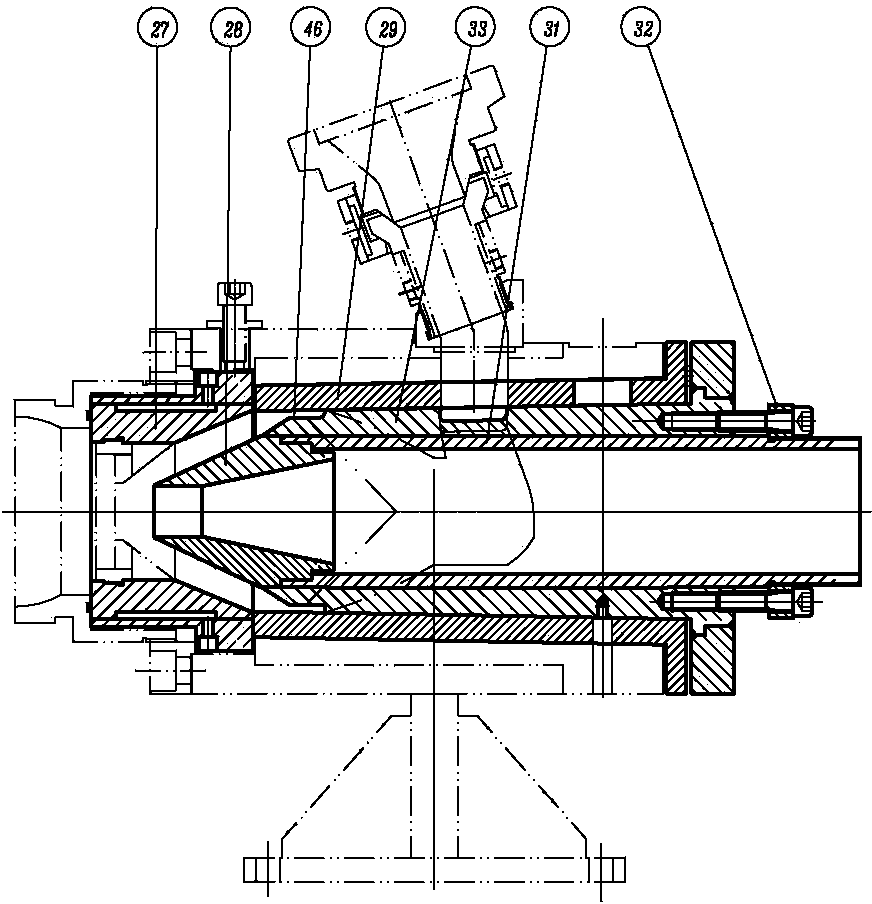

[0030] Such as figure 1 Shown is the double-layer coextruded state of the present invention. It includes a bracket 1 and a die body 15 installed on the bracket, a co-extrusion conduit 26 runs through the cavity of the die body, and a fluid separation unit with a combined fluid separation structure is provided between the die body and the conduit. The split body unit includes an insulating split body 13 and an outer shield split body 14 which are stacked. Wherein the insulating shunt body 13 is located inside, adjacent to the co-extruded wire tube 26 . The outer screen divider body 14 is located on the outside, adjacent to the die body 15 . The tail end of the insulating shunt body 13 is provided with a spherical shunt body seat 24 and a joint cap 25 for pressing. A deflection adjustment ring 23 against the insulating shunt 13 is also installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com