High-reliability LED (light emitting diode) bracket and LED device thereof

A technology for LED brackets and LED devices, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of water vapor or red ink setting effective obstacles, air tightness can not meet production requirements, reliability needs to be improved, etc., to achieve enhanced integration force, prolong the moisture penetration path, and improve the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

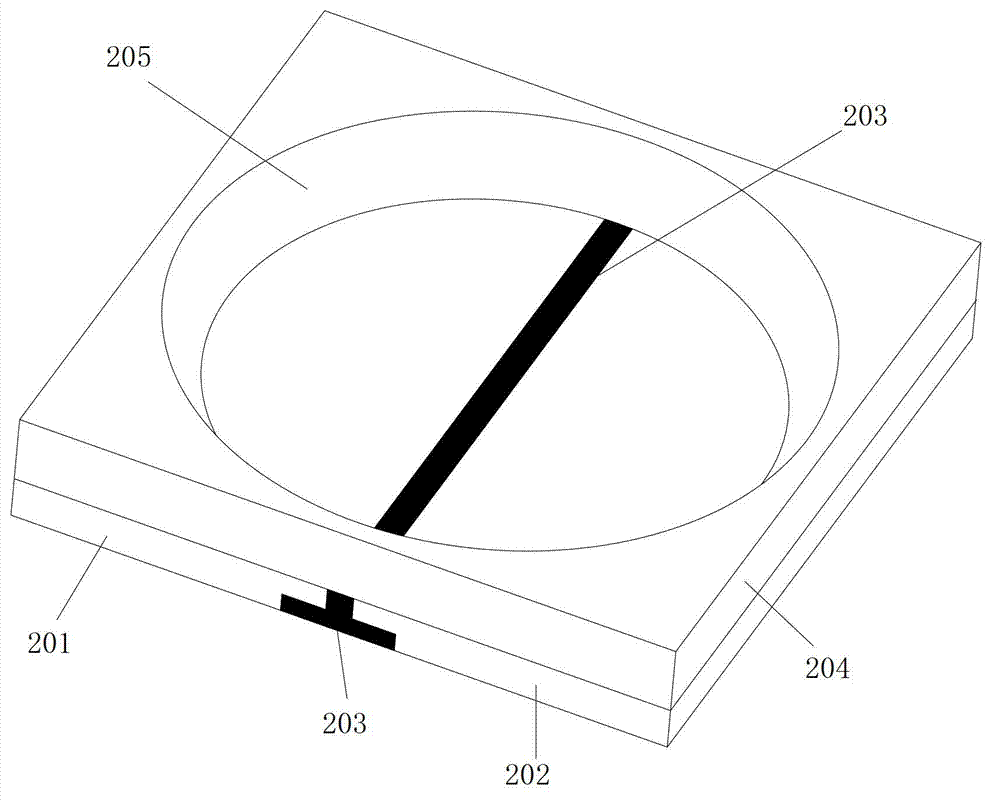

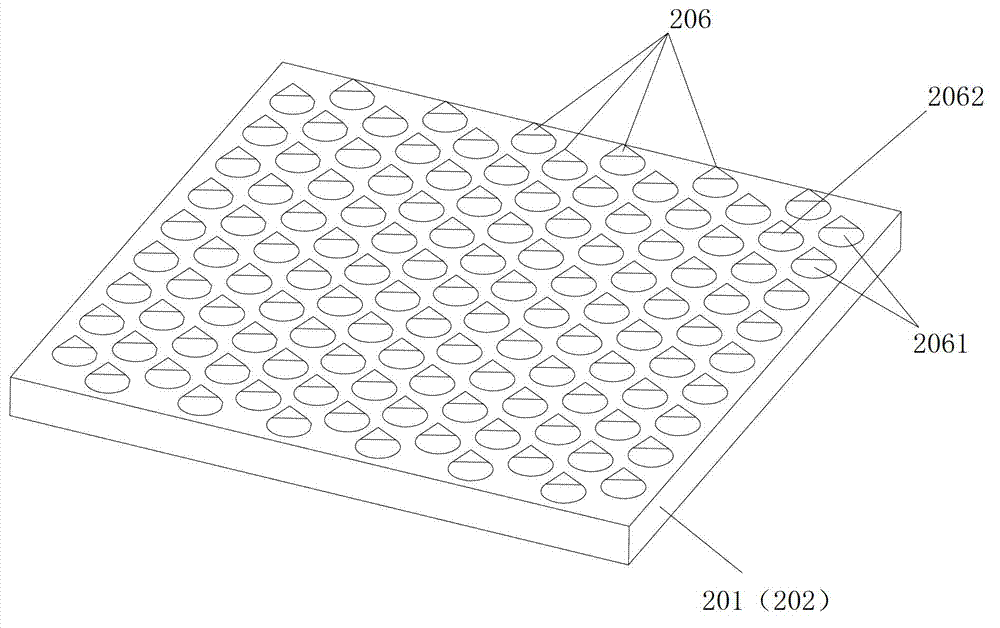

[0043] Such as figure 2 As shown, this embodiment discloses a high-reliability LED bracket, which includes a first pad 201 and a second pad 202 as conductive pins, and the first pad 201 and the second pad 202 pass through The insulating connecting colloid 203 is connected together, and an insulating seat 204 integrally formed with the connecting colloid 203 is also provided on the upper surface of the first pad 201 and the second pad 202, and an insulating seat 204 is formed inside the insulating seat 204. LED chips and reflective cups 205 for reflecting LED light are installed. Wherein, the first welding pad 201 and the second welding pad 202 are connected together through the connecting glue 203 integrally formed with the insulating seat 204, so that the firmness between the insulating seat 204 and the welding pads (201, 202) is strengthened. Not only that, in this embodiment, the unit protrusion structure 206 is provided on the upper surface of the first pad 201 and the s...

Embodiment 2

[0049] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is only that: the convex structure of the unit is changed from a conical shape to a prismatic shape. Compared with the conical structure, the prismatic structure makes the contact area between the two larger, so the bonding force is stronger. The path of moisture intrusion is further extended, and the reliability is better.

Embodiment 3

[0051] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is only that the raised structure of the unit is changed from a conical shape to a hemispherical shape. In this embodiment, the outer surface of the raised hemispherical structure presents a smooth curve shape, which greatly reduces the The stress on the bonding surface of 204 and the metal pad, under normal circumstances, the sharp corner is the stress concentration point, which is prone to the risk of microcracks and glue cracks caused by stress concentration, so the reliability of the bracket in this embodiment is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com