Lead-acid battery anode and lead-acid battery

A technology of lead-acid battery and negative electrode, which is applied in the direction of lead-acid battery electrode, lead-acid battery, lead-acid battery construction, etc. It can solve the problems of sudden death of the negative electrode ear and the expected arrival of life, and achieve the internal protection against rolling up and adhesion short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Hereinafter, the effects of the present embodiment will be described with reference to examples.

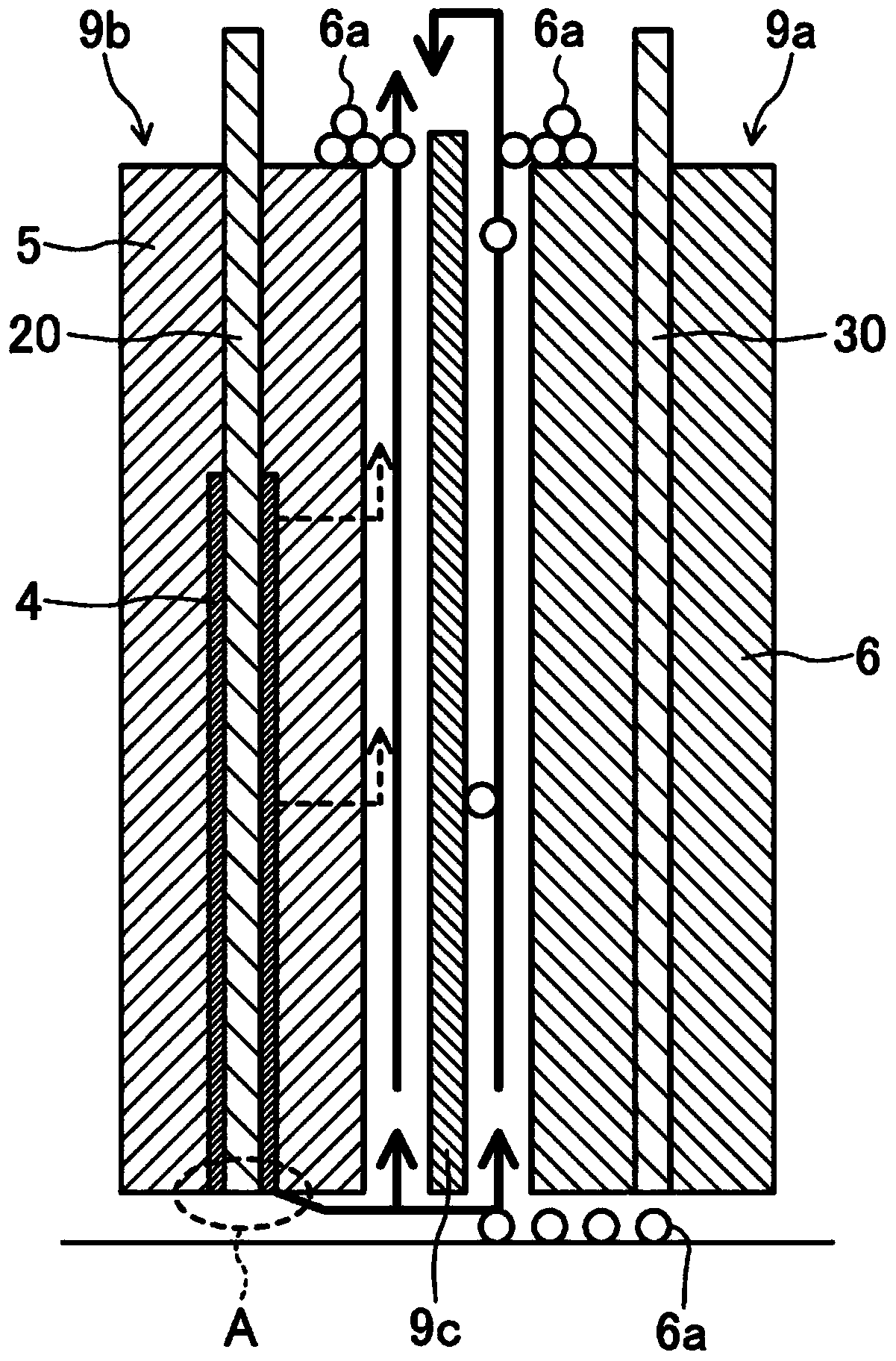

[0046] The lead oxide powder is kneaded with sulfuric acid and purified water to prepare a positive electrode active material paste. A positive electrode 9a was produced in the positive electrode grid 30 obtained by spreading out the calcium alloy.

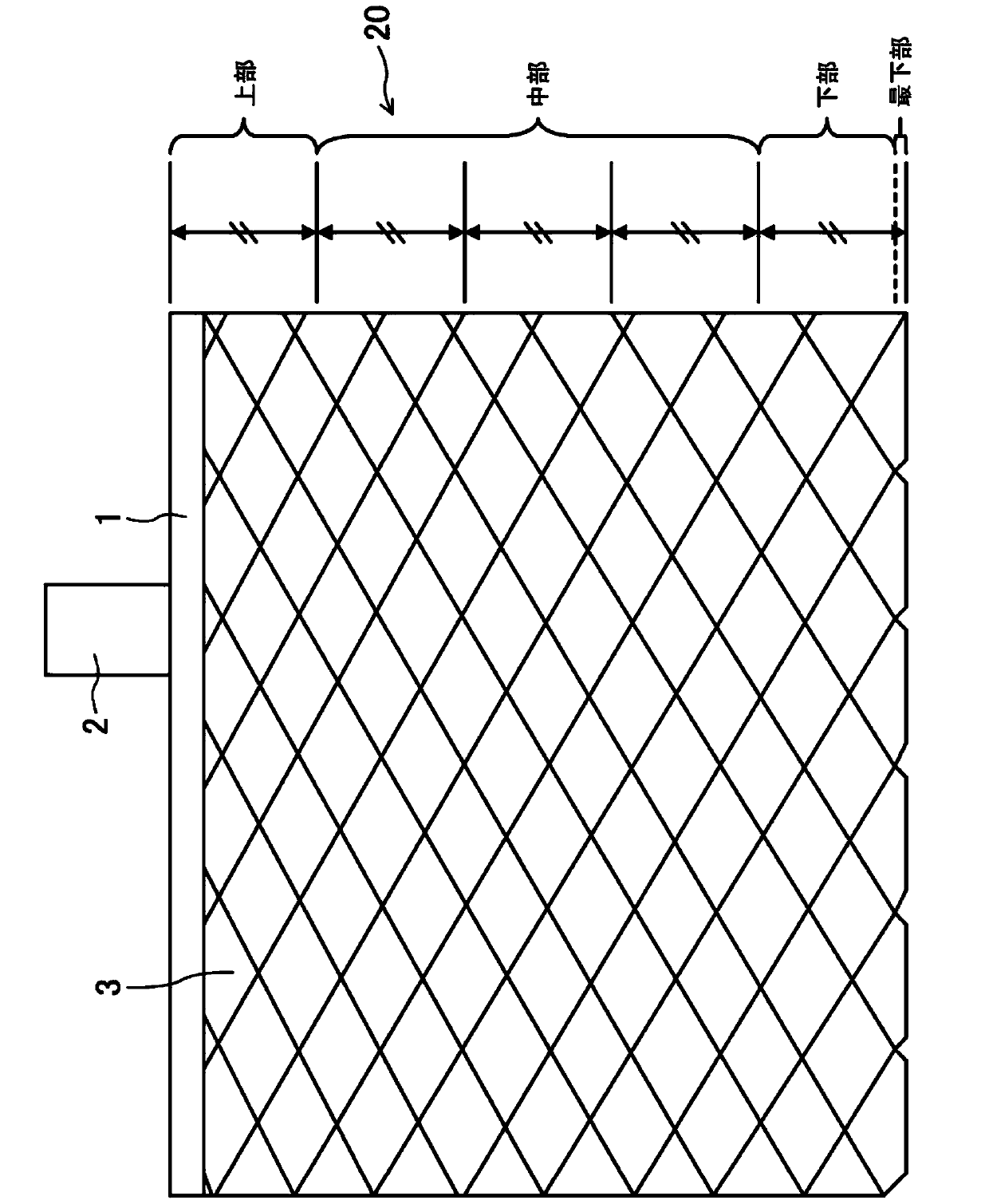

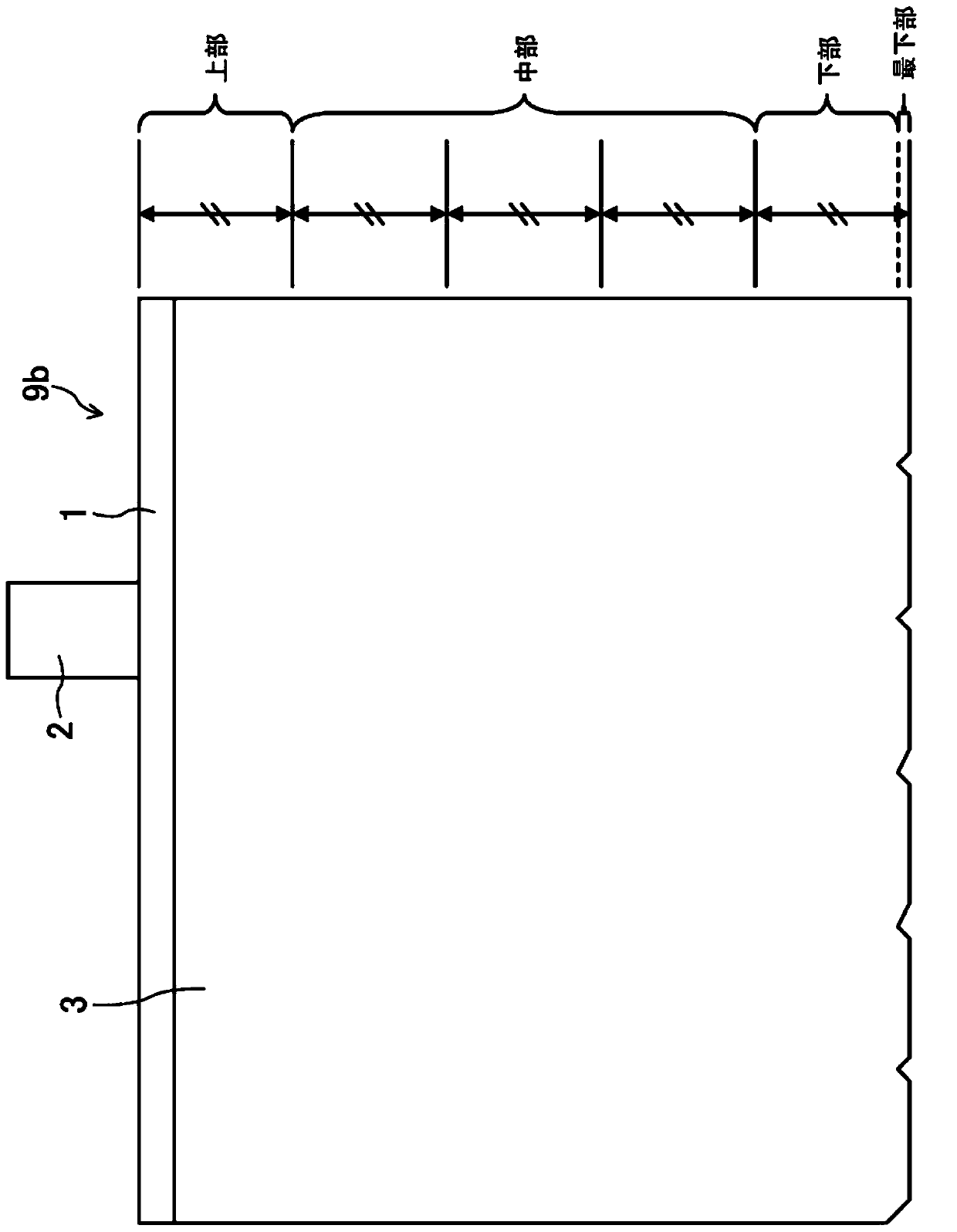

[0047] On the other hand, organic additives, barium sulfate, carbon, etc. are added to lead oxide powder by a conventional method, mixed with sulfuric acid and purified water to prepare a negative electrode active material paste, and the active material paste is filled in a reciprocating method. The negative electrode grid 20 obtained by stretching a rolled sheet (the composition is a lead-tin-calcium alloy) with the alloy layer 4 made of lead-tin-antimony on the surface under various conditions (the details will be described later) Among them, the negative electrode 9b (length 115 mm) was produced. The rolled sheet does not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap