Upper guide rail of agricultural machine

A technology for agricultural machinery and guide rails, which is applied in the field of upper guide rails, and can solve problems such as complex structures, chain jams, and scrapped bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

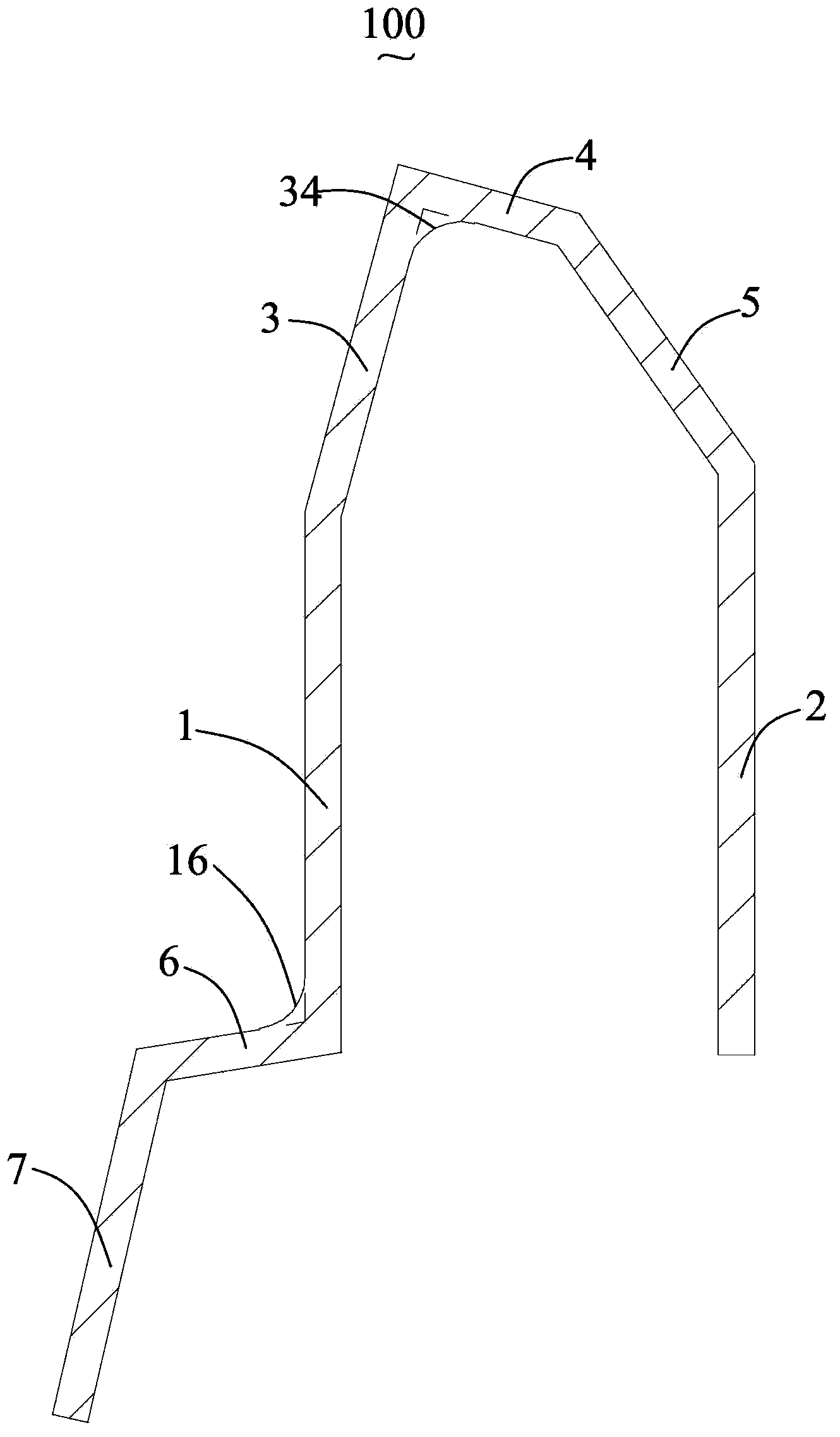

[0026] Such as figure 1 Shown is an upper guide rail 100 of an agricultural machine according to the present invention.

[0027] The upper guide rail 100 of the agricultural machine comprises: a first vertical bar 1 and a second vertical bar 2 arranged vertically, a third inclined bar 3 located between the first vertical bar 1 and the second vertical bar 2, The fourth slanting bar 4 , the fifth slanting bar 5 , and the sixth slanting bar 6 and the seventh slanting bar 7 connected to the first vertical bar 1 and extending outward. The first vertical rod 1 is parallel to the second vertical rod 2, and the surface of the first vertical rod 1 and the second vertical rod 2 is sprayed with sulfuric acid anodic oxidation layer, so the first vertical rod of the upper guide rail 100 1 and the second vertical rod 2 are less susceptible to external corrosion.

[0028] The third slanting bar 3 is connected to the first slanting bar 1, the fifth slanting bar 5 is connected to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com