Overground vertical type compressed garbage transfer station

A garbage transfer station, vertical technology, applied in the direction of garbage conveying, garbage collection, loading/unloading, etc., to achieve the effect of easy cleaning and improving the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

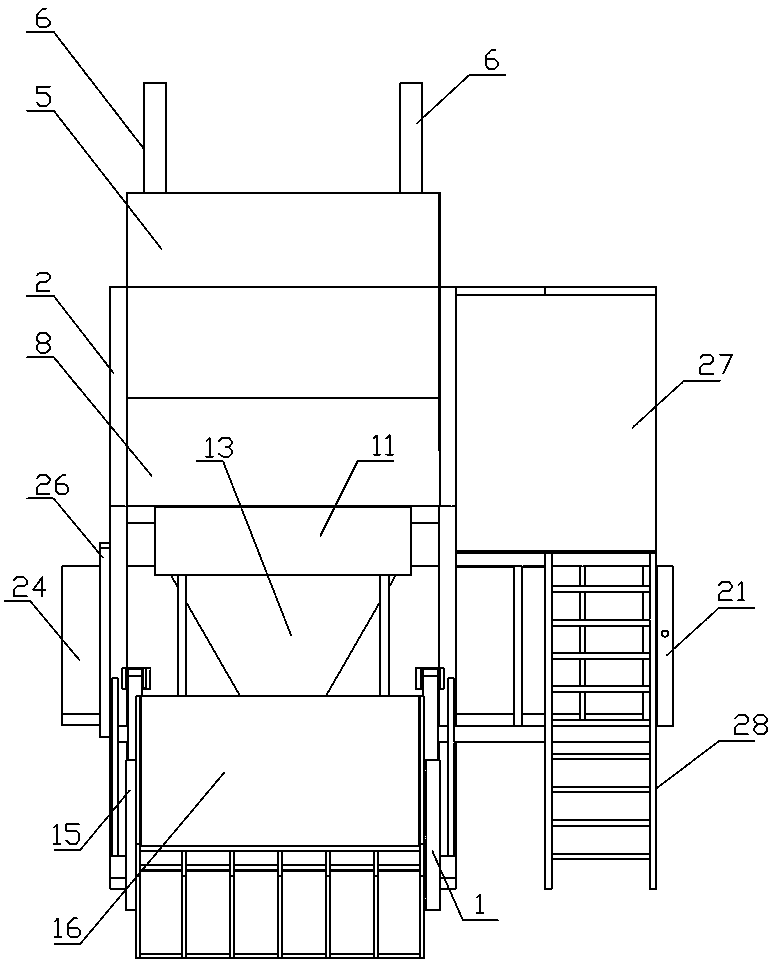

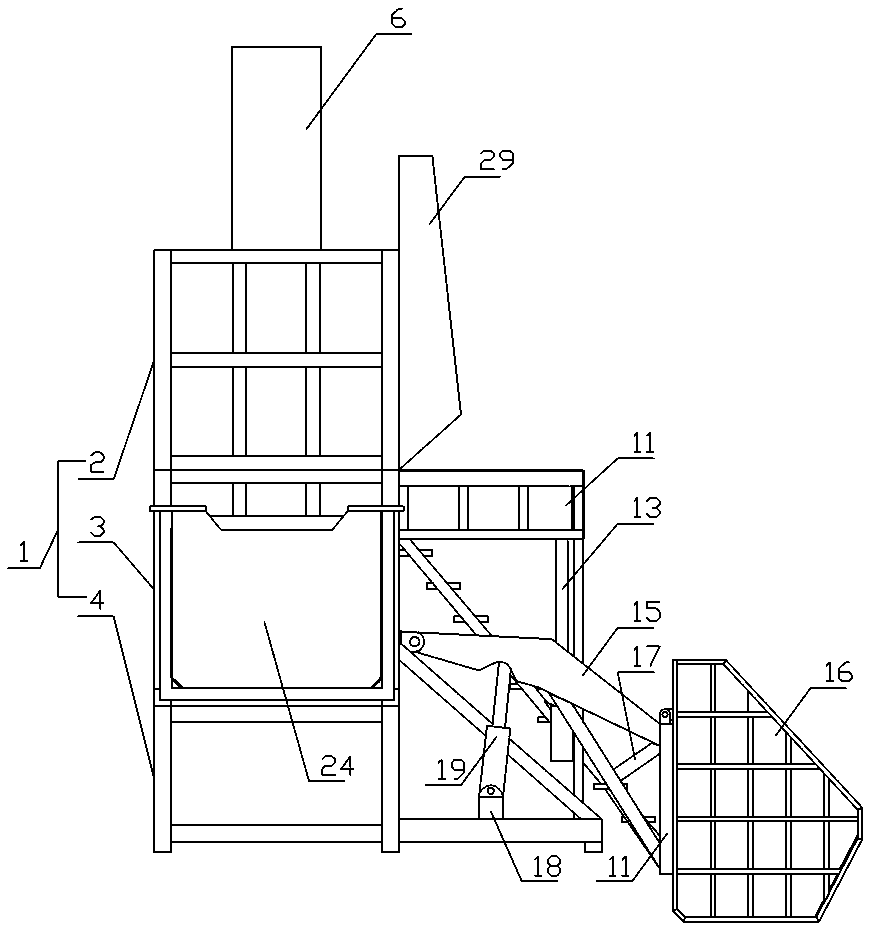

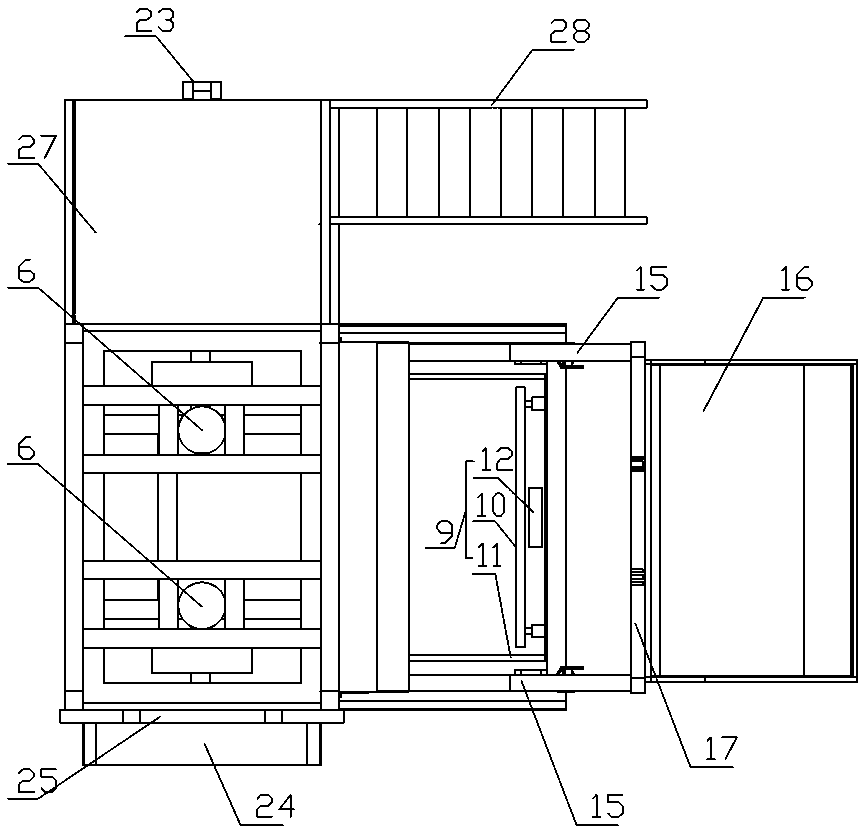

[0019] In this embodiment, a ground vertical compressed garbage transfer station has a vertical box 1, and the vertical box 1 sequentially includes a compression box 2, a storage box 3 and a support box 4 from top to bottom, wherein the compression The box body 2 and the storage box body 3 communicate with each other up and down, and a vertical hydraulic device 5 that can be extended into the storage box body 3 is installed above the compression box body 2. The vertical hydraulic device 5 includes four symmetrically arranged A vertical oil cylinder 6, the lower end of the vertical oil cylinder 6 is connected with a compression top plate 7, and when the vertical oil cylinder 6 is promoted, the compression top plate 7 can extend downward into the storage box 3 inside.

[0020] In this embodiment, there is a feeding port 8 on one side of the compression box 7, and an anti-spill funnel 29 is installed on the feeding port 8. The compression box 7 is also provided with a flattening m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com