Scallion harvest machine

A technology of harvester and shallots, which is applied to harvesters, excavators, excavators, etc., can solve the problems of high labor intensity and low production efficiency, and achieves reduction of labor intensity, production cost, and harvesting improvement. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

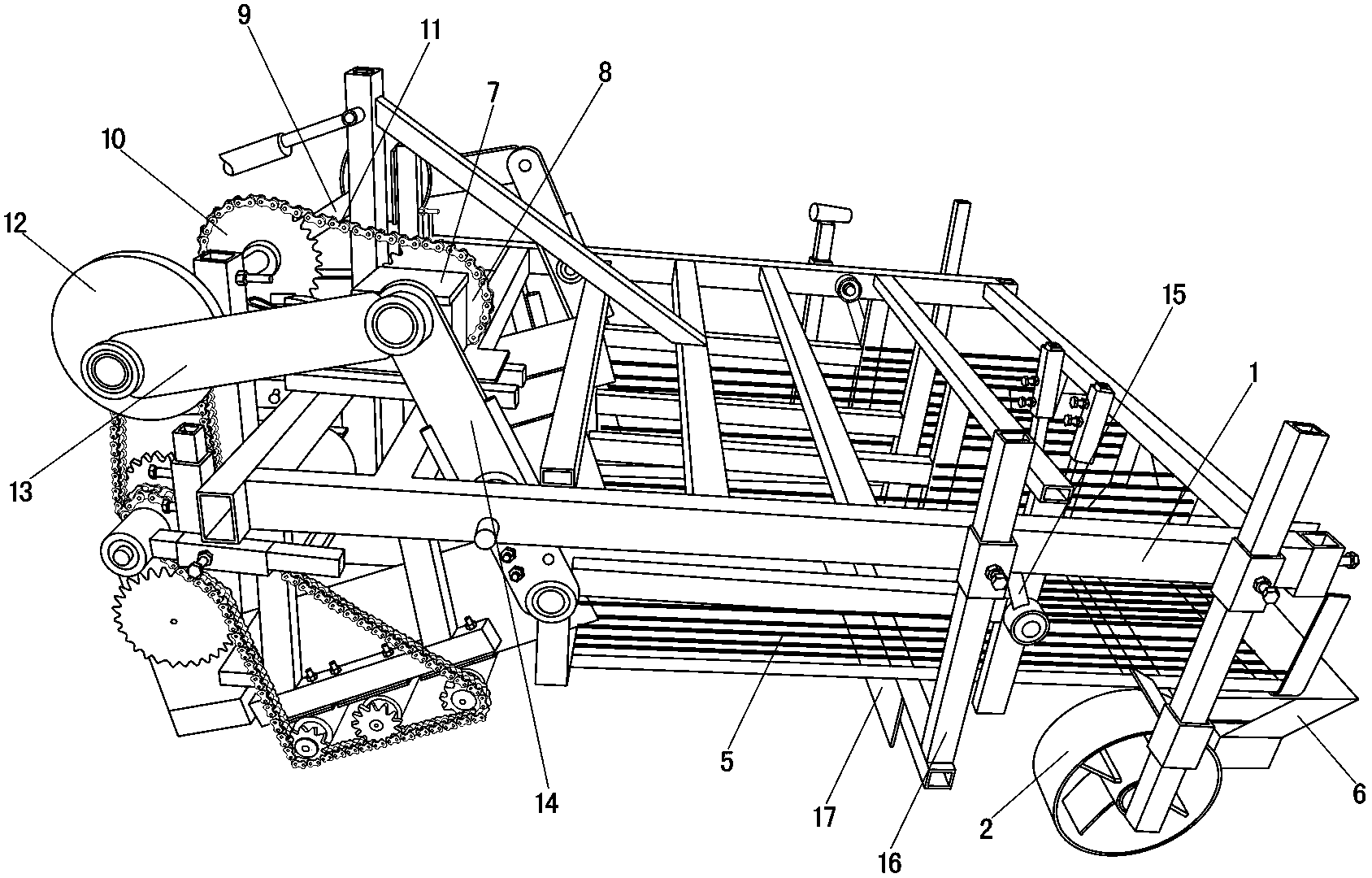

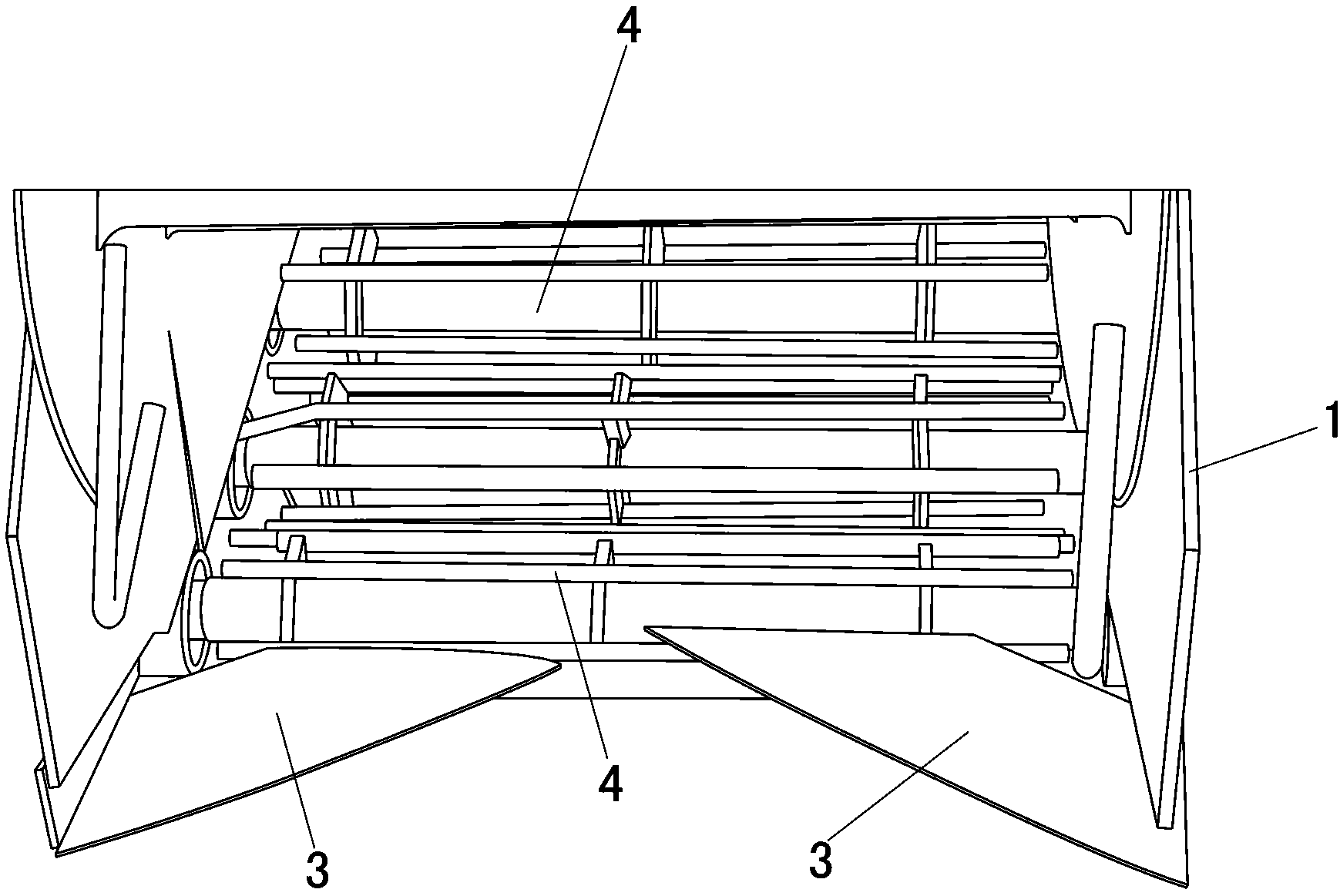

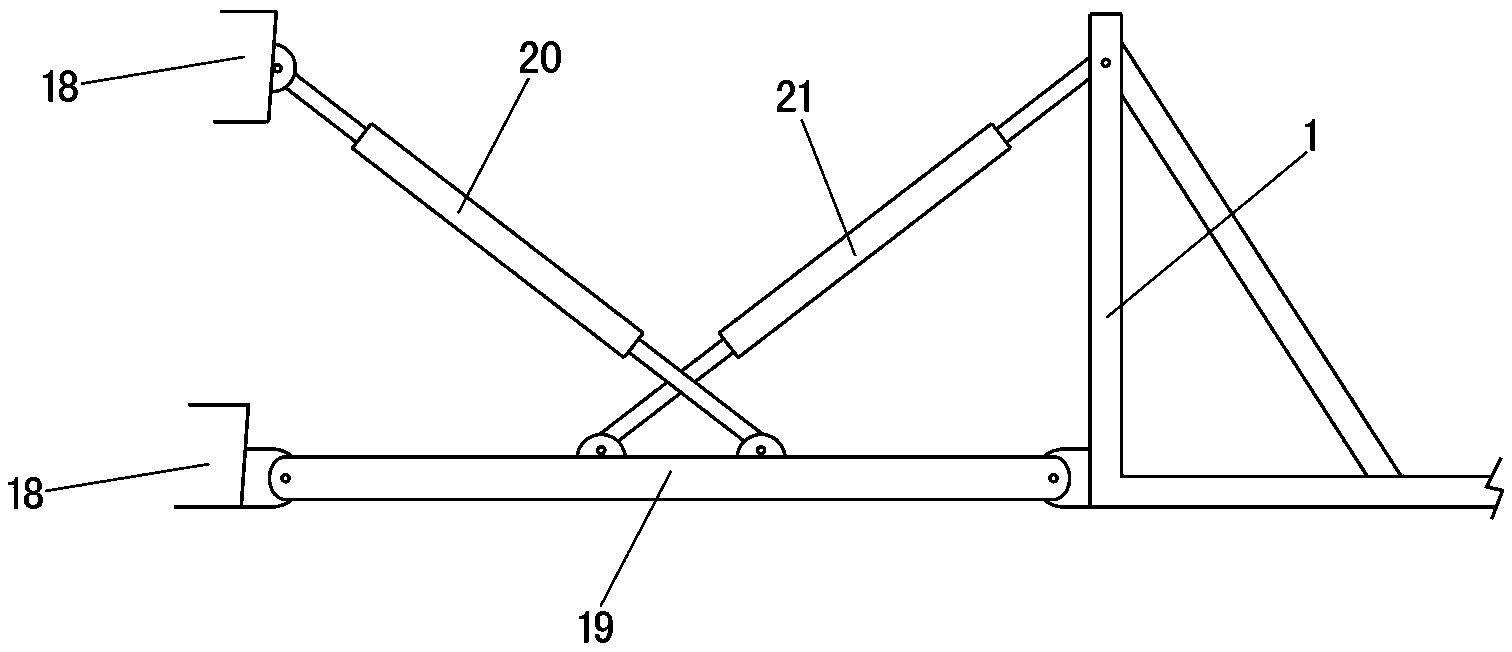

[0020] refer to figure 1 , figure 2 , the present invention comprises a frame 1, a walking wheel 2 supporting the frame, an onion unearthed blade 3 installed at the lower part of the front end of the frame, a rolling cage lifter 4 for the onion and soil mixture scooped up behind the blade, and a lifter The output end is connected to the onion and soil separation screen 5, which is connected to the screen surface by steel bars arranged in parallel in the longitudinal direction. The onion gathering and landing bucket connected to the output end of the separation sieve is 6. The gearbox 7 is installed at the front of the frame. The gearbox is connected to the power of the tractor. The longitudinal connection shaft between the output shafts, the driving sprocket 8 installed on the transverse power output shaft of the gearbox, the intermediate shaft 9 installed on the frame, and the two ends extend to both sides of the frame, installed on the intermediate shaft and the driving spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com