Self-exposure floating raft, rowed nori culture device and self-exposure method

A dry dew, lined technology, applied in the field of laver farming, can solve the problems of limited length and strength of struts, reduced laver quality, and inability to mechanized vegetable picking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

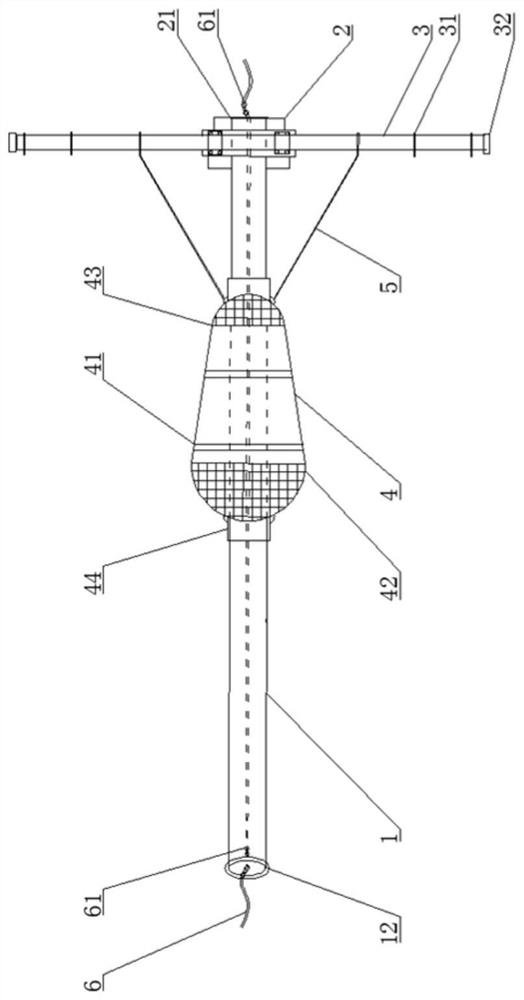

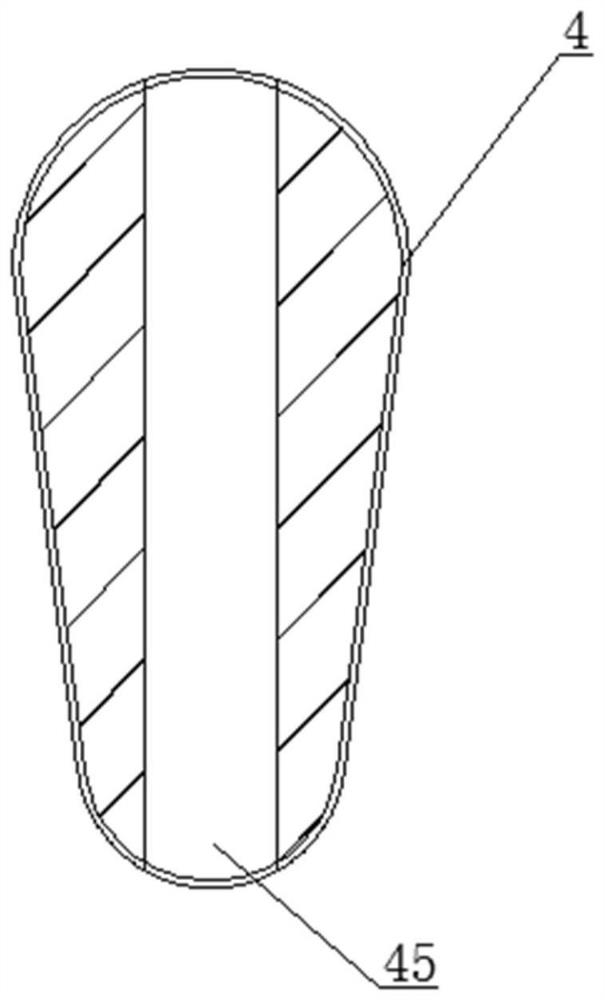

[0027] Example 1, refer to Figure 1-Figure 3 , a kind of anti-wind and wave type self-drying floating raft: comprising a hollow pick rod 1 and a floating rod 3, the head end of the hollow pick rod 1 is vertically fixedly connected with the middle of the floating rod 3, and a float is sleeved on the hollow pick rod 1 4. An oblique cable 5 is arranged between the float 4 and the float rod 3 , and a dry dew cable 6 is arranged inside the hollow rod 1 along the axis to lift the float rod 3 .

Embodiment 2

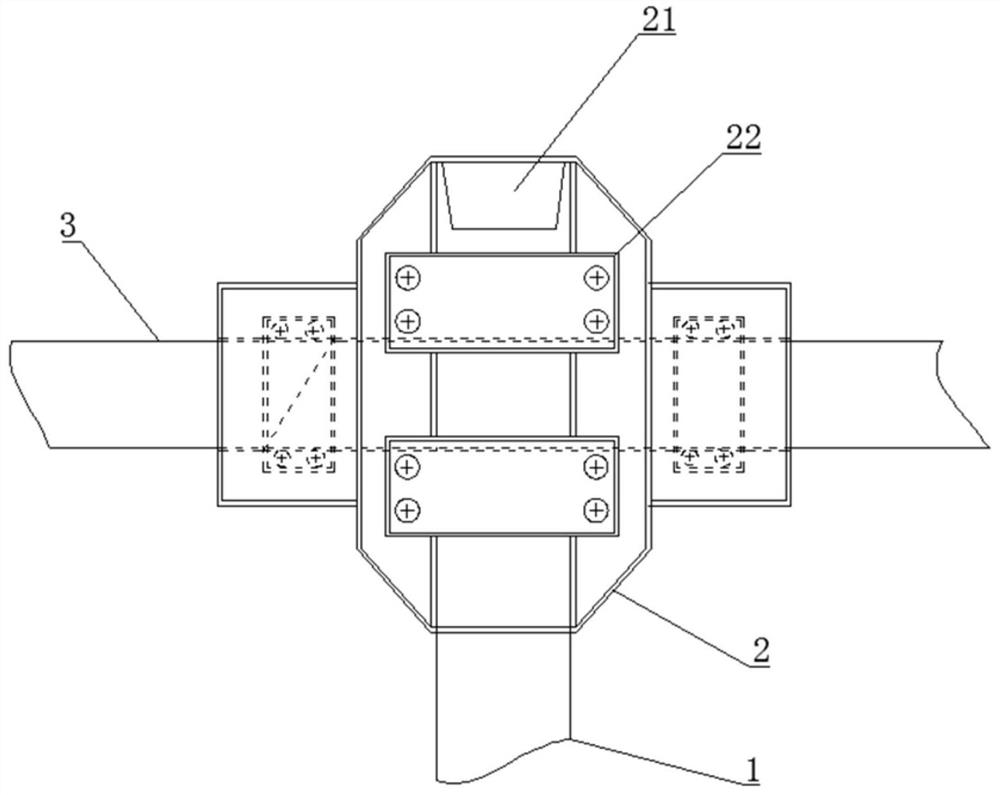

[0028] Example 2, in the anti-wind and wave type self-drying floating raft described in Example 1: the hollow pick rod 1 and the floating rod 3 are fixedly connected to each other in a vertical shape through the cross fastener 2, and the hollow pick rod 1 and the floating rod The rods 3 are respectively fixed in the cross fasteners 2 by two snap clamps 22;

[0029] When fixing, the snap clamp 22 is fixed on the cross fastener 2 with bolts, and is tightened with two nuts to prevent it from being washed away in the wind and waves of the sea.

Embodiment 3

[0030] Example 3, In the wind and wave-resistant self-drying floating raft described in Example 1: the rear end of the hollow pick rod 1 is installed with a wear-resistant pipe plug 12 with a through hole, and the head end of the hollow pick rod 1 is fixedly installed with a A wear-resistant pipe plug 21 with a through hole integrated with the cross fastener 2;

[0031]Pass the dry root cable 6 from the wear-resistant pipe plug 12 at the end of the hollow pick-up rod 1 into the hollow pick-up rod 1, and easily pass through the wear-resistant pipe plug 21 with holes at the head along the cavity of the hollow pick-up rod 1. Wear out; the wear-resistant pipe plug 21 and the cross fastener 2 are designed and manufactured as a whole to ensure that when the floating raft dries, the floating rod 3 will not slip off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com