Watering vehicle

A water tank and frame technology, applied in the field of watering trucks, can solve the problems of difficulty in achieving watering effect, waste of labor, excessive watering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

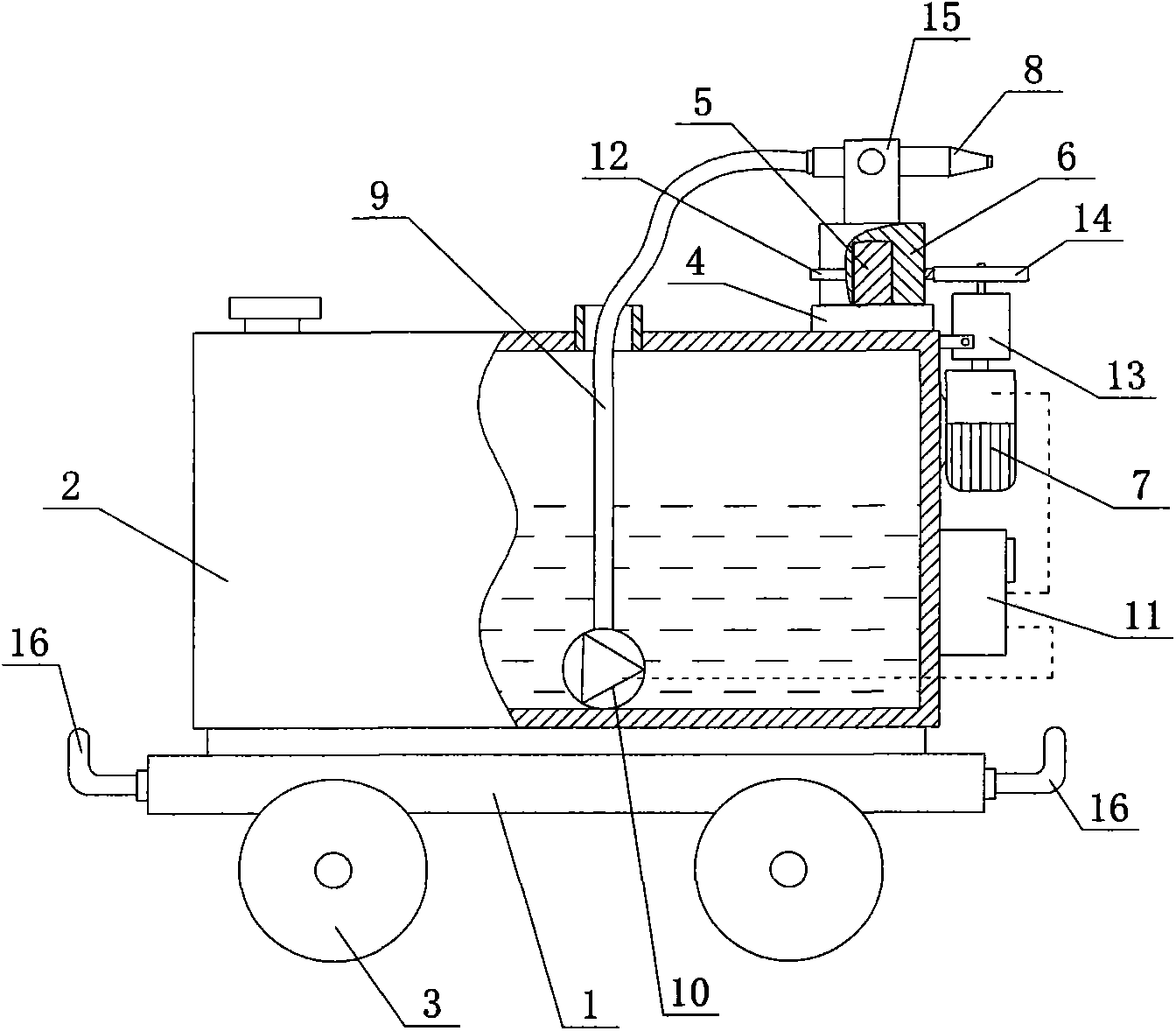

[0011] Referring to the accompanying drawings, the watering vehicle of the present invention comprises a vehicle frame 1, a water tank 2 installed on the vehicle frame 1 and a wheel 3 installed on the bottom of the vehicle frame 1, a slide 4 is installed on the water tank 2, and the center of the slide 4 Fixedly connected with a vertical rotating shaft 5, the rotating shaft 5 is fitted with a shaft sleeve 6 and the shaft sleeve 6 is driven and rotated by a motor 7 installed on the water tank 2; Water gun 8 is connected in the water tank 2 by suction pipe 9, and suction pipe 9 stretches into the bottom of water tank 2 and is connected with suction pump 10 at the bottom of suction pipe 9. A controller 11 is also installed on the water tank 2, and the control terminals of the motor 7 and the water pump 10 are all electrically connected to the above-mentioned controller 11. Suction pump 10 is started and stopped by controller 11 control, and motor 7 is a stepper motor, and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com