Method and apparatus for adopting low temperature unsaturated air to dehumidify

An unsaturated, low-temperature technology used in chemical instruments and methods, separation methods, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

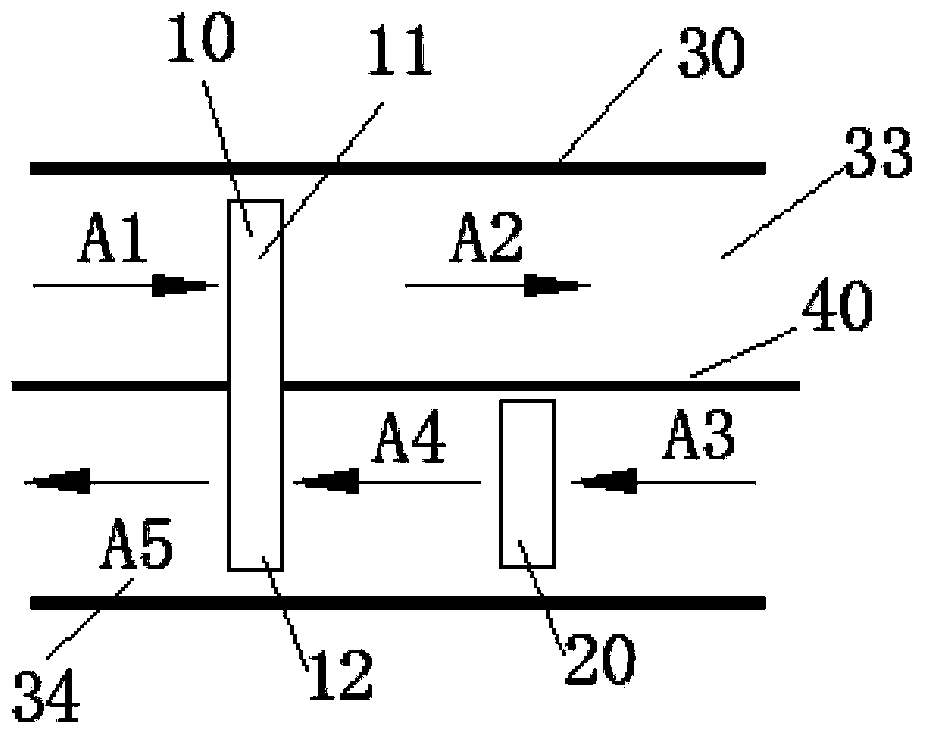

[0034] like figure 1 As shown, the device for dehumidifying using low-temperature unsaturated air in the present invention includes a dehumidification device 10, a precooling device 20, a housing 30, and a partition 40. The partition 40 divides the housing 30 into a regeneration channel 33 and a dehumidification channel 34. The dehumidification device 10 The regeneration side 11 of the dehumidification device 10 is placed in the regeneration channel 33 , and the dehumidification side 12 of the dehumidification device 10 and the pre-cooling device 20 are both placed in the pre-cooling device 20 . The low-temperature unsaturated air A1 regenerates the desiccant through the regeneration side 11 of the dehumidification device 10, and the treated air A3 is first cooled to a saturated state A4 by the pre-cooling device 20, and then dehumidified by the dehumidification side 12 of the dehumidification device 10 to become A5 , the low-temperature unsaturated air A1 and the processed ai...

Embodiment 2

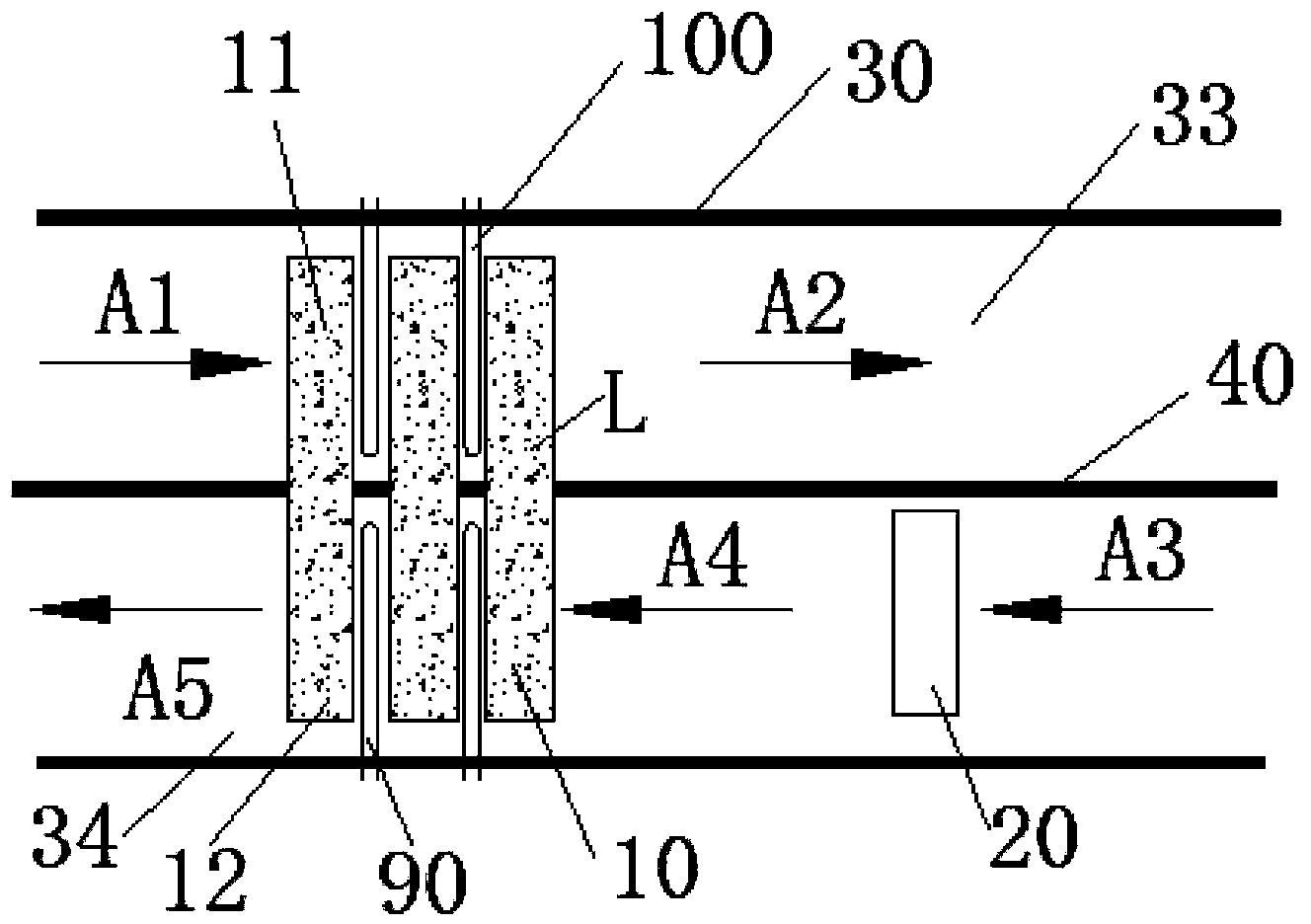

[0037] like figure 2 As shown, the dehumidification device 10 adopts an integral membrane dehumidification device, the solution L is on the inside of the membrane, and the air is on the outside of the membrane. The solutions on the dehumidification side 12 and the regeneration side 11 of the membrane dehumidification device are connected, and the solution is realized through diffusion or different densities. exchange. The difference between the air process and the first embodiment is that a heating element 100 is added between the membranes on the regeneration side 11 of the dehumidification device 10, and a cooling element is added between the membranes on the dehumidification side 12 of the dehumidification device 10. 90; that is, for the dehumidification side, there is a cooling element 90 to cool the air, and for the regeneration side, there is a heating element 100 to heat the air. In the figure, there are both the cooling element 90 and the heating element 100, or only ...

Embodiment 3

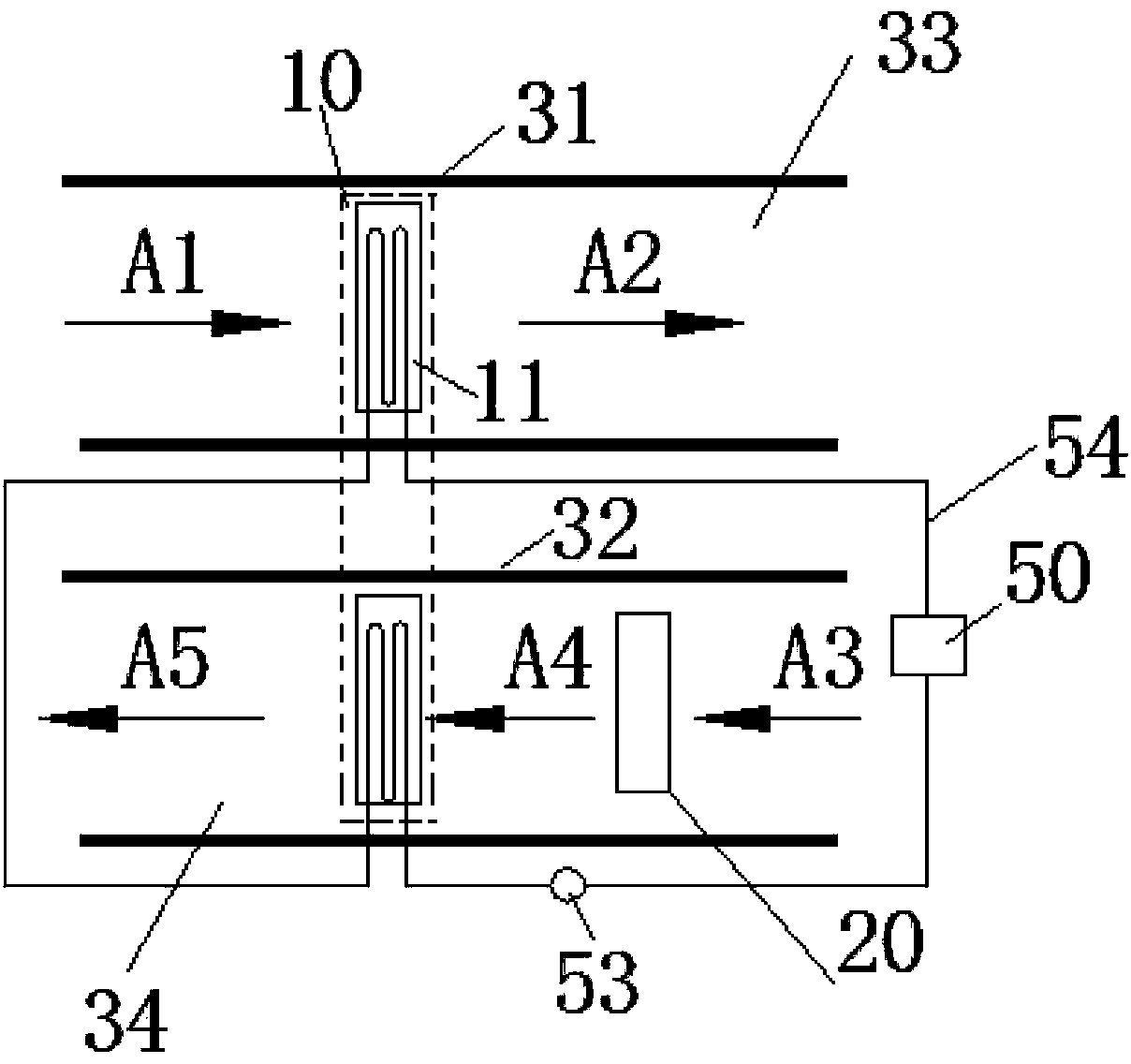

[0039] like image 3 As shown, the dehumidification device 10 adopts a separate dehumidification membrane. In this embodiment, the dehumidification device using low-temperature unsaturated air also includes a pump 53 and a solution tank 50, the regeneration side 11 of the dehumidification device 10, and the dehumidification side 12 of the dehumidification device 10. , the pump 53 and the solution tank 50 are connected into a closed loop through a pipeline 54 .

[0040] Solution circulation is driven by pump 53 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com