Engine subpackage line heavy plate chain

A sub-assembly line and engine technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of a single variety of conveyed objects, the line body does not bear heavy loads, and it is difficult to meet the diversification of production processes, so as to achieve ingenious and reasonable structure and smooth operation. smooth and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

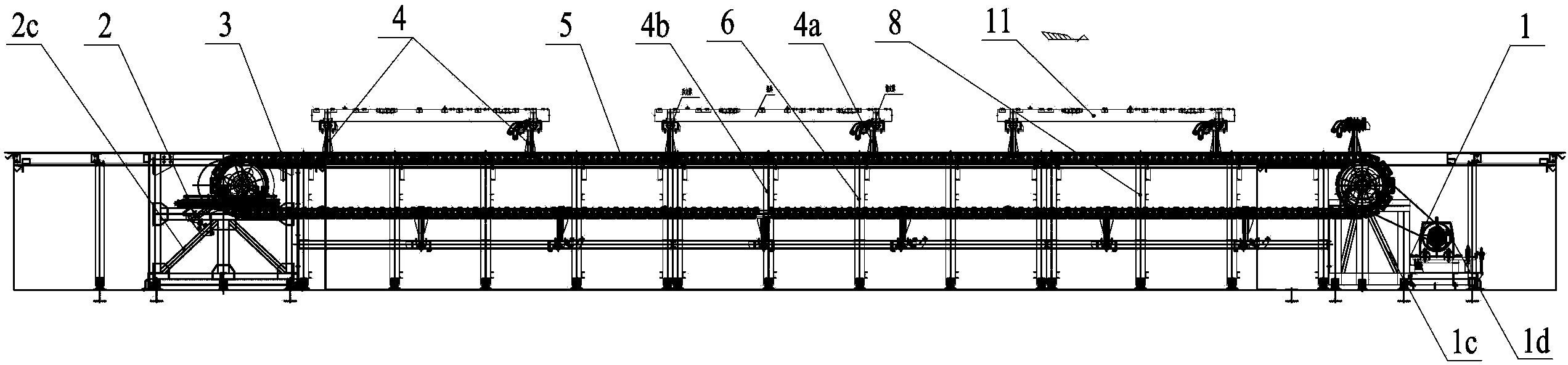

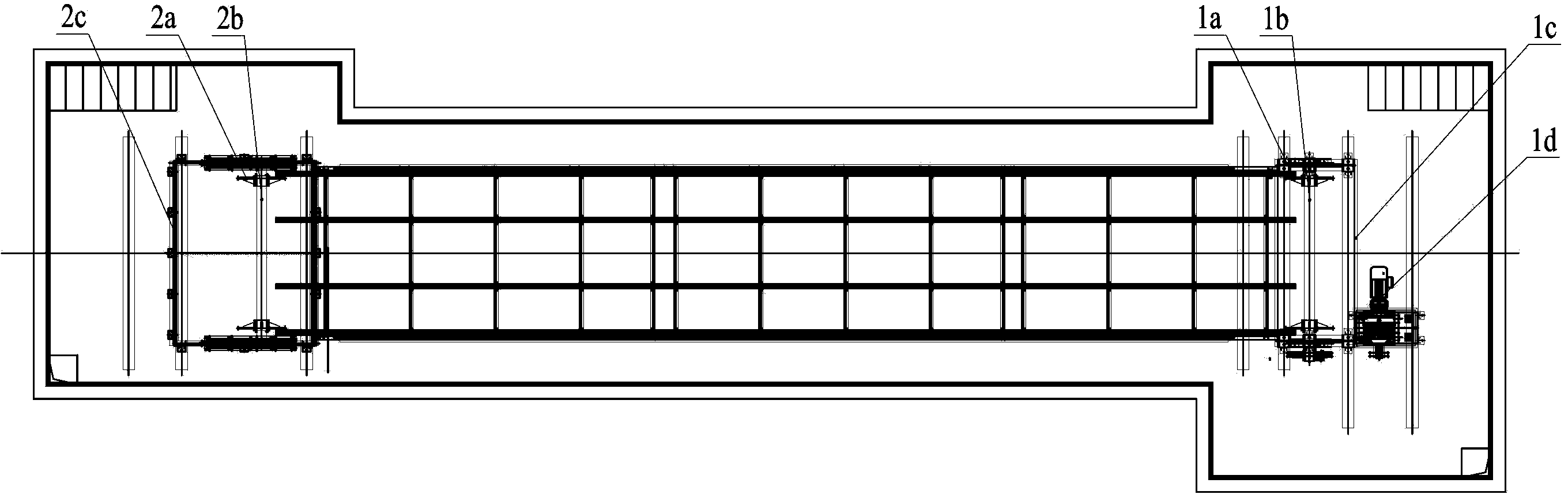

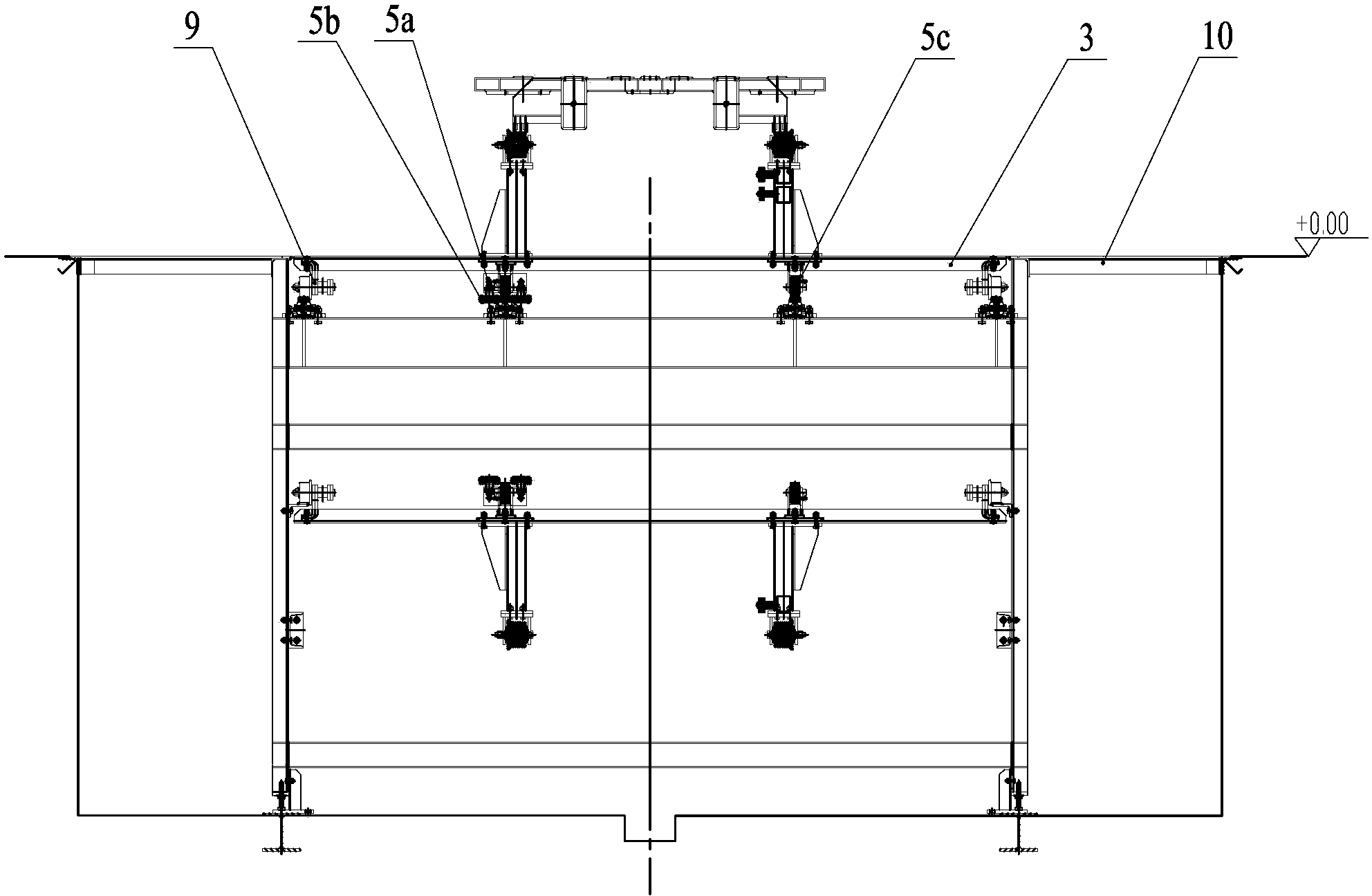

[0019] As shown in the figure: the heavy-duty plate chain of the engine subassembly line in the embodiment is mainly composed of a bearing track, a driving device 1, a tensioning device 2, a conveying chain 9, a bearing panel 3 and a skid body support 4, and the driving device 1 and The tensioning device 2 is respectively arranged on the two ends of the bearing track, and the conveying chain 9 is meshed and connected on the driving sprocket 1a of the driving device 1 and the tensioning sprocket 2a of the tensioning device 2, and the conveying chain 9 is equipped with A plurality of load-bearing panels 3 connected end to end, wherein the upper end surfaces of several load-bearing panels 3 are connected with pry body support 4, and both sides of the ends of the lower end surfaces of all load-bearing panels 3 are connected with conveyor chains 9, and the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com