Magnetic suction through combined floor drain

A combined, magnetic suction technology, used in waterway systems, indoor sanitary pipe installations, drainage structures, etc., can solve the problems of great influence of the downward moving distance of the sealing cover, slow drainage speed, and inability to reset, so as to ensure deodorization. Deodorizing effect, improving drainage speed, and increasing the effect of moving down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

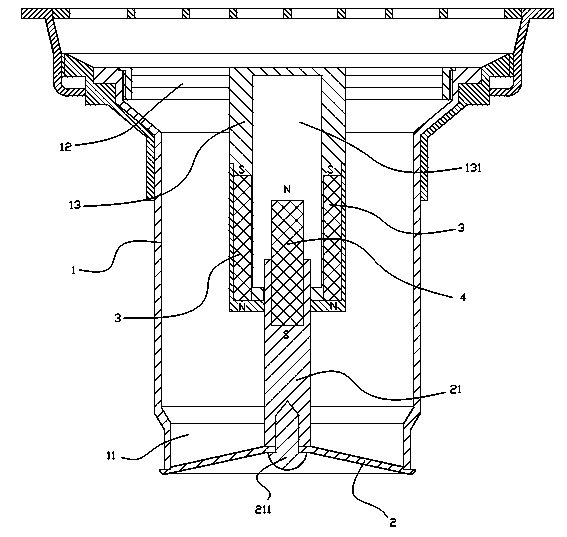

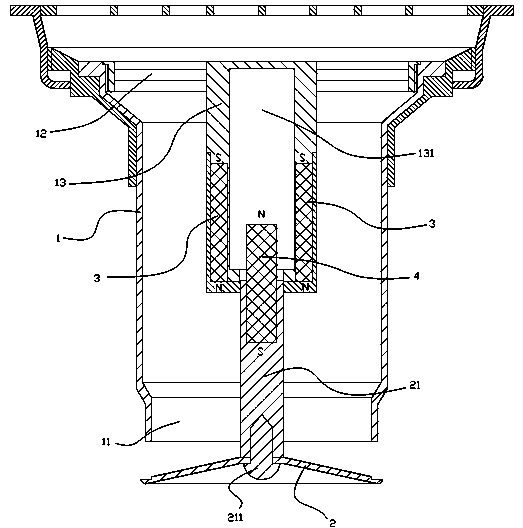

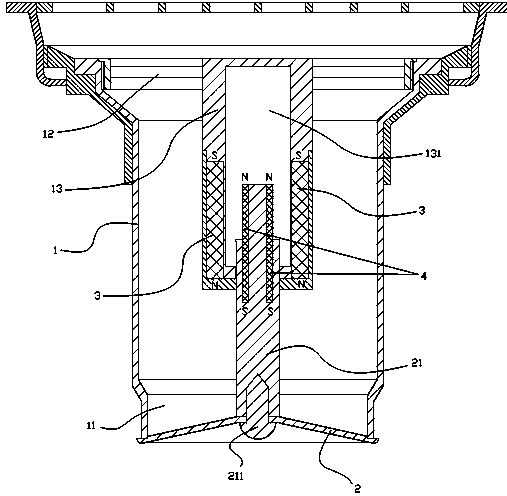

[0053] like Figure 14-15 As shown, it is the seventh embodiment of the present invention, the magnetic poles of the outer magnetic strip 3 are distributed on both sides inside and outside, and the magnetic poles of the inner magnetic strip 4 are also distributed on the two side walls, and the outer magnetic poles of the inner magnetic strip 4 and the corresponding positions The magnetic poles at the inner ends of the outer magnetic strips 3 are the same. In the figure, the left magnetic pole of the inner magnetic strip 4 is N and the right magnetic pole is S, the inner magnetic pole of the corresponding left outer magnetic strip 3 is N, and the inner magnetic pole of the right outer magnetic strip 3 is S.

[0054] When not draining water, the inner magnetic strip 4 is located at the middle and upper part of the outer magnetic strip 3 under the same and repulsive effect as the inner magnetic pole of the corresponding side outer magnetic strip 3 . When draining water, the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com