Oil pipe for automobile

A oil pipe and automobile technology, which is applied in the field of automobile oil pipe accessories, can solve the problems of waste materials in the production process, and achieve the effects of prolonging service life, simple structure, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

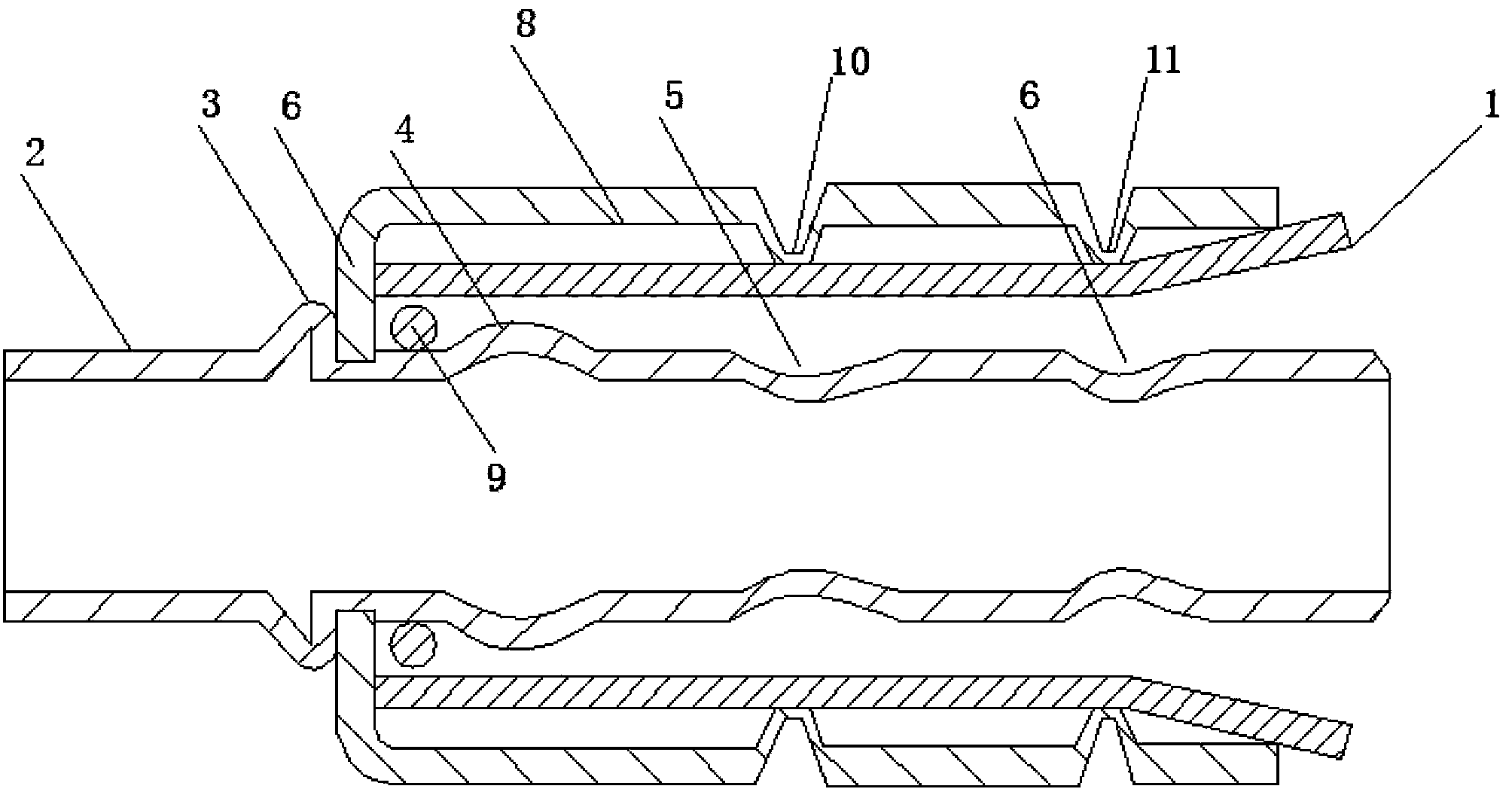

[0010] Such as figure 1 As shown, the oil pipe used for automobiles includes a rubber pipe 1 for oil passage and a metal pipe 2 for connection. One end of the metal pipe 2 is inserted into the rubber pipe 1, and the metal pipe 2 is sequentially provided with a limiting protrusion 3 and a clamping joint. Protrusion 4 and two clamping grooves 5, 6, the limit protrusion 3 is provided with a card slot on the side, and the end of the metal sleeve 8 is provided with a tab 7, and the tab 7 extends into the card slot against the limit protrusion 3, the metal sleeve 8 is set on the peripheral surface of the rubber hose 1 to fix the rubber hose 1, and an annular tension ring 9 is provided between the clamping protrusion 4 and the tongue 7.

[0011] Wherein, the metal sleeve 8 is also provided with two buckles 10, 11, and the two buckles are correspondingly matched with the buckling grooves on the metal pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com