Detection device for detecting liquid crystal module

A detection device and liquid crystal module technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of increasing product defect rate, high product defect rate, slow production speed, etc. The effect of minimizing the height of the jig and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

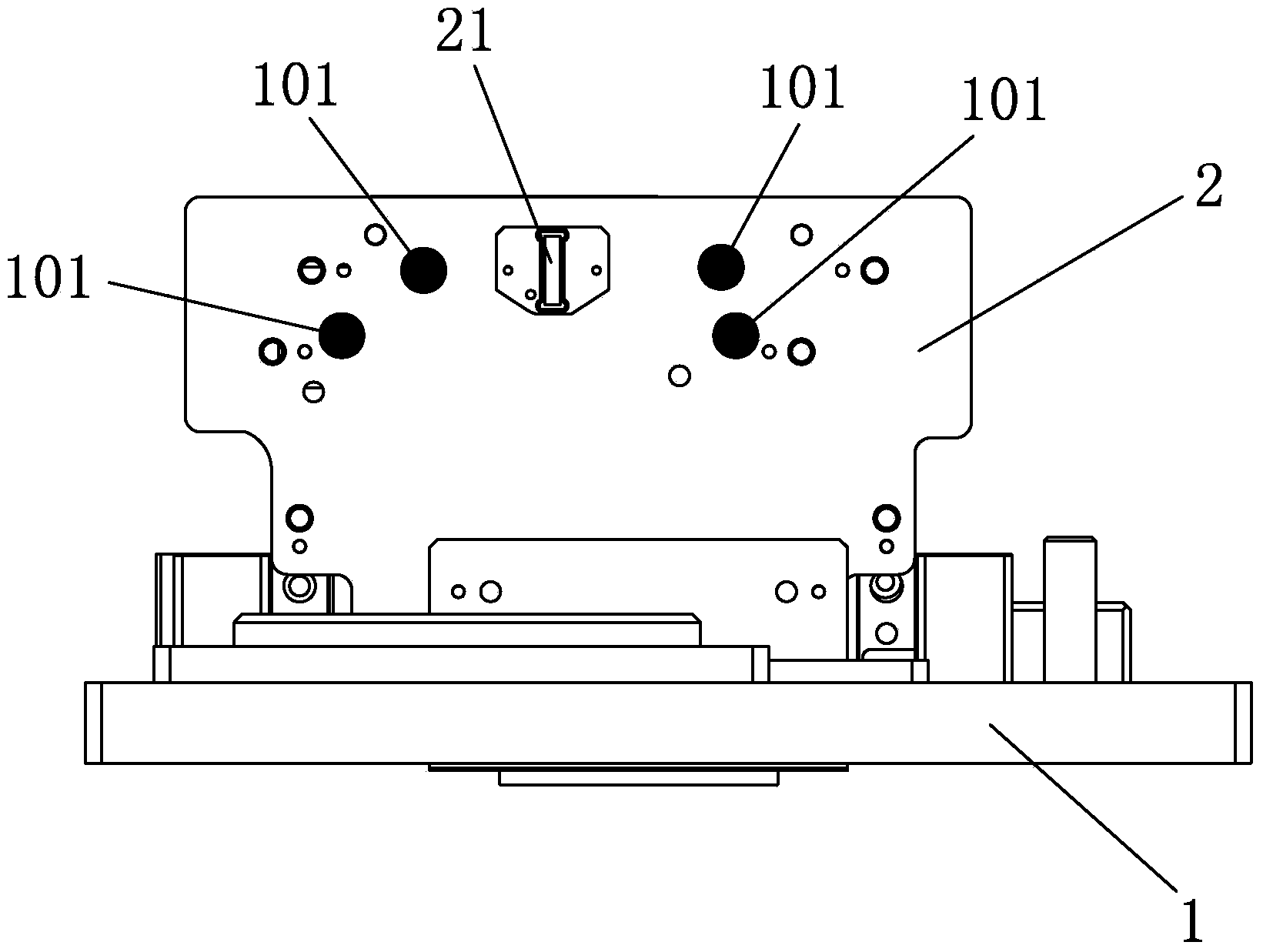

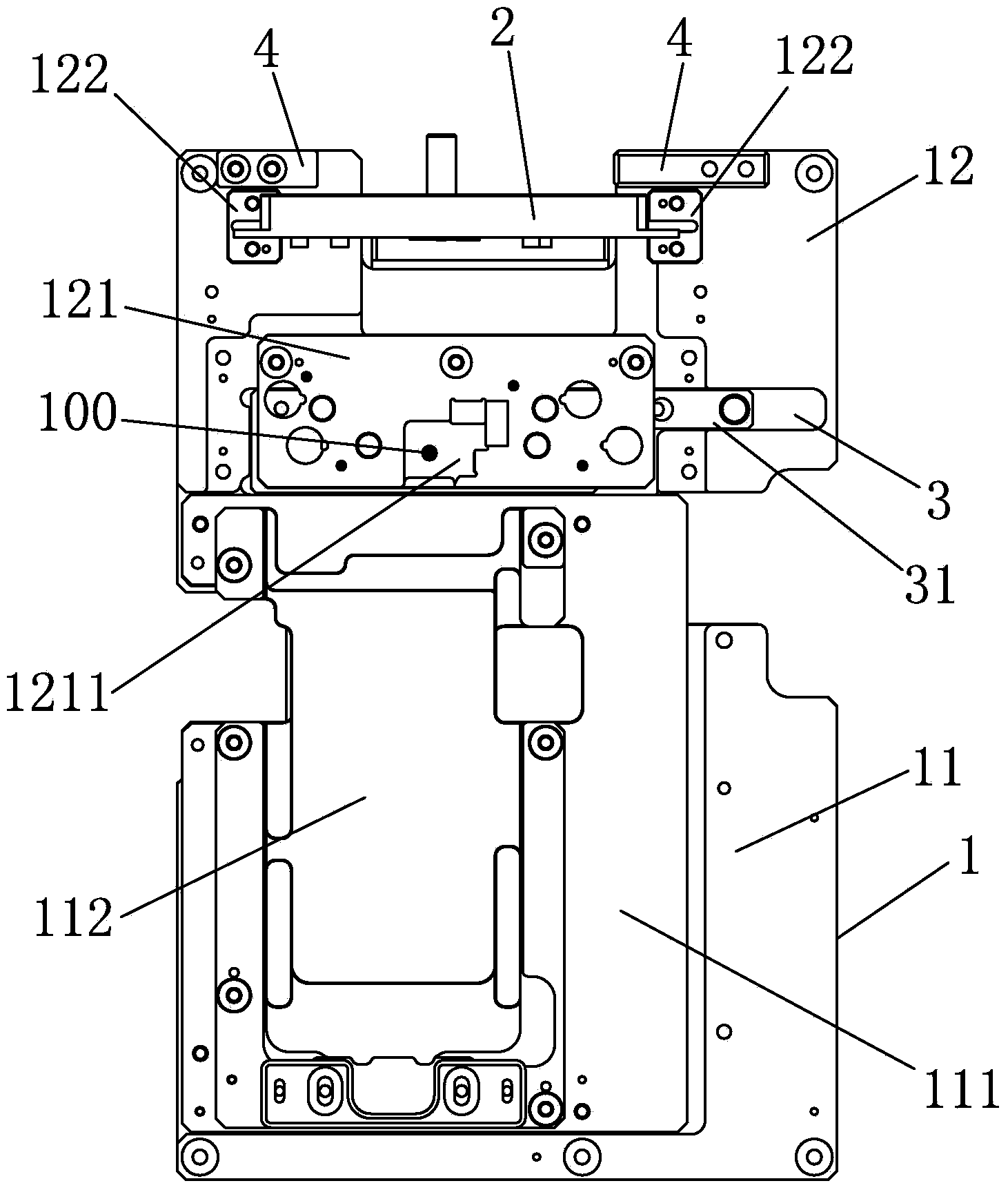

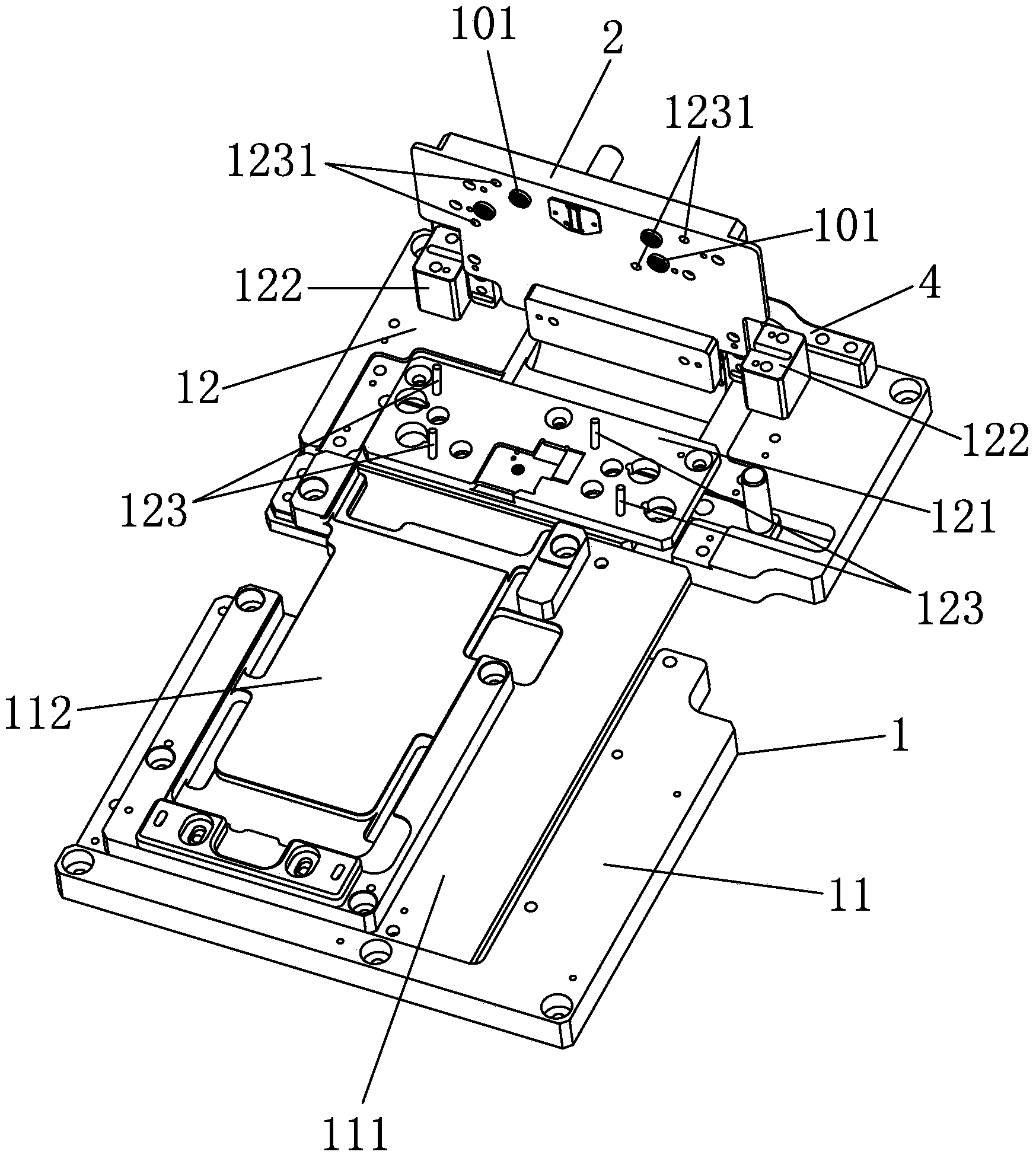

[0075] like Figures 1 to 23 As shown, a detection device for liquid crystal module detection, the detection device includes a top plate 1 and a first detection substrate 2; the first detection substrate 2 is provided with a connection for detecting the connector of the module to be tested tor detection port 21. (see figure 1 )

[0076] The top plate 1 includes a first top plate 11 and a second top plate 12; the first top plate 11 is sequentially provided with a backing plate 111 fixedly connected with the first top plate 11 and a backing plate 111 connected with the first top plate 11; The module supporting plate 112 to which the backing plate 111 is affixed, the module to be tested is placed on the module supporting plate 112.

[0077] The plate surface of the second second plate 12 is fixed with a limiting plate 121, which is provided with a cavity 1211 for placing the connector port of the module to be tested; the limiting plate 121 is used for positioning the module to...

Embodiment 2

[0093] The difference between this embodiment and Embodiment 1 is that: the first detection substrate is rotatably connected to the second plate through a hinge; the turned first detection substrate and the limit plate are matched and crimped together.

Embodiment 3

[0095] The difference between this embodiment and Embodiment 1 is that at least one second magnet is provided on the first detection substrate, and a metal connection part matching the position of the second magnet is provided on the surface of the limiting plate. ;

[0096] After the first detection substrate is overturned, through the cooperation of the second magnet and the metal connection part, the inner plate surface of the first detection substrate and the matching one are crimped on the plate surface of the limiting plate.

[0097] This embodiment utilizes the principle that magnets and metals attract each other. When the first detection substrate is in crimping contact with the limit plate, the second magnet and the metal connection part are attracted and docked, and the suction force makes the connector detection port on the first detection substrate Conduction with the connector port of the module under test to achieve the purpose of detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com