Pen type cutter

A tool and pen-type technology, which is applied in the field of pen-type tools for testing the film layer on the surface of workpieces, can solve the problems of easy wear of the blade, damage and bluntness of the blade, and high cost, so as to improve the marking efficiency, facilitate replacement, and reduce the cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

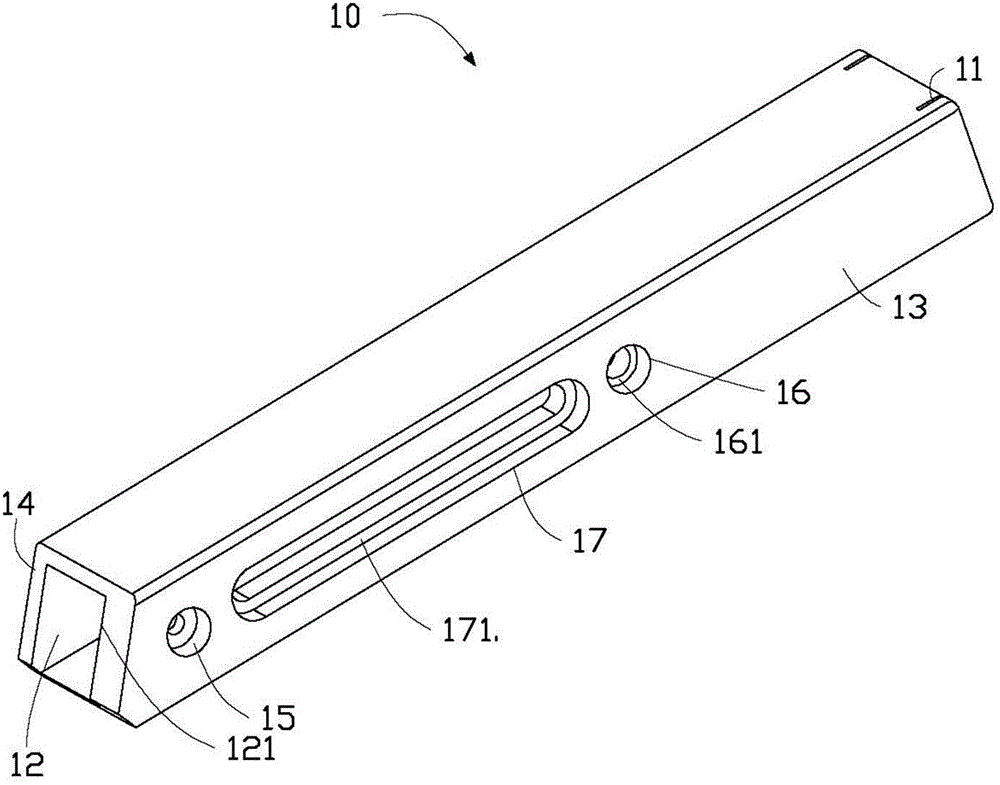

[0017] Embodiments according to the present invention will be described with reference to the drawings. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

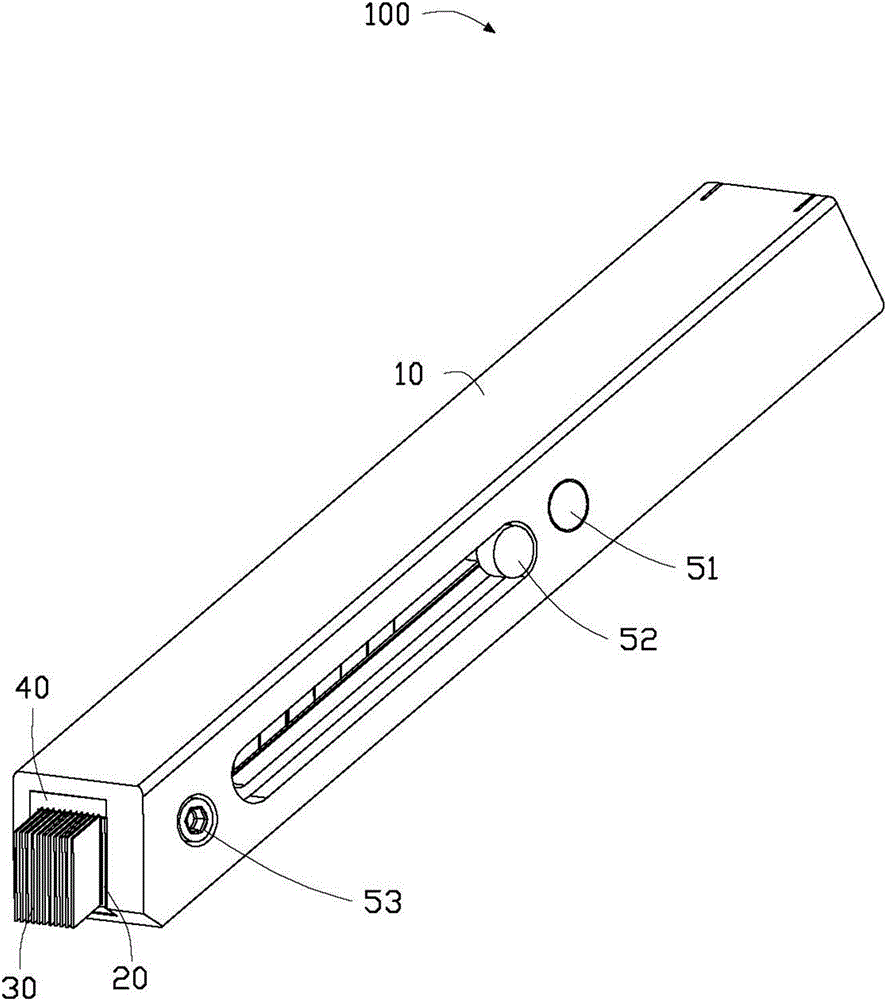

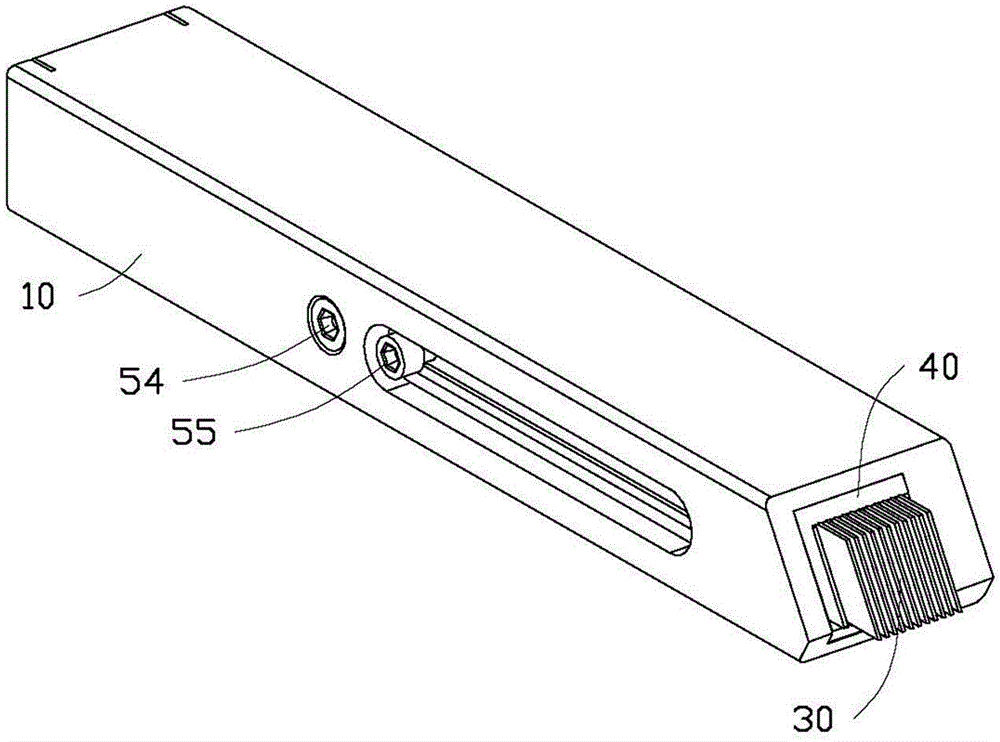

[0018] Please refer to figure 1 and figure 2 , the pen tool 100 of the present invention includes a hollow cylindrical handle 10, a plurality of spacers 20 completely accommodated in the handle 10, a plurality of pads 20 partially accommodated in the handle 10 and spaced apart from the plurality of spacers 20. The blade 30 and the limiting frame 40 located at the port of the handle 10 to limit the sliding of the blade 30 . A plurality of spacers 20 are locked into the knife handle 10 through the spacer locking member 51, and a plurality of blades 30 are arranged at intervals between the plurality of spacers 20 and locked into the knife handle 10 through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com