Filter element device, filter and application of filter

A filter and filter element technology, which is used in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of uncompact structure, the filter cannot be used for filtering high-temperature molten salt, and the floor space is large. Achieve reasonable and compact structure, reduce the risk of pipeline blockage, and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

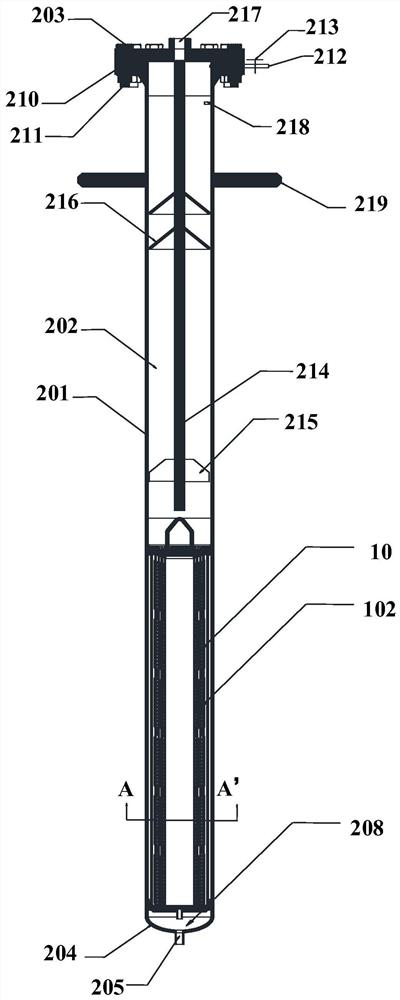

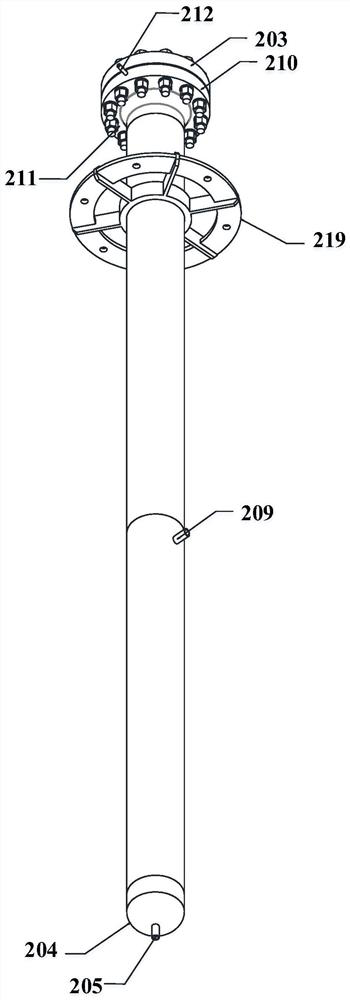

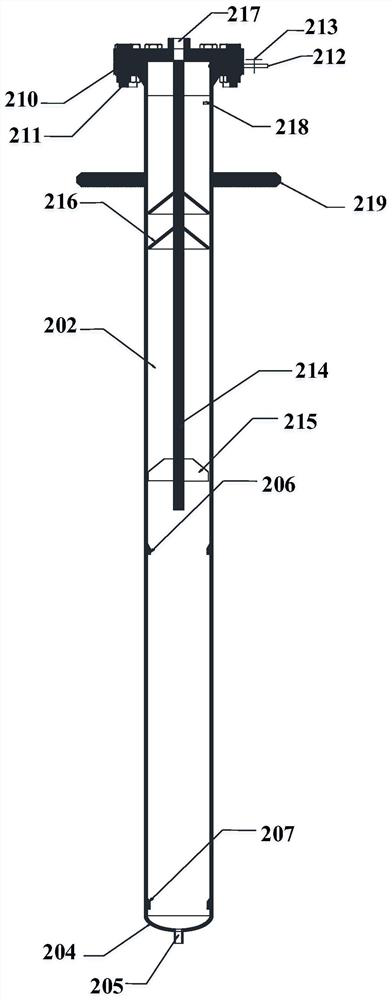

[0066] The schematic view of the longitudinal section of the filter in this embodiment is as follows: figure 1 Shown; the schematic diagram of the three-dimensional structure of the filter is shown in figure 2 Shown; The schematic diagram of the longitudinal section of the filter without the filter element device is shown in image 3 Shown; The schematic diagram of the longitudinal section of the filter element device is shown in Figure 4 shown; the bottom view at the A-A' cross-section is as follows Figure 5 shown.

[0067] The filter element device 10 includes a filter element housing 101, two filter assemblies 102 and an inner cylinder 103 which are sheathed sequentially from outside to inside. There is a first channel 104 between the filter assembly 102 and the filter element housing 101. Distributor 109 is arranged, and filter element liquid inlet 105 is arranged longitudinally on the distributor, and distributor 109 is used for evenly distributing the liquid to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com