Servo mechanism load simulator

A technology of load simulator and servo mechanism, which is applied to simulators, simulators of space navigation conditions, instruments, etc., and can solve problems such as inaccurate simulated loads and large vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

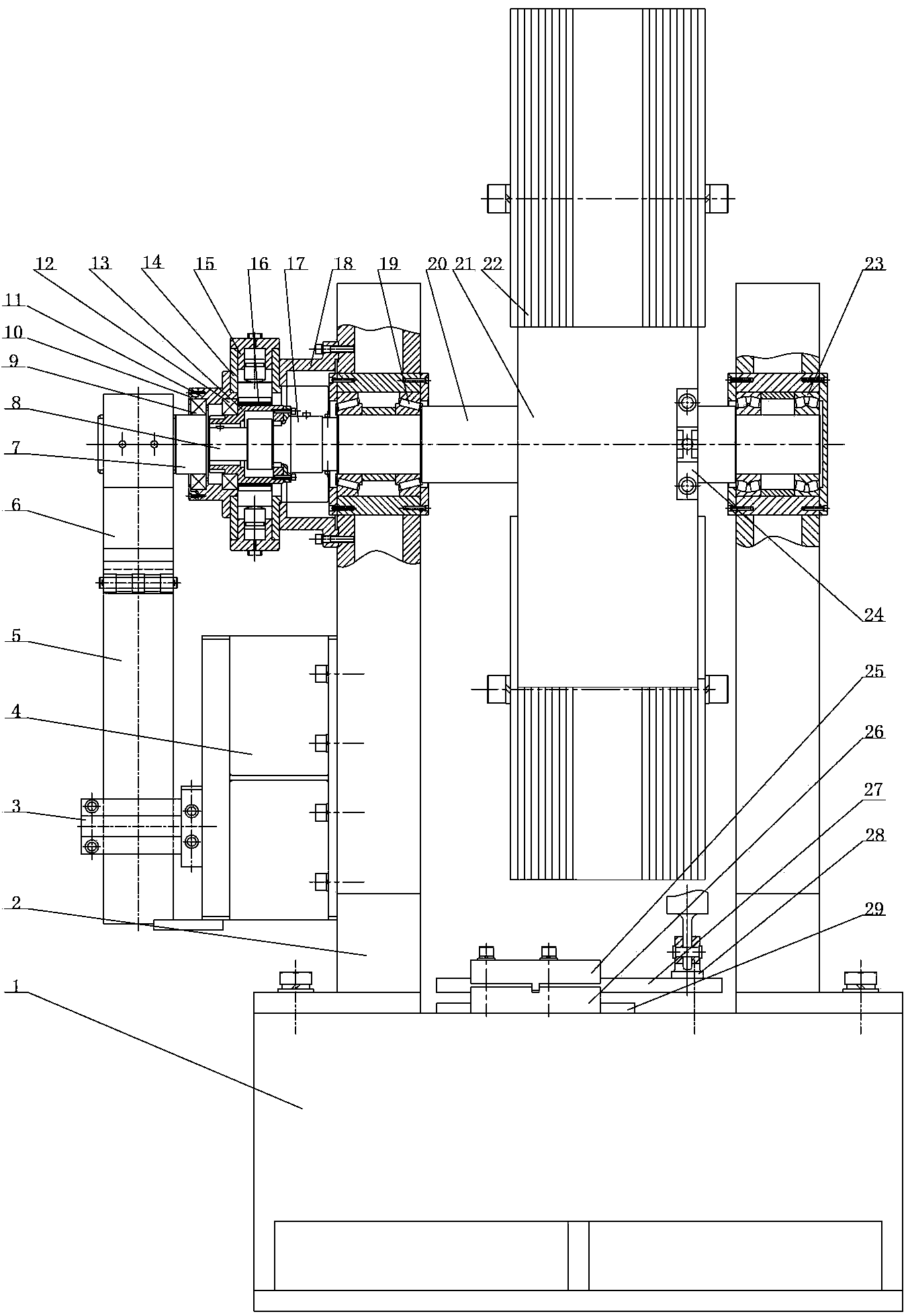

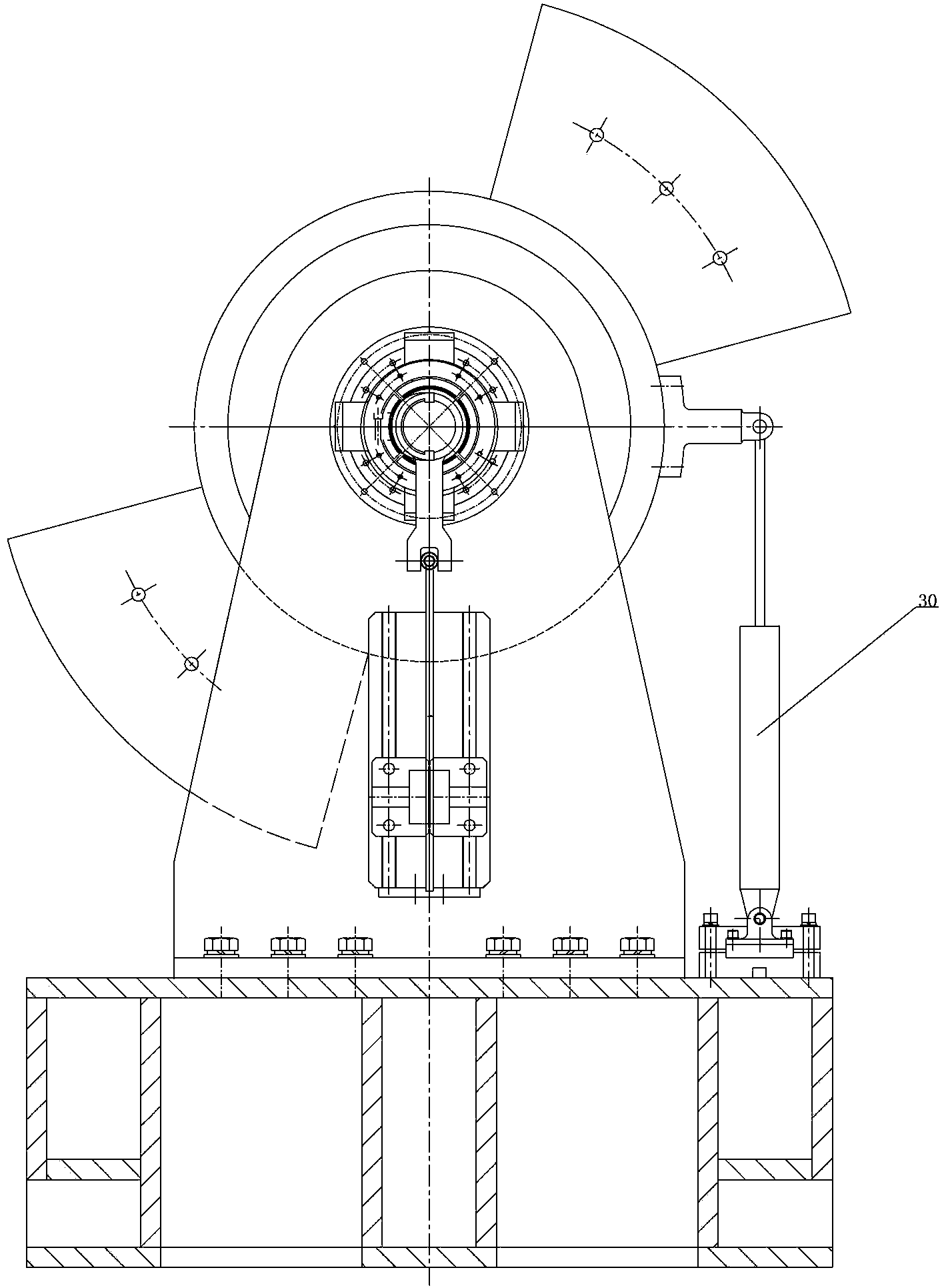

[0077] See figure 1 , figure 2 , a servomechanism load simulator of the present invention, it is to do the ground load loading test to the servomechanism of rocket tail nozzle. The composition of the servo mechanism load simulator specifically includes:

[0078] One base 1, two side vertical plates 2, two elastic moment spring plate clamping plates 3, one elastic moment loading support 4, one elastic moment spring plate 5, one swing fork 6, one elastic moment rotating shaft 7, one Elastic moment sensor 8, two ball bearings 9, 12, a bearing cover 10, a bearing seat 11, a friction shaft 13, a small oil cylinder mounting seat 14, four friction torque loading small oil cylinders 15, four friction plates 16, A friction torque sensor 17, a mounting base 18, two roller bearings 19, a main shaft 20, an inertia base plate 21, an inertia counterweight plate 22, two spherical roller bearings 23, an upper lug 24, a A support spring plate cover plate 25, a support spring plate base 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com