A hybrid integrated circuit and its manufacturing method

A hybrid integrated circuit and manufacturing method technology, applied in circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficulty and workload, damage to metallization layers, affect conductivity and corrosion resistance, etc. The effect of improving component performance, reducing placement difficulty, improving assembly operability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

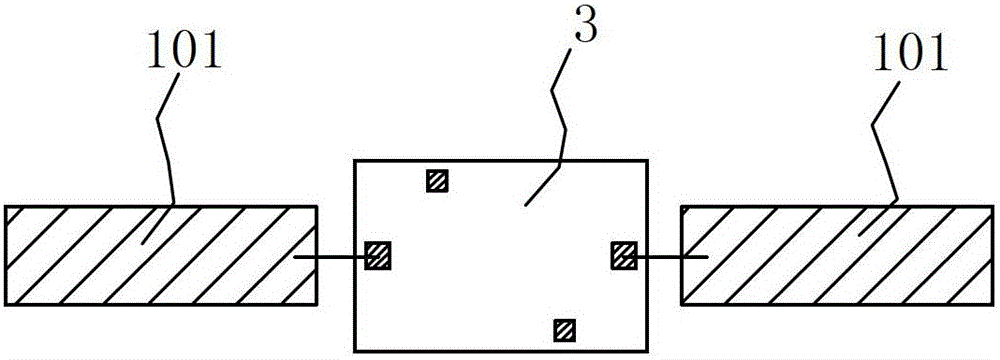

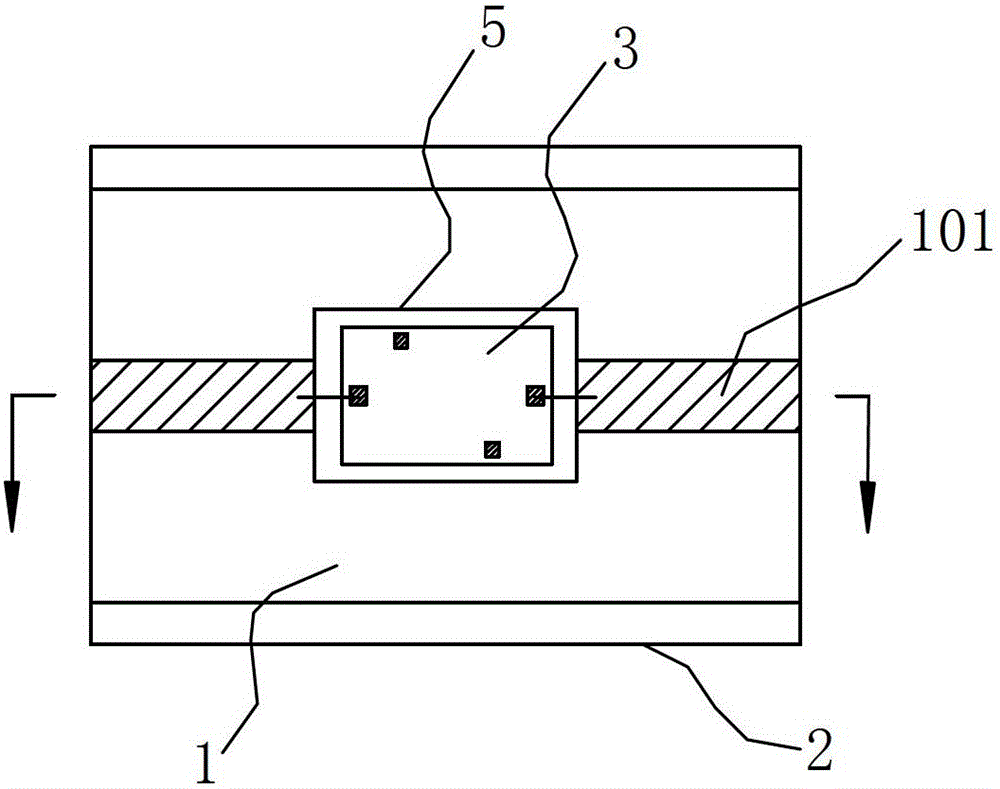

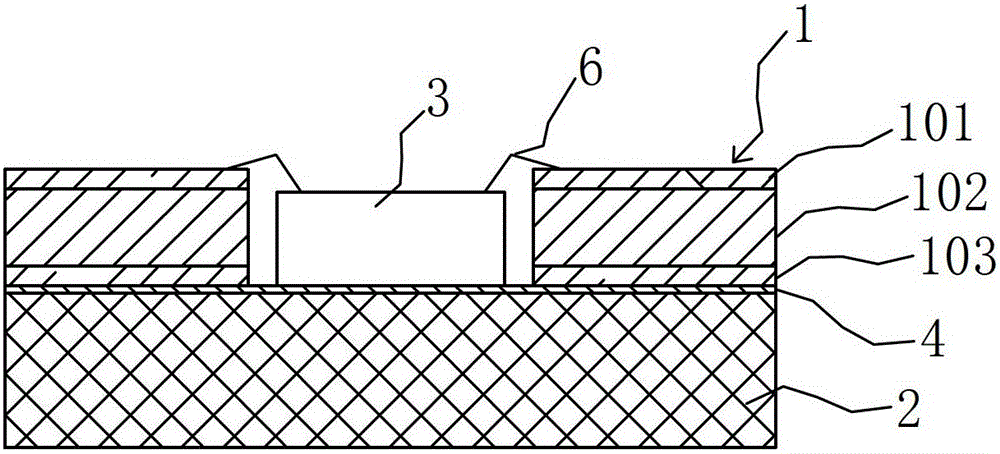

[0045] The present invention is based on the manufacturing technology of polytetrafluoroethylene soft dielectric circuits commonly used in hybrid integrated circuits, improves the processing form of the MMIC chip integration groove 5 in the traditional circuit, and processes the MMIC chip integration groove 5 into a blind groove 10 form , retaining the ground metal layer 103 on the original polytetrafluoroethylene circuit substrate, thereby reducing the bonding or welding difficulty of the MMIC chip 3, and improving the yield and reliability.

[0046] The specific solutions adopted by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] combine Figure 6-Figure 21 ,in Figure 6-Figure 15 It shows the structural change diagram of the polytetrafluoroethylene copper clad laminate during the processing of the circuit substrate; Figure 16-Figure 21 A schematic diagram showing the structure of each stage in the hybrid int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com