Electrode Structure for New Resistance Furnace

A technology of electrode structure and resistance furnace, which is applied in the direction of electric furnace heating, furnace, electric heating device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

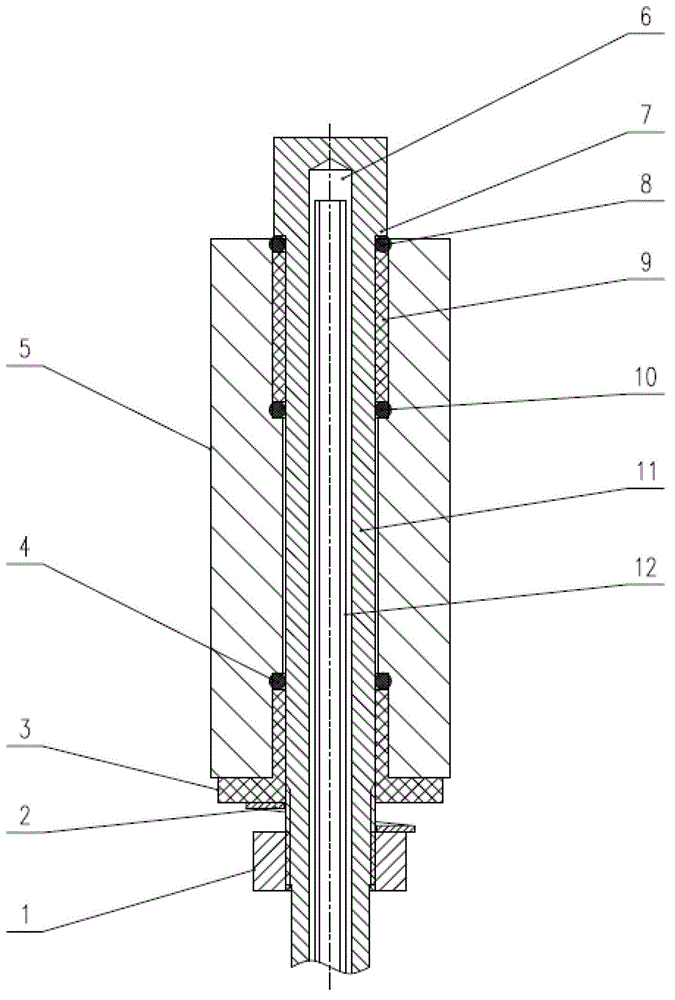

[0045] Such as figure 1 As shown, a novel electrode structure for a resistance furnace provided by the present invention includes an electrode base 5, and the center of the electrode base 5 has a hole with upper and lower steps. The electrode 11 is provided with a shaft shoulder 7 on the top of the electrode 11, and the outer diameter of the shaft shoulder 7 of the electrode 11 is 1 mm smaller than the inner diameter of the step hole at the top of the center hole of the electrode seat 5. The inner diameter of the central hole of the electrode seat 5 is 2mm larger than the outer diameter of the electrode 11. The inside of the electrode 11 is provided with a cooling hole 6, and the bottom of the electrode 11 is threaded. The electrode 11 passes through the center of the hole of the electrode seat 5, the top goes deep into the device, and the bottom is outside the device.

[0046] The electrode 11 is connected with the tightening nut 1 through the bottom thread, and the upper p...

Embodiment 2

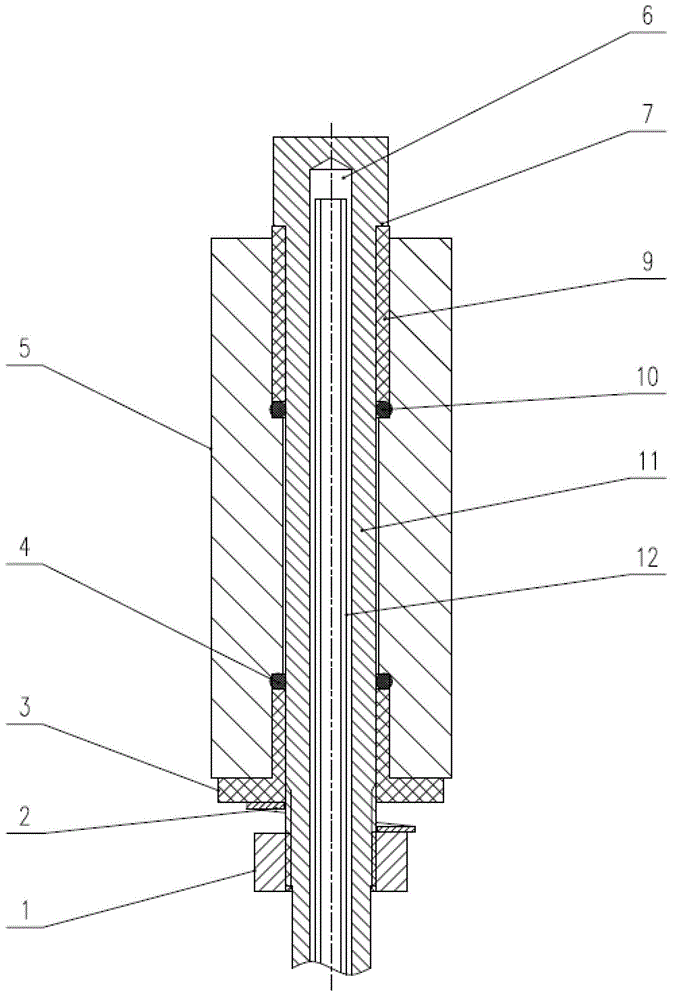

[0051] according to figure 2 As shown, the present invention provides a new electrode structure for electric resistance furnace. Another embodiment of the present invention differs from this embodiment in that the top of the polytetrafluoroethylene cylinder 9 is in direct contact with the shaft shoulder 7 . The sum of the height of the polytetrafluoroethylene cylinder 9 and the wire diameter of the middle O-ring 10 is 2.5 mm larger than the height of the upper step in the center hole of the electrode holder 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com