Pouch having concavely-curved corners

A cornered, curved technology for sachets that addresses issues such as increased complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

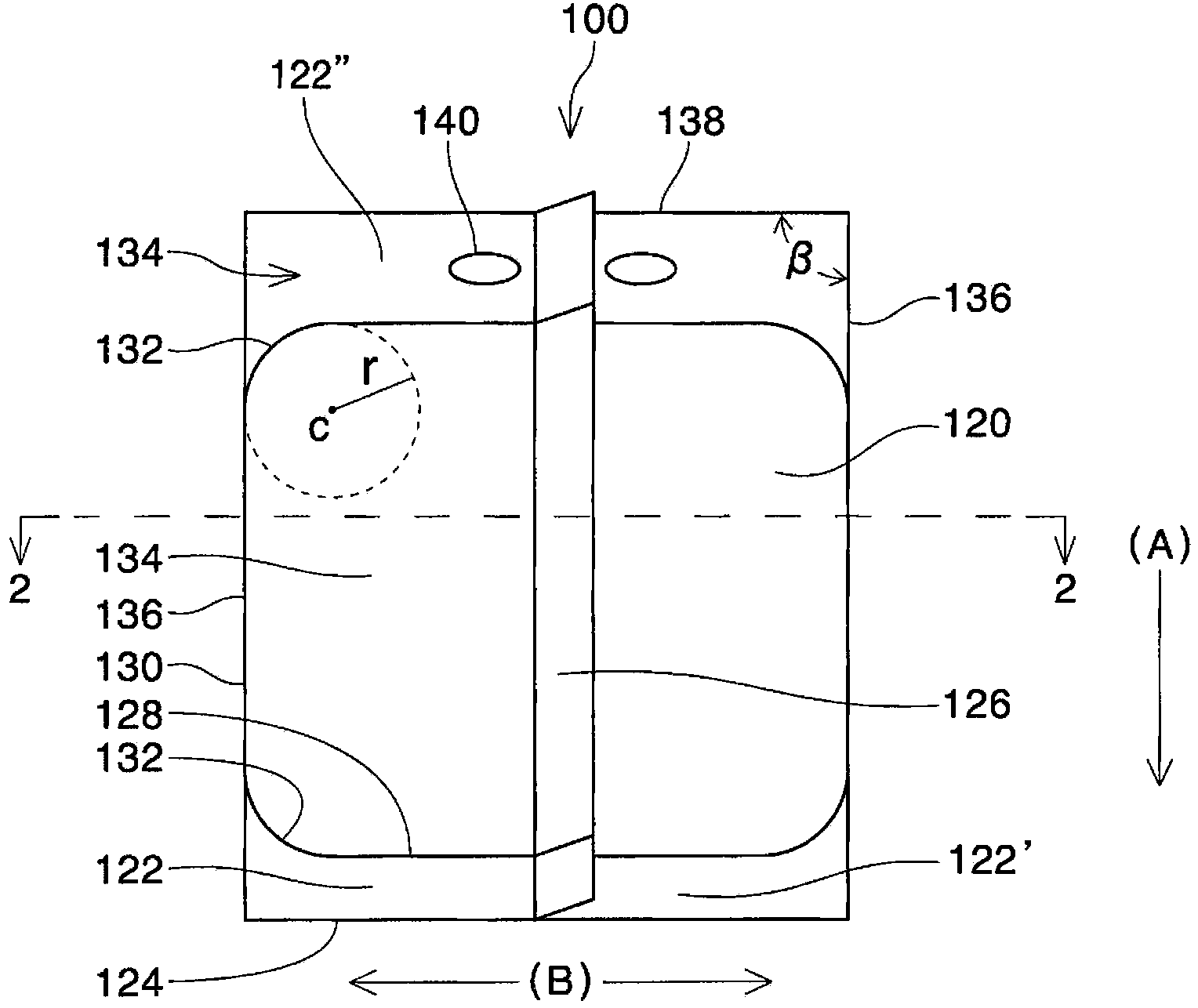

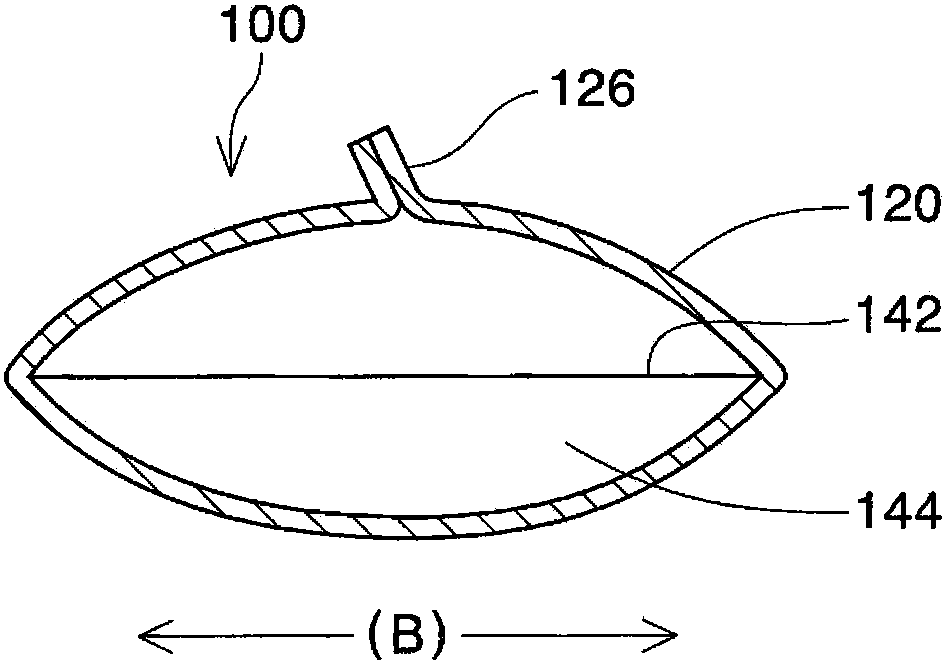

[0059] according to figure 1 and figure 2 The sachets are used on VFFS machines with Figure 6-7 Similar sealing clips are formed from thin sheets. The VFFS machine creates the overall seal by heating the sealing jaws to create a thermal bond between the individual sheets. Sheets are film materials polyethylene terephthalate, metal films (e.g. ) and a three-layer laminate of polyethylene. The flakes are provided on rolls fed into the VFFS machine and drawn onto the area where the tube is formed by sealing the fin seals in the machine direction. The tube has a leading edge which is used according to the Figure 6-7 The sealing clip seals to form a leading edge seal. A predetermined weight (~1.7kg) of granular laundry detergent is filled into the tube and allowed to settle in the tube, and use Figure 6-7 The sealing tab seals the tube to form a filled pillow sachet containing granular laundry detergent. The process is then repeated for the next sachet.

[0060] acco...

example 2

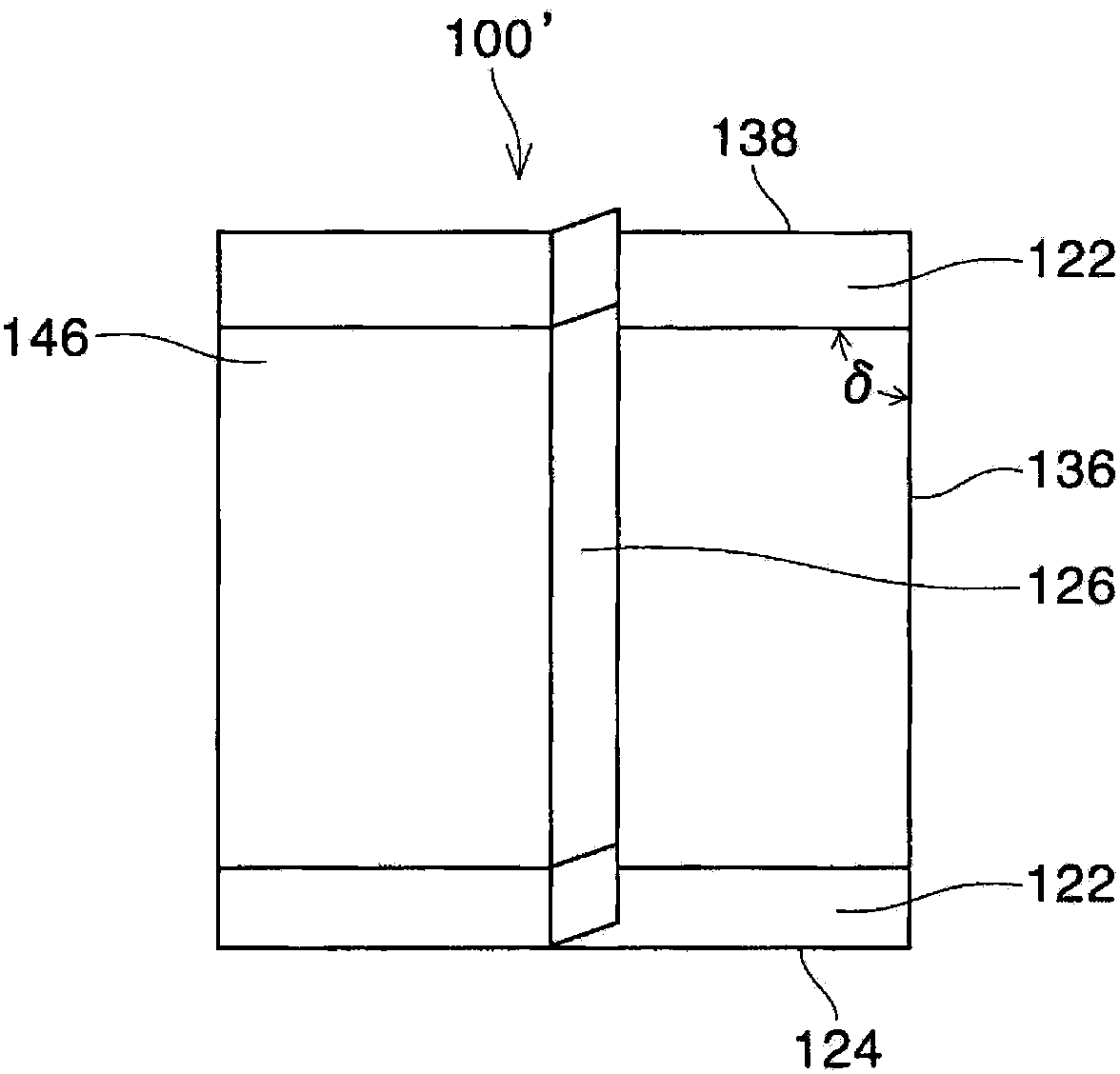

[0066] The ability of the sachets of the present invention to reduce quality defects during shipment was also tested. Here, prepare in the same manner as described in Example 1 Figure 1-2 , and fill it with a predetermined weight (~1.55kg) of granular laundry detergent. will be based on image 3 The comparison sachet is also filled with the same amount of granular laundry detergent. The sachets are manually packed one on top of the other in containers for shipping. After reaching the destination, the number of film punctures or lost seals is counted and multiplied by the total number of bags to determine the defect rate as follows:

[0067] Table 2

[0068]

Example 1

Compare sachet A

defect rate in ppm

0

2137

[0069] The sachets of the present invention exhibit reduced quality defects during shipment compared to standard sachets having substantially 90° angled volume corners.

[0070] Those skilled in the art will appreciate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com