Rotating type mop capable of being spun-dried to remove water

A rotary mop and rotary technology, applied in the direction of cleaning carpets, floors, cleaning equipment, etc., can solve the problems of wasting human and material resources, increasing the economic burden of consumers, saving human and material resources, and reducing economic Affordable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

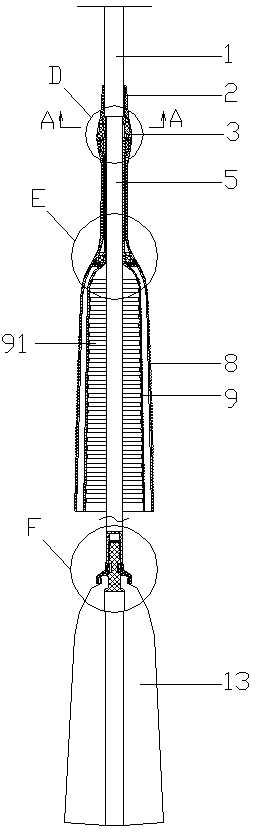

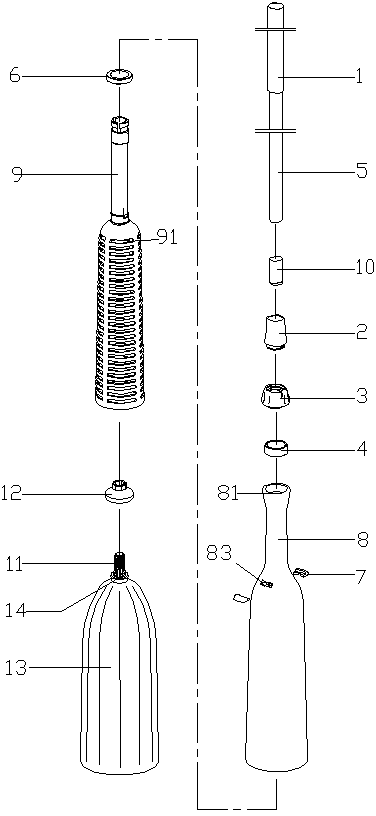

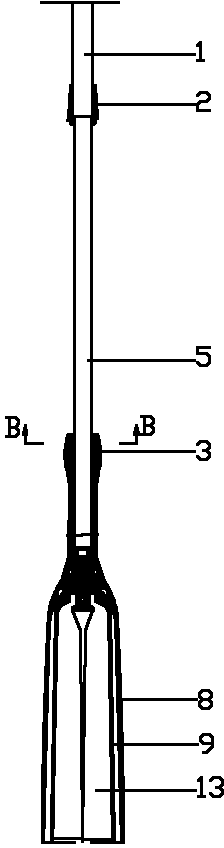

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0029] see Figure 1 to Figure 14 , The embodiment of the present invention includes a rotary mop rod mechanism, a dehydration mechanism, and a mop head mechanism.

[0030] The rotary mop rod mechanism includes an upper tube 1, a sheath 2, a lower tube 5, a tube plug 10 and a rotary drive mechanism. The sheath 2 is fixedly set on the lower end of the upper tube 1, and the lower half of the upper tube 1 is movably set outside the upper half of the lower tube 5. The rotary drive mechanism is placed in the tube of the upper tube 1 and the lower tube 5. The driving part of the rotary drive mechanism is fixedly connected in the tube of the upper tube 1, and the transmission part is fixedly connected in the tube of the lower tube 5. The rotary drive mechanism connects the upper tube 1 and the lower tube. The tubes 5 are movably connected together, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com