Fine filter structure

A technology of fine filtration and filtration components, applied in the direction of filtration circuit, filtration separation, fixed filter element filter, etc., can solve the problems of slippery surface, reduced water permeability and air permeability of the filter screen 23, troubles in use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

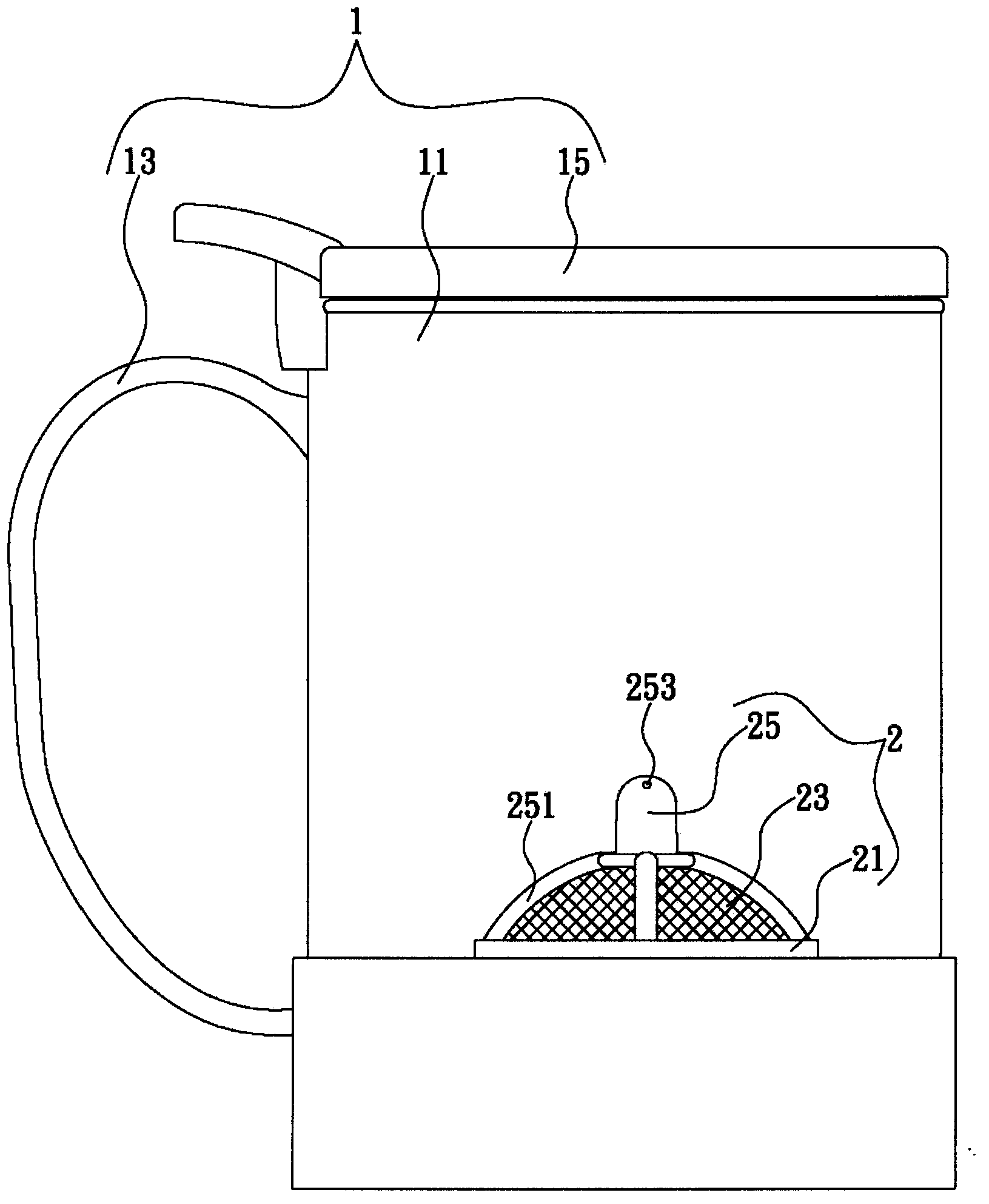

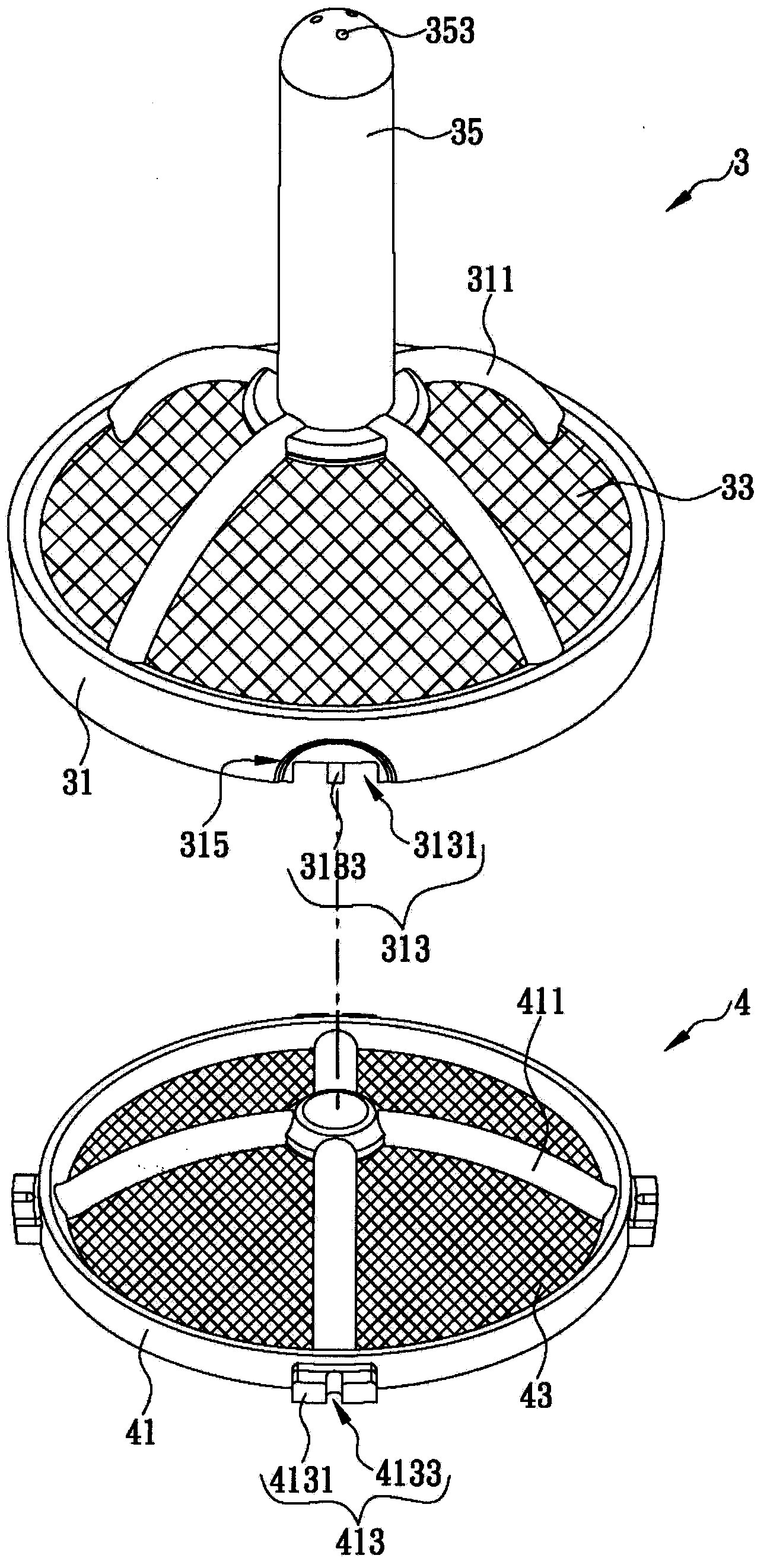

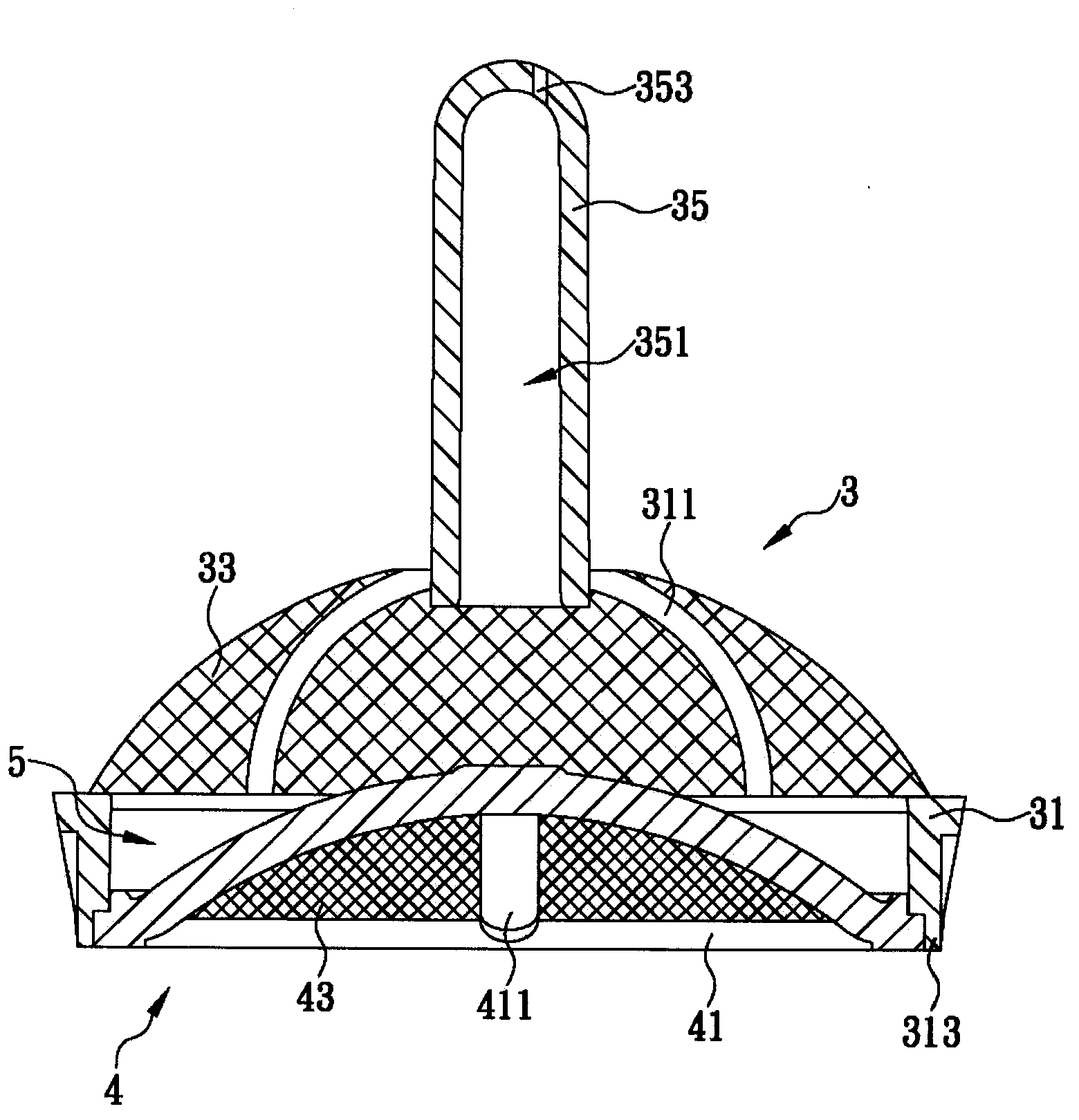

[0016] The present invention is a fine filter structure, which is installed in the cup of a brewing container, please refer to figure 2 As shown, the fine filtration structure includes a primary extraction filter assembly 3 and a primary extraction filter assembly 4. In an embodiment of the present invention, the primary extraction filter assembly 3 includes an upper frame body 31, a coarse mesh filter screen 33 And a cylinder 35, wherein the upper frame body 31 is circular, and its center is transparent, and the top side of the upper frame body 31 is provided with a plurality of first ribs 311, the first ribs 311 One end of the upper frame body 31 is fixed to the upper frame body 31, and the other end is bent and extended toward the upper center of the upper frame body 31. The bottom side of the upper frame body 31 is provided with a plurality of first assembly parts 313. In this embodiment, the bottom side of the upper frame body 31 faces toward the top side, and a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com