Twin-screw electric screw press

An electric screw and press technology, which is applied to the driving device of the forging press and other directions, can solve the problems that restrict the development of large electric screw presses, the poor ability of the slider to bear eccentric loads, and the difficulties in hoisting, transportation and manufacturing. Multi-die forging, eliminating lateral pressure, easy transportation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

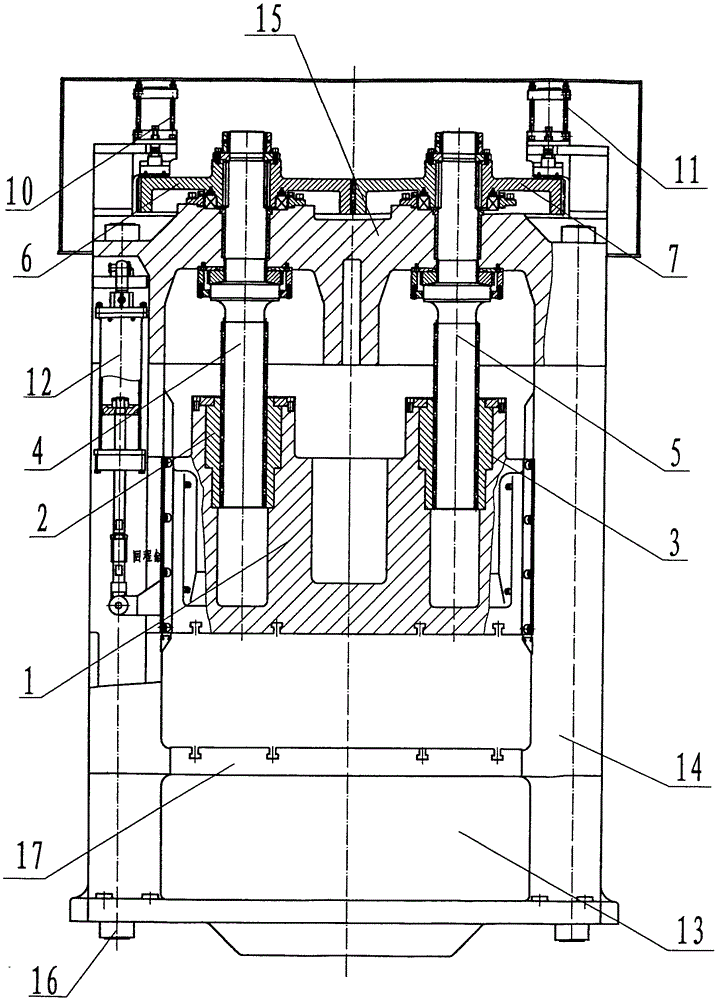

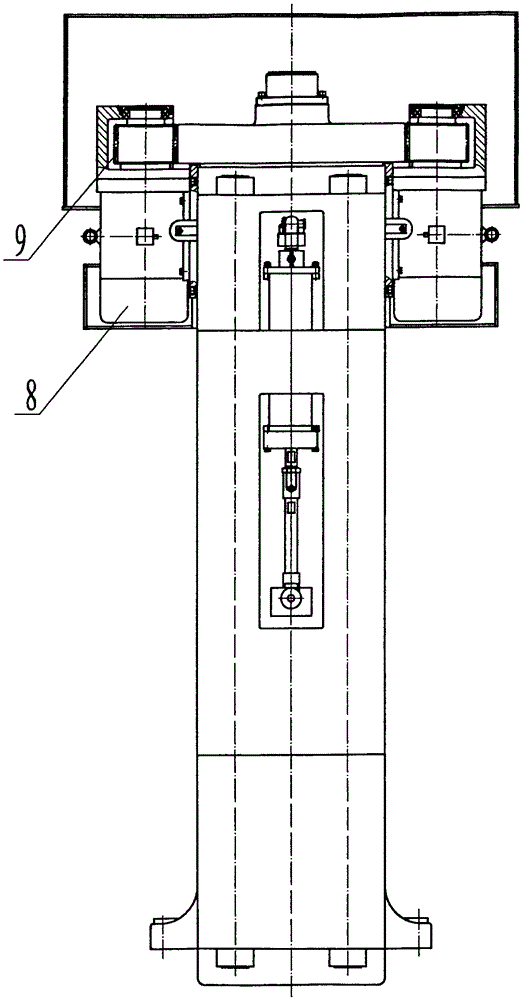

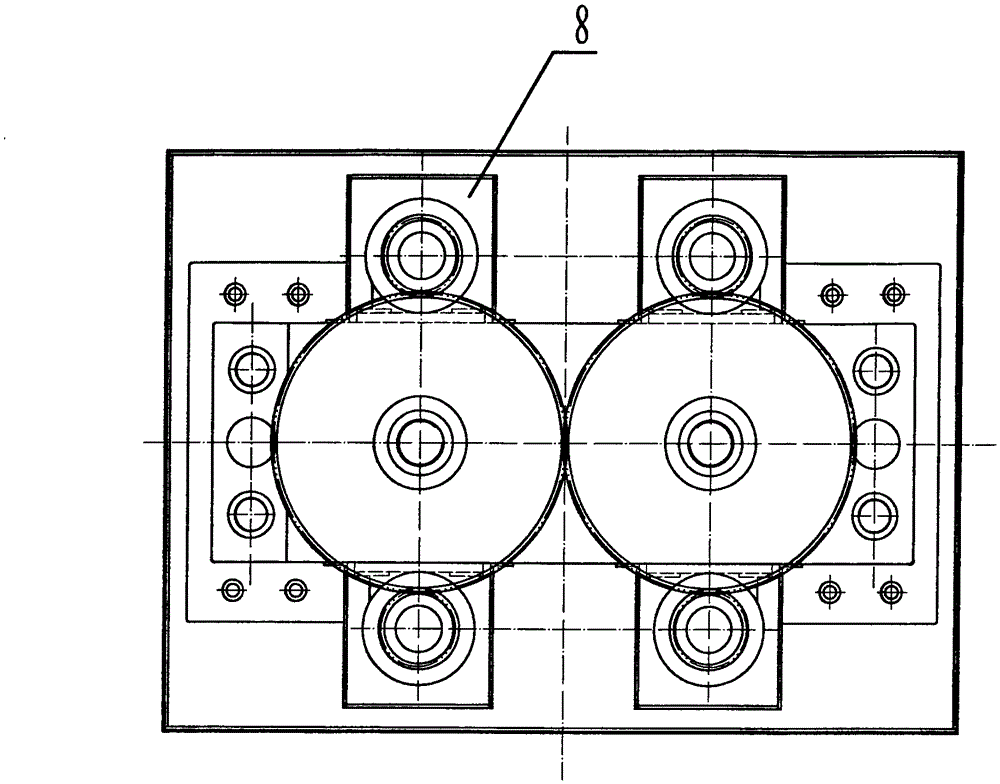

[0019] exist Figure 1 ~ Figure 3 Among them, the twin-screw electric screw press of the present invention includes a frame, a slider 1 installed on the frame guide rail, a left copper nut 2 and a right copper nut 3 embedded in the slider, which are installed on the frame and installed respectively The left screw rod 4 and the right screw rod 5 on the left copper nut and the right copper nut are respectively installed on the left gear type flywheel 6 and the right gear type flywheel 7 at the upper ends of the left screw rod and the right screw rod, and four vertically mounted on the frame. Motor 8, installed on each motor output shaft and two left drive gears 9 and two right drive gears respectively engaged with the left gear type flywheel and the right gear type flywheel, respectively located on the left gear type flywheel and the right gear type flywheel Above and the left flywheel brake 10, the right flywheel brake 11 installed on the frame, the return cylinder 12 installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com