Damp-proof shaving board low in absorbent thickness expansion rate and manufacturing method thereof

A production method and technology of particleboard, applied to other home appliances, pretreatment of molding materials, household components, etc., can solve the problems of furniture performance and aesthetic decline, shortened service life, etc., and achieve low water absorption thickness expansion rate and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

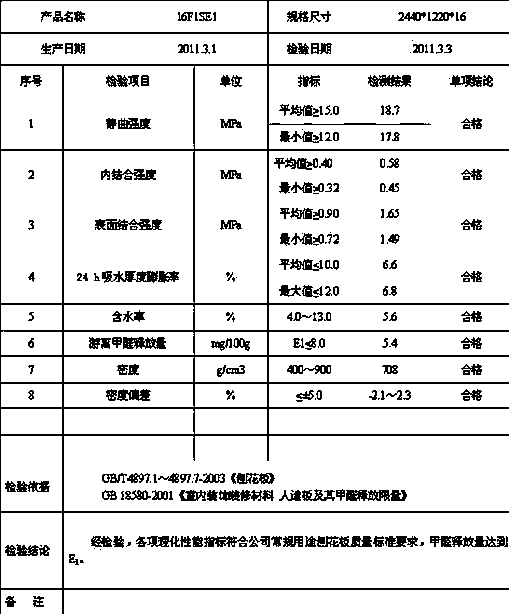

[0030] First, the shavings are prepared by conventional manufacturing processes, and then the glue is adjusted, which is divided into surface layer raw materials and core layer raw materials for glue adjustment respectively. The mass percentage is 1.4-1.60%, and the moisture content of the surface layer is controlled: 9-14%. According to the actual moisture content, an appropriate amount of water is added and stirred, and the content of the surface layer of shavings is calculated according to the density of the finished board to be manufactured; Including core layer shavings, glue mass percentage 8-10%, curing agent mass percentage 1.3-2%, paraffin mass percentage 0.7-1.00%, control the moisture content of the core layer: 4-8%, after adding appropriate amount of water according to the actual moisture content Stir, wherein the glue is preferably E0 or E1 grade particleboard synthetic resin adhesive, and the content of the core layer shavings is calculated according to the densit...

Embodiment 2

[0046]First, the shavings are prepared by a conventional manufacturing process, and then the glue is adjusted, which is divided into surface layer raw materials and core layer raw materials to adjust the glue respectively. The mass percentage is 1.4-1.7%, and the moisture content of the surface layer is controlled: 9-14%, depending on the actual moisture content, adding an appropriate amount of water and then stirring, wherein the content of the surface layer of shavings is calculated according to the density of the finished board to be manufactured; the core layer Raw materials include core layer shavings, glue mass percentage 9.2-9.6%, curing agent mass percentage 1.4-1.8%, paraffin mass percentage 0.7-1.1%, control the moisture content of the core layer: 4-8%, add appropriate amount of water depending on the actual moisture content Finally, stir, wherein the glue is preferably E0 or E1 grade particleboard synthetic resin adhesive, and the content of the core layer shavings i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com