Self-rearranging mortise and tenon joint

A self-resetting and mortise-and-mortise technology, which is applied to the reinforcement of beam-column mortise-and-tenon joints in new wooden structures, mortise-and-mortise joints, and beam-column mortise-and-tenon joints, can solve the problems of difficult restoration, difficult replacement and maintenance, and high repair costs. Significance and economic benefits, reduced maintenance and repair costs, and the effect of avoiding overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

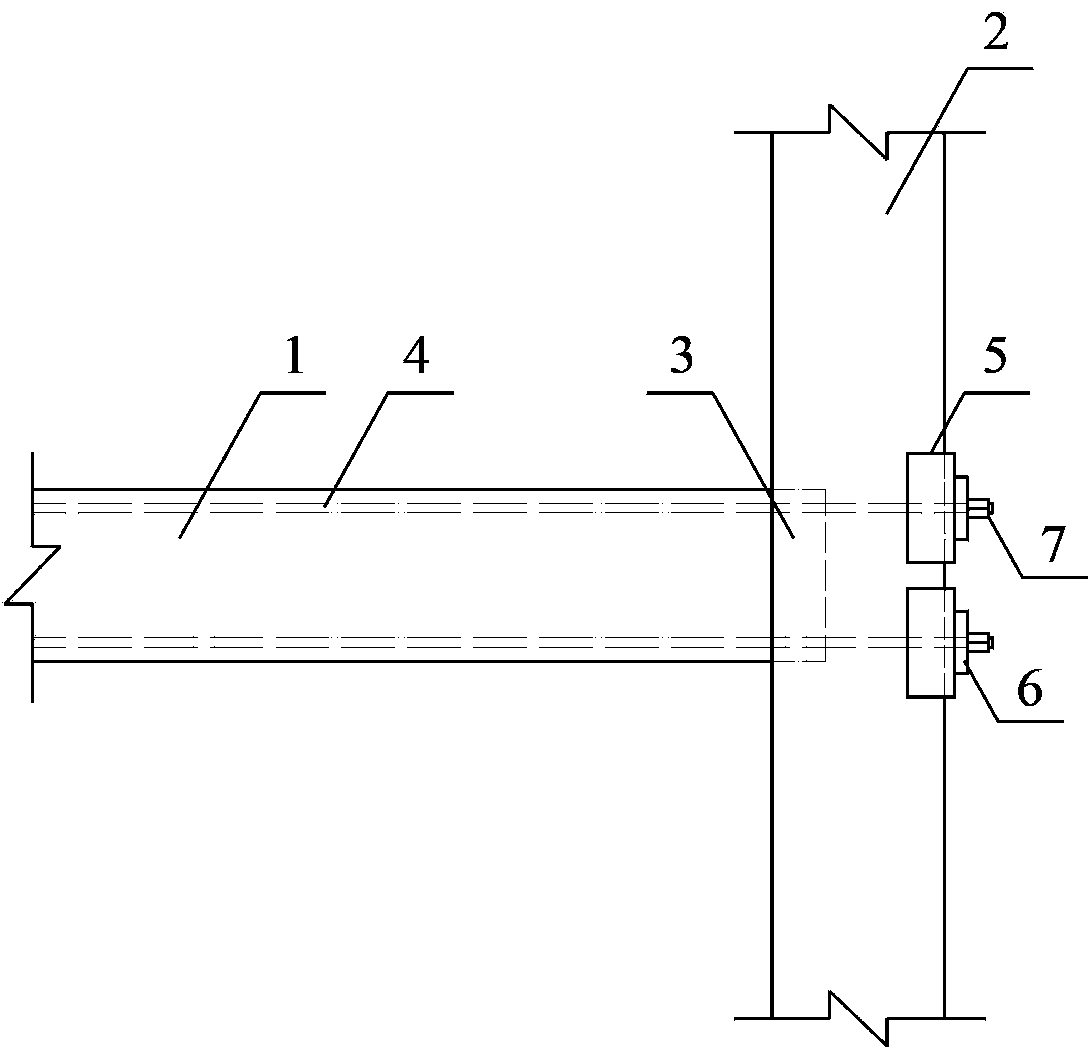

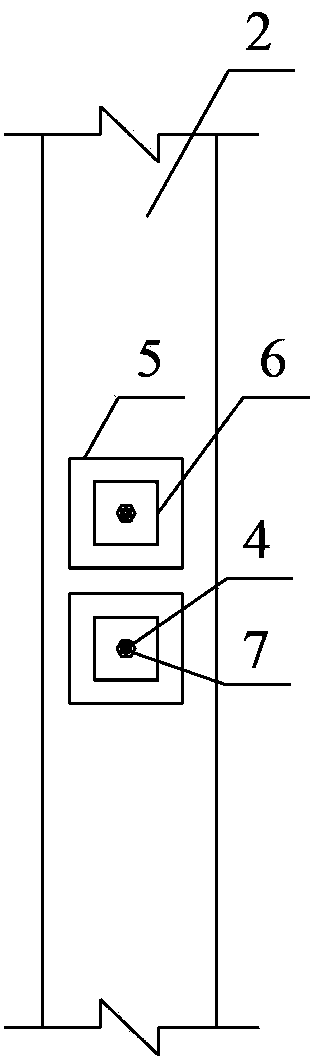

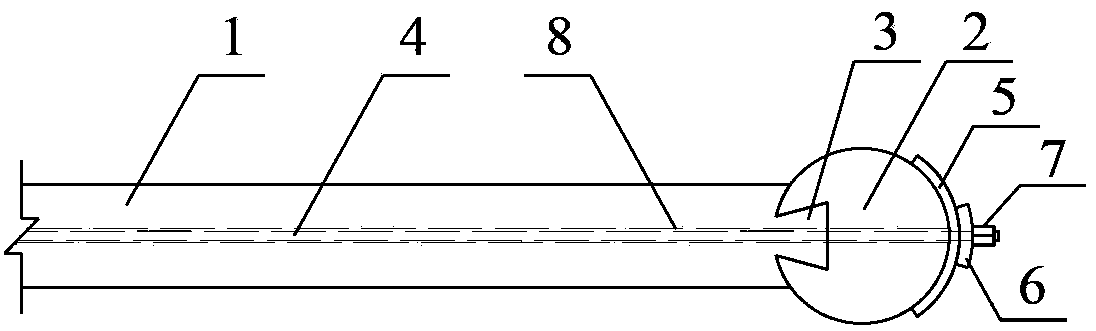

[0029] like figure 1 , 2 Shown in and 3, a kind of self-resetting tenon and mortise joint, including wooden beam 1, wooden column 2, tenon and tenon joint 3 and prestressed tendon 4 between the beam and column, between the wooden beam 1 and the wooden column 2, through the tenon and tenon joint The node 3 is connected, the prestressed tendon 4 runs through the wooden beam 1 and the wooden column 2 along the longitudinal direction of the wooden beam, and the end of the prestressed tendon 1 passes through the anchor plate 5, the anchor pad 6 and the anchor 7, and is on the back of the wooden column 2. Fix it to one side of the wooden beam 1.

[0030] The cross section of the wooden beam 1 is rectangular, and the cross section of the wooden column 2 is circular.

[0031] The material of the wooden beam 1 is one of logs, sawn timber, glulam (glulam), laminated veneer lumber (LVL), parallel-slice glulam (PSL), laminated wood-slice glulam (LSL), and other engineered woods . The ...

Embodiment 2

[0036] like Image 6 As shown in the figure, a self-resetting mortise and tenon joint, the rest of the structure is the same as that of Embodiment 1, the difference is that the cross section of the wooden column 2 is square.

Embodiment 3

[0038] like Figure 7 and 8 As shown, a self-resetting mortise and tenon joint, the rest of the structure is the same as that of Embodiment 1, the difference is that: the tenon and mortise joint 3 is a through tenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com